A steel pipe automatic palletizer

A palletizing machine and palletizing technology, which is applied in the field of steel pipe palletizing equipment, can solve the problems such as the difficulty in stacking steel pipes, the difficulty in automatic production, and the high labor intensity, so as to improve labor production efficiency, facilitate inventory management, and have good consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

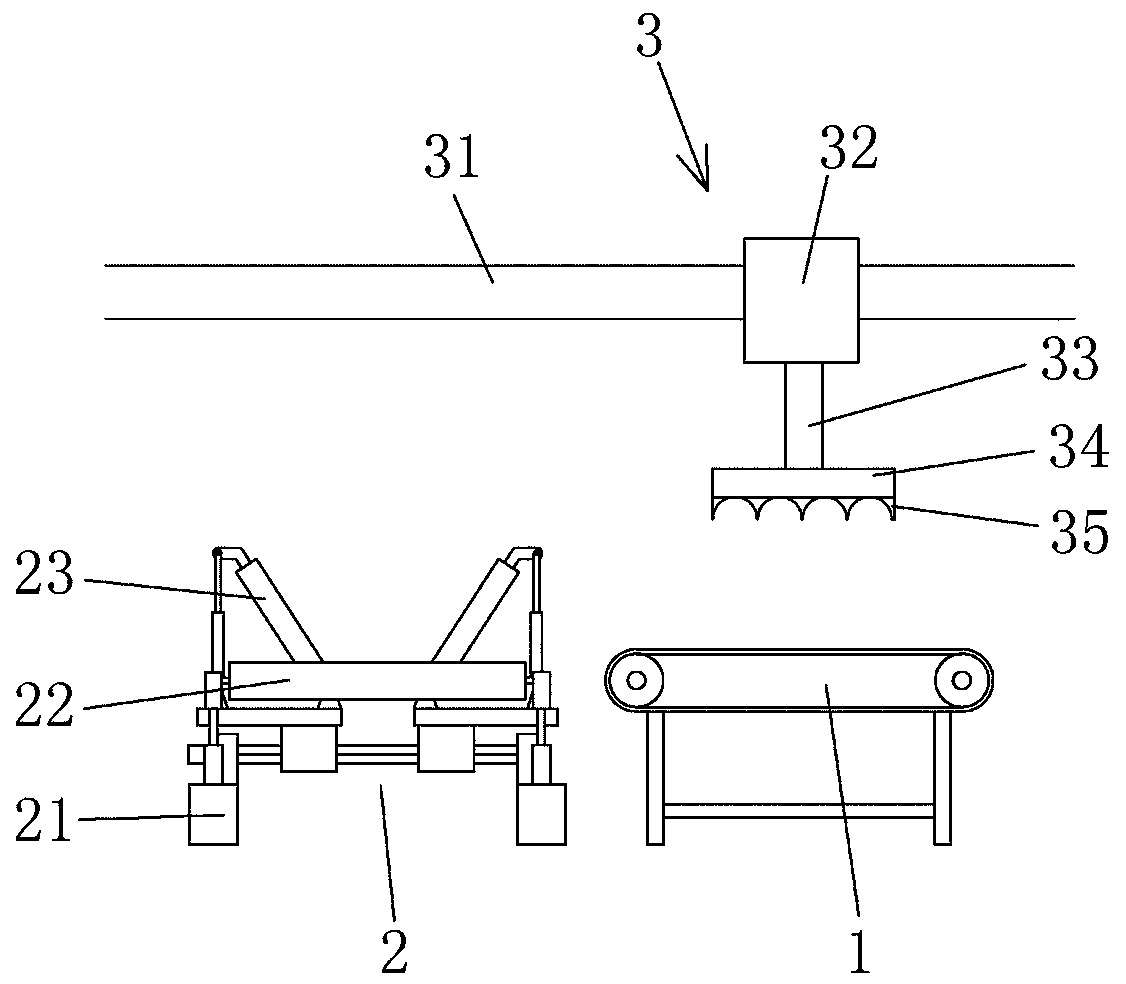

[0021] Example: such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a steel pipe automatic palletizer includes a steel pipe conveying line 1, a palletizing conveying line 2 and a steel pipe magnetic device 3, and the conveying direction of the steel pipe conveying line 1 is perpendicular to the conveying direction of the palletizing conveying line 2 , the steel pipe magnetic device 3 transfers the steel pipe on the steel pipe conveying line 1 to the palletizing conveying line 2 .

