Graphite boat for film coating

A technology of graphite boat and coating area, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of too thin, uneven temperature conduction, large volume of graphite boat, etc., and reduce the proportion of failed pieces , The effect of improving the uniformity of the coating film thickness and improving the average efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] Preferred embodiment one:

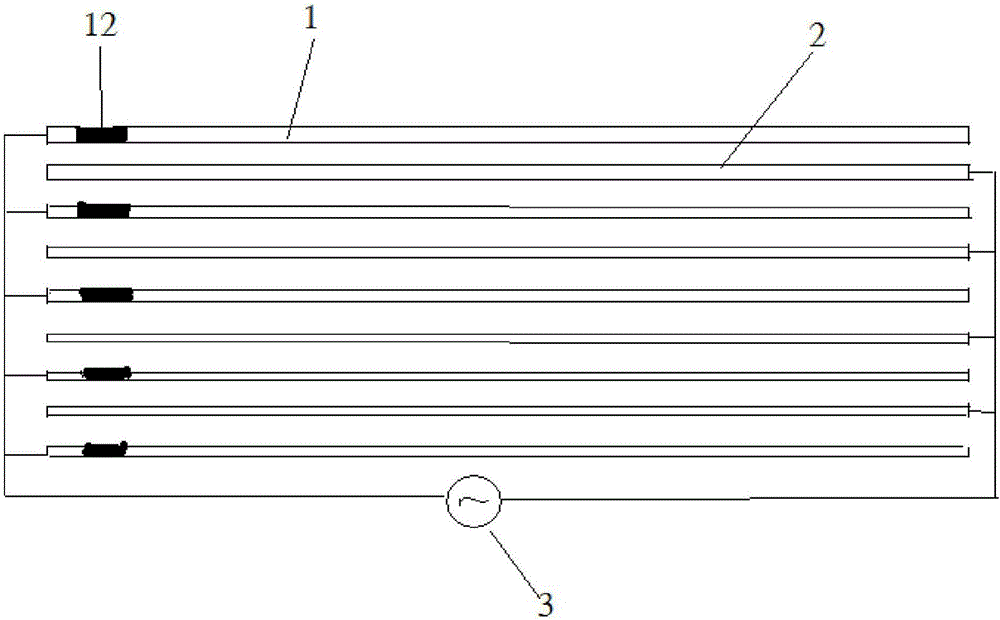

[0025] The preferred embodiment provides a graphite boat for film coating. Such as figure 2 As shown, the graphite boat for coating includes a plurality of first graphite boats 1, a plurality of second graphite boats 2, and a radio frequency generator 3 for connecting with electrodes.

[0026] The first graphite boat 1 and the second graphite boat 2 are arranged in parallel and spaced apart. Each second graphite boat 2 is connected to one of the electrodes of the graphite boat, and each first graphite boat 1 is connected to the other electrode of the graphite boat. One electrode connection.

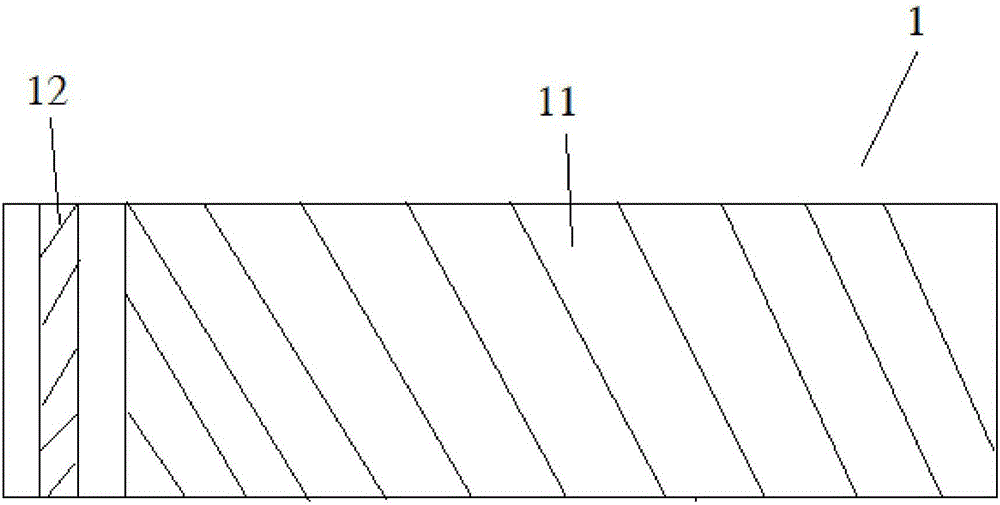

[0027] Such as figure 1 As shown, the first graphite boat 1 has a silicon wafer coating area 11 and a specific area 12. The specific area 12 is a specific resistivity area, which needs to be processed by a doping process, and the cross section is preferably processed into a rectangle; the length of the specific area 12 is equal to the width of the first gra...

Example Embodiment

[0031] Preferred embodiment two:

[0032] The preferred embodiment provides a graphite boat for film coating. The graphite boat for coating includes 10 first graphite boats and 11 second graphite boats. The resistivity of the second graphite boat is 9×10 -6 Ω.m, the resistivity of the specific area of the first graphite boat (outer boat) outside the graphite boat is 10 -3 Ω.m, the resistivity of the specific area of the first graphite boat (center boat) in the center of the graphite boat is 10 -5 Ω.m, along the center of the graphite boat toward the outside, the resistivity of the specific area of each first graphite boat gradually increases to 10 -3 Ω.m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap