A mobile power supply device for a trolley line

A technology for a mobile power supply and a trolley wire, which is applied in the field of movable power supply devices for trolley lines, can solve the problems of affecting the work efficiency, unable to set up a reliable temporary power supply box and other power supply devices, inconvenient maintenance workers, etc. Efficiency and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

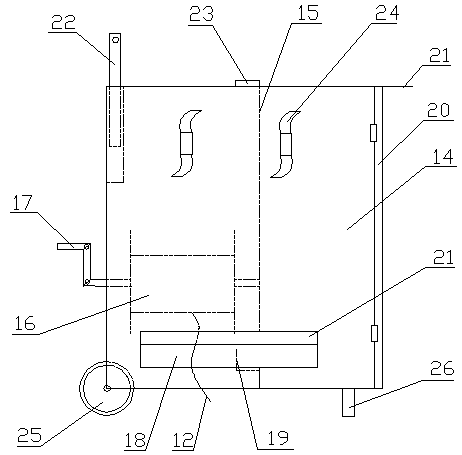

[0024] Such as figure 1 A movable power supply device for a trolley line is shown, including a power box 14 provided with a winding device, a power cable 12 wound on the winding device, and a power clip connected to the power cable 12 .

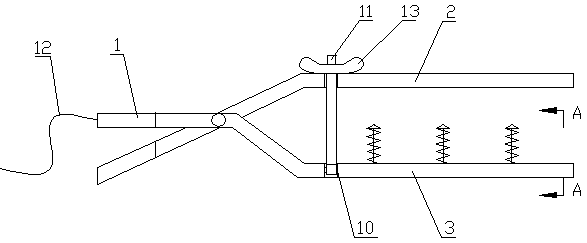

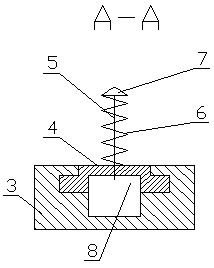

[0025] The power clamp includes an upper splint 2 and a lower splint 3 that are hinged to each other. The upper splint 2 and the lower splint 3 are insulating plates. One side of the hinge point of the upper and lower splints is provided with a tensioning device that pulls the upper splint 2 and the lower splint 3 relative to each other. , the end on the other side of the hinge point is respectively provided with a handle 1 with an insulating sheath, the lower splint 3 and the upper splint 2 are respectively provided with opposite and parallel straight sections, and the straight section an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com