Dust cover for ball joint

A ball-socket joint and dust-proof cover technology, which is applied to pivot connections, bearings, shafts, etc., can solve the problems of reduced sealing performance and inability to completely prevent co-rotation, and achieve the effect of preventing co-rotation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, modes for implementing the present invention will be described.

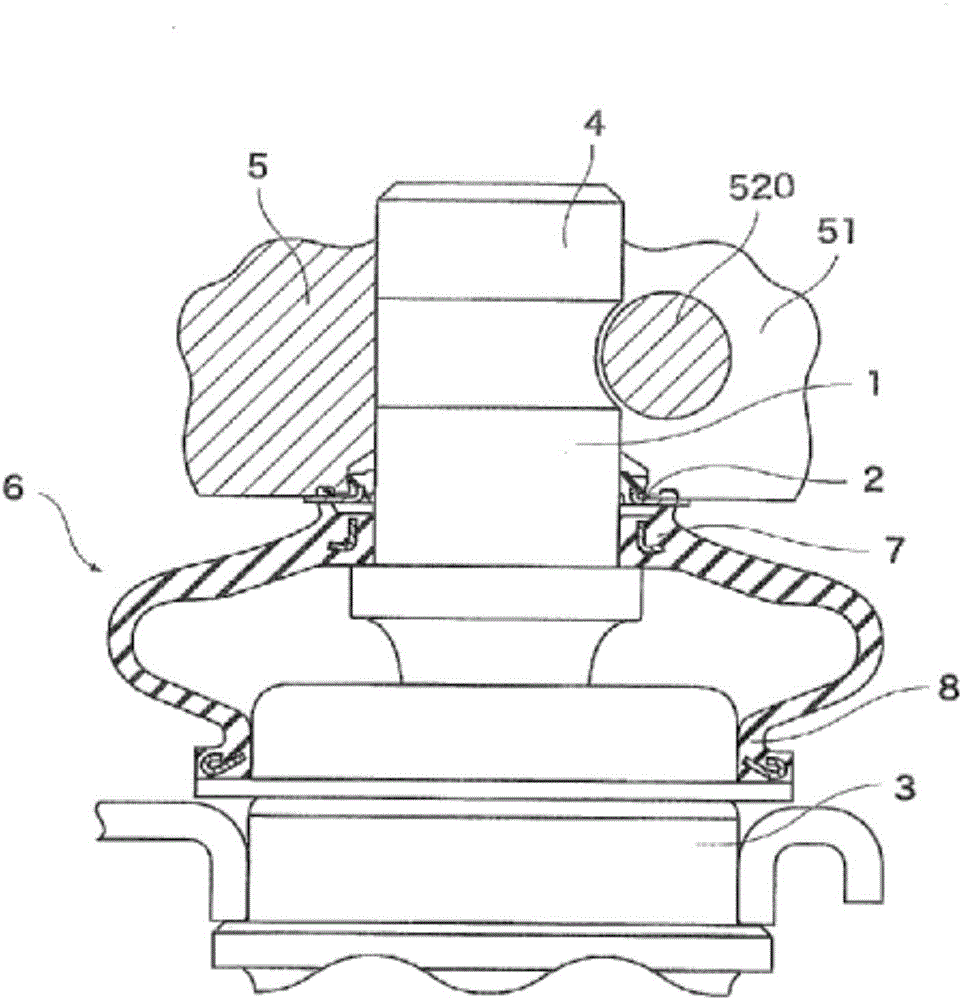

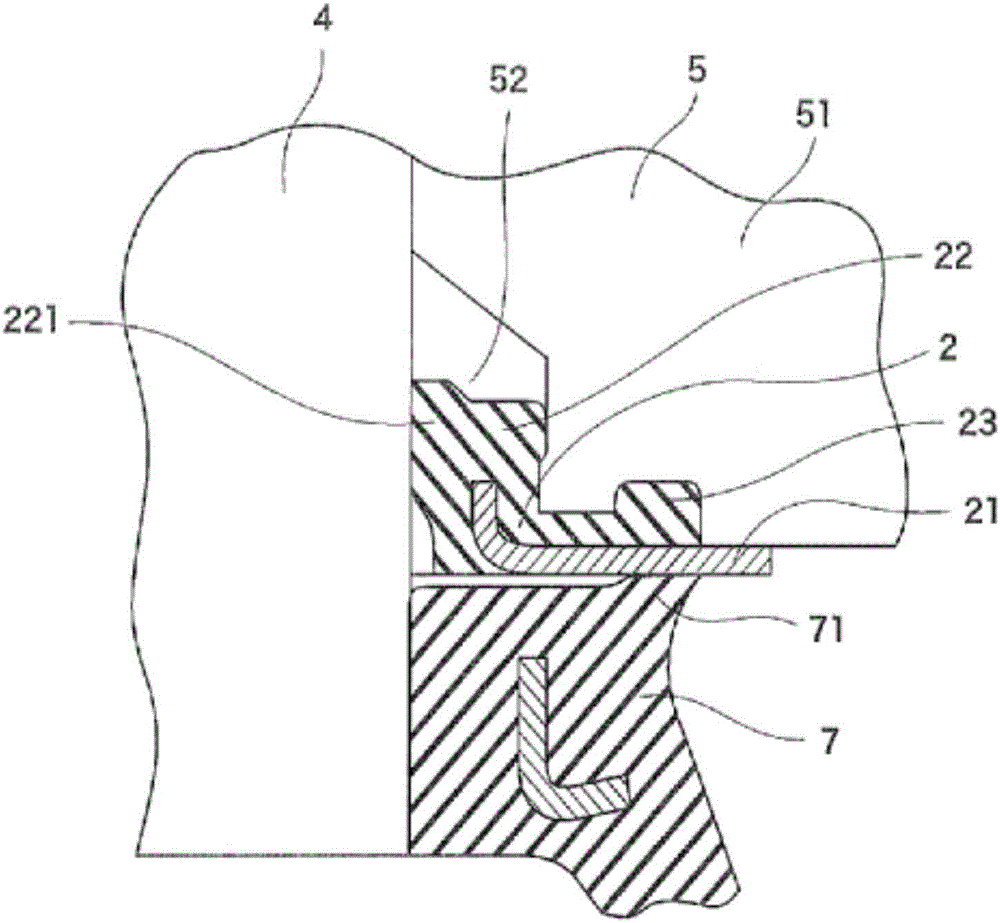

[0049] Such as figure 1 , figure 2 , image 3 as well as Figure 4 As shown, in the ball joint dust cover 6 of the present invention, the ball head formed at one end of the ball stud 1 is held in the ball socket 3, and the shaft 4 at the other end of the ball stud 1 The knuckle 5 is fixed to the knuckle 5 side by fastening the knuckle 5 with a fastening device 520 such as a bolt.

[0050] In addition, the large-diameter opening 8 at one end of the dust cover 6 is fixedly held on the outer peripheral surface of the ball head 3 , and the small-diameter opening 7 at the other end of the dust cover 6 is held on the shaft 4 .

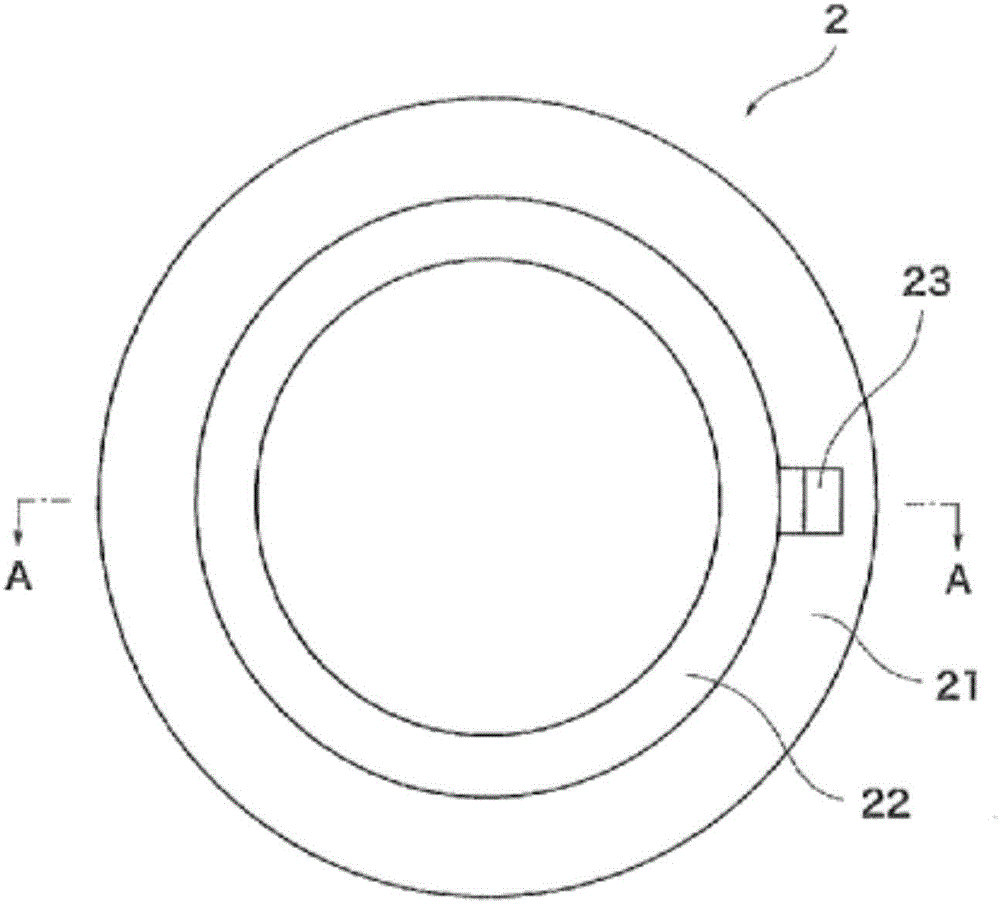

[0051] Furthermore, a basic structure for holding the plate member 2 is provided between the inner peripheral surface of the knuckle 5 on the other end small-diameter opening 7 side and the outer peripheral surface of the shaft 4 .

[0052] This kind of steering knuc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com