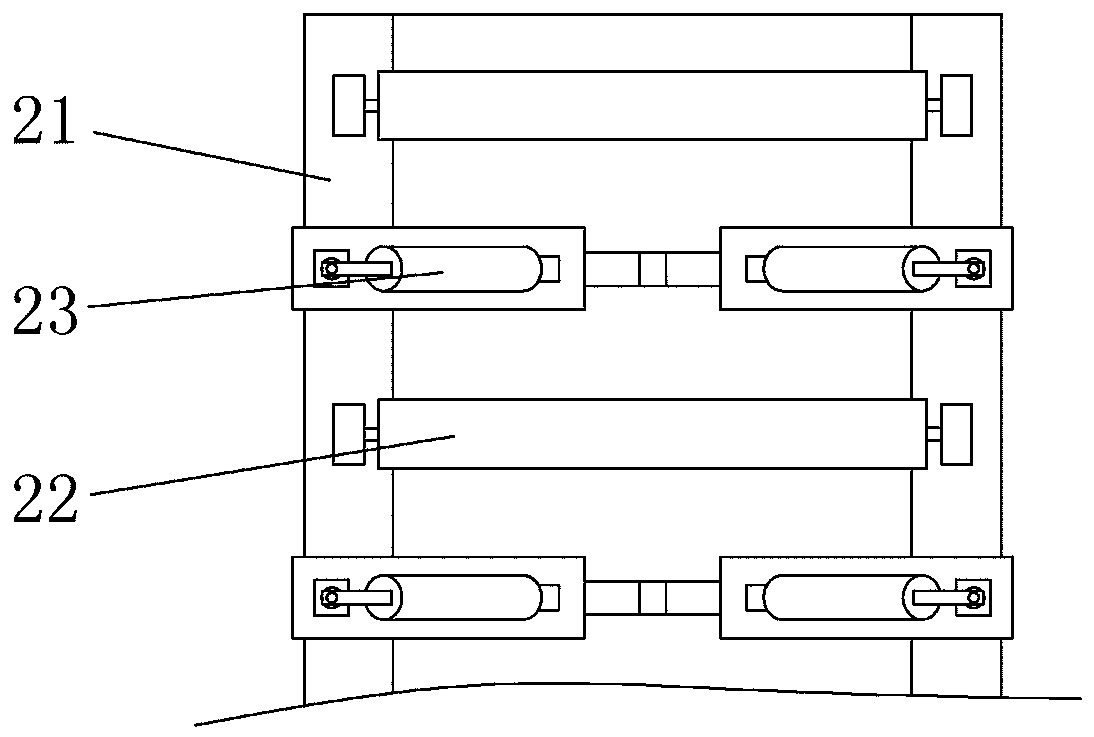

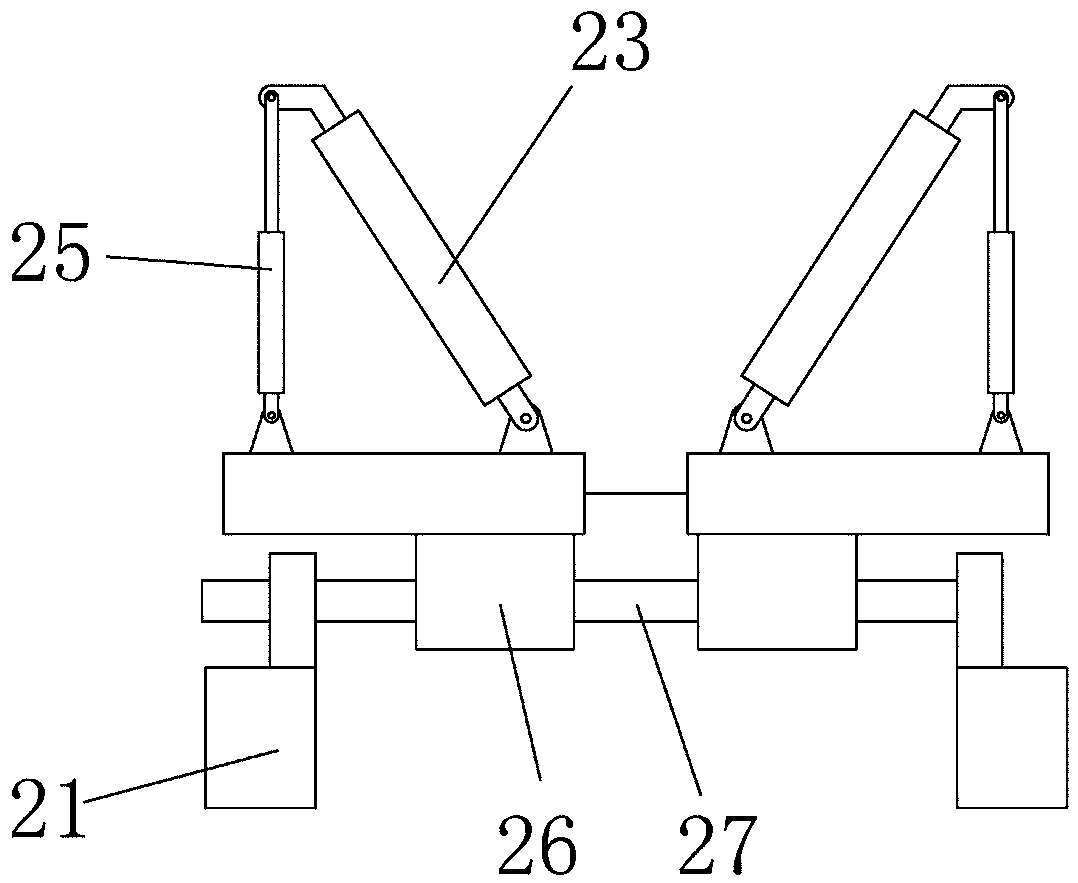

[0022] The stacking conveying line 2 includes a frame 21, a conveying roller 22 and a stacking roller 23, and the surfaces of the conveying roller 22 and the stacking roller are covered with a buffer layer, and the buffer layer is a rubber layer or a polyurethane layer. The conveying roller 22 is a driving roller, distributed along the conveying direction of the palletizing conveying line 2 , the conveying roller 22 is arranged horizontally and its axis is perpendicular to the conveyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com