Efficient integral formwork

A formwork, integrated technology, applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, which can solve problems such as troublesome construction, immovability, and complicated use. , to achieve the effect of quick and simple installation, enhanced transfer shape, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

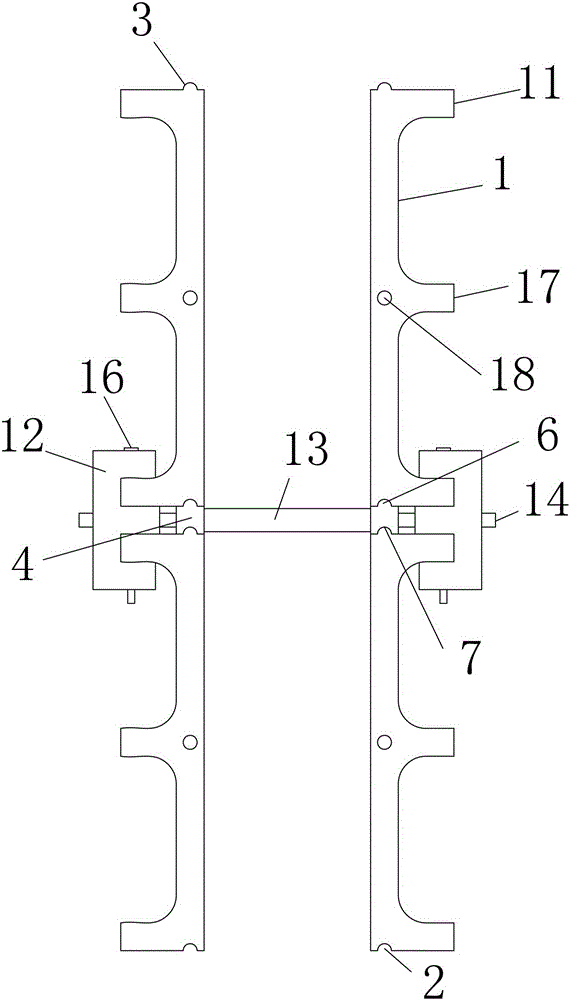

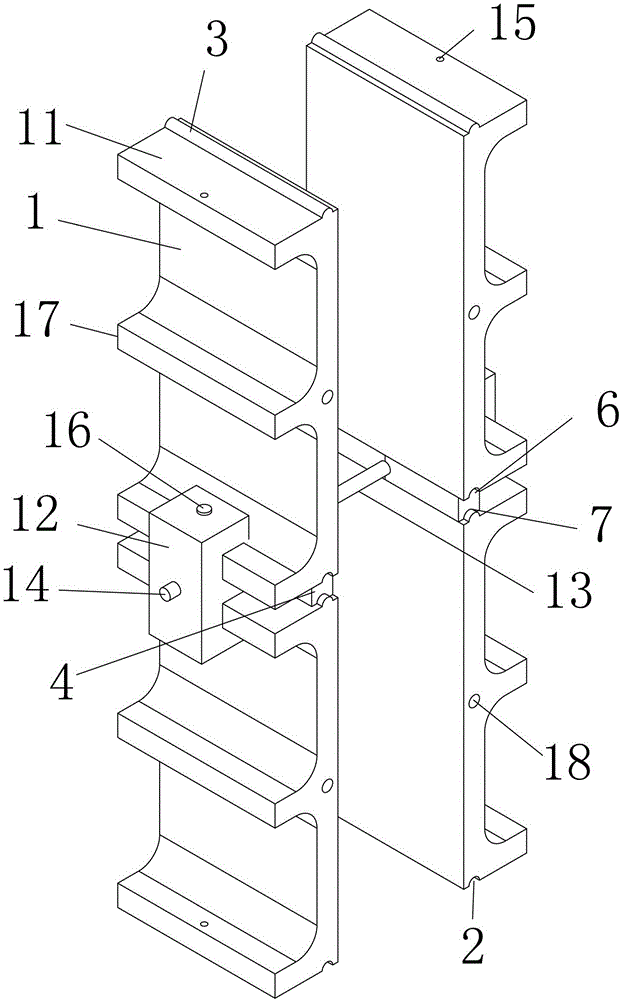

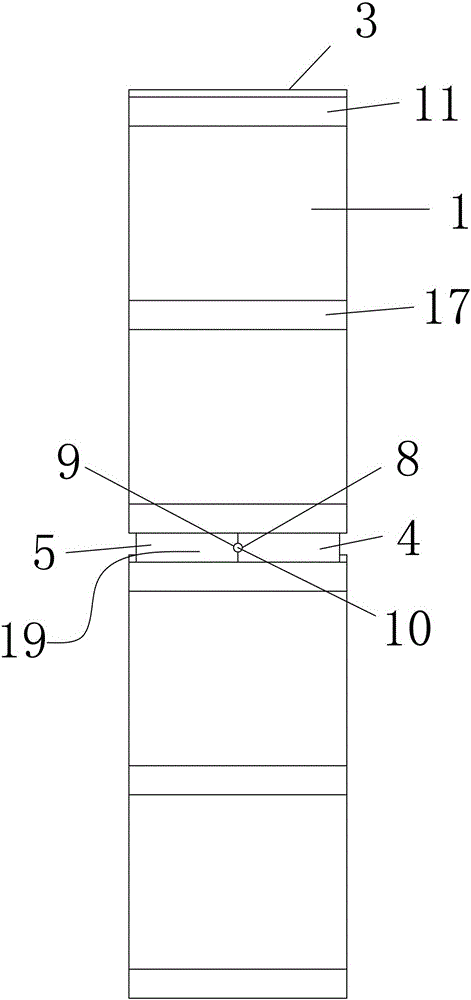

[0018] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] Depend on Figure 1 to Figure 12 Given, the technical solution of the present invention is to include templates 1 that are butted up and down sequentially, the opposite surfaces of the two templates 1 that are connected up and down are respectively provided with a longitudinal first groove 2 and a first protrusion 3, and the upper and lower two butt joints Between the formwork 1 of the template 1, a tie hole opposite block 19 is set, and the tie hole opposite block 19 includes a first opposite block 4 and a second opposite block 5, and the first opposite block 4 and the second pair The upper and lower end surfaces of the block 5 are respectively provided with a second protrusion 6 cooperating with the first groove 2 and a second groove 7 cooperating with the first protrusion 3, the first opposing block 4 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com