Laminated spiral type solid-liquid separator with vertical spiral shafts

A solid-liquid separator and screw shaft technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of inability to accumulate pressure, the dehydrator occupies a large area, and cannot continue to move forward, and achieves simple and convenient structure and operation, and easy to observe. and maintenance, improve the effect of space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

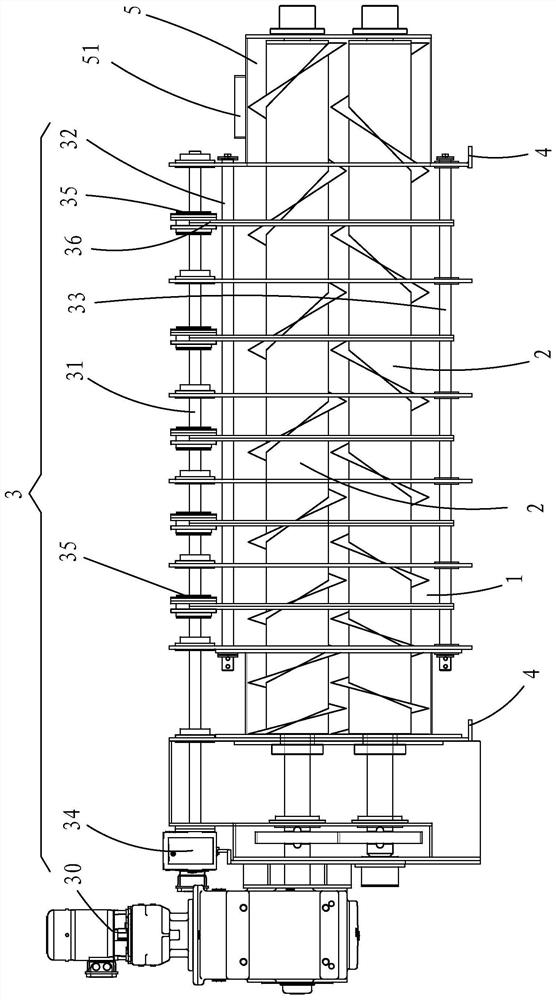

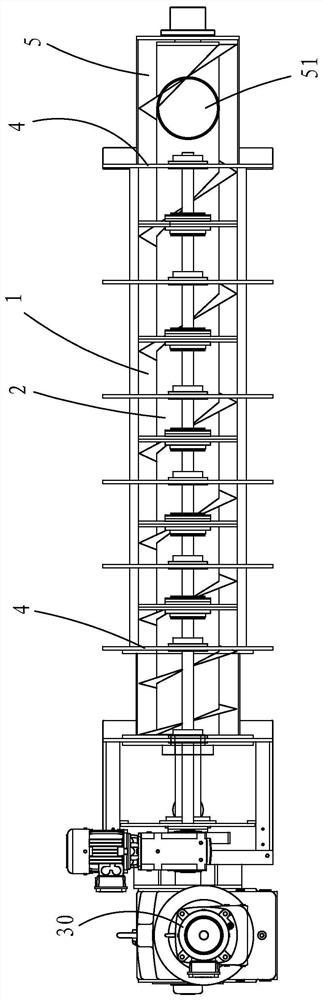

[0051] Such as Figure 1 to Figure 11 As shown, a laminated spiral solid-liquid separator with vertically arranged spiral shafts includes: a filter chamber 1 , a spiral shaft 2 , a driving device 3 , and a plurality of support plates 4 .

[0052] The filter cavity 1, the screw shaft 2 and the driving device 3 are supported and positioned by a plurality of support plates 4; the screw shaft 2 runs through the filter cavity 1; the two ends of the filter cavity 1 are the feed end 11 and the discharge end respectively 12.

[0053] The filter chamber 1 includes two sets of closed ring sheets, the first closed ring sheet group 13 is driven by the driving device 3 to move, and the second closed ring sheet group 14 is connected to the support plate 4 and remains fixed. Gaskets (not shown) are arranged between the adjacent two closed rings of the second closed ring group 14, and the thickness of the gasket is greater than the thickness of the first closed rings 13, so that the adjacent...

no. 2 example

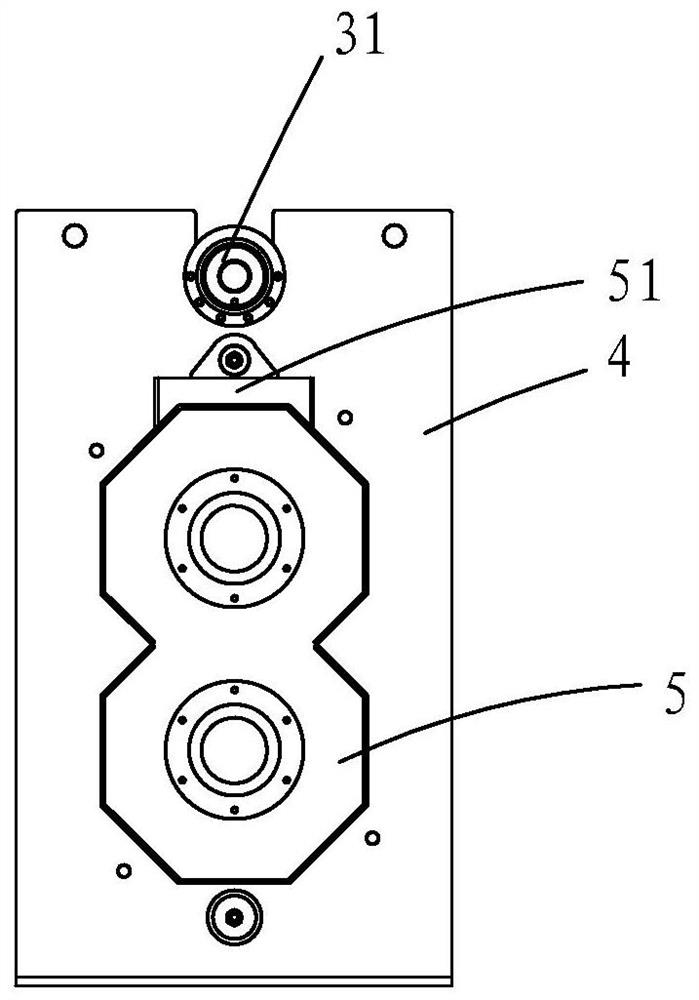

[0064] Such as Figure 12 to Figure 14 As shown, in this embodiment, the upper half of the support plate 4 of the feed end 11 at the end of the filter cavity 1 is connected to a cylindrical feed box 5, and the end of the screw shaft 2 at the top extends into the cylindrical feed In the box 5, the feature of the screw shaft section in the feeding box is: a baffle plate 6 is set between the starting point 211 and the end point 212 of the first screw blade 21 from the end of the screw shaft 2 to divide the screw shaft 2 into two regions One side of the baffle plate 6 is connected to the central axis of the screw shaft 2, and the other side is fitted with the wall of the cylindrical feed box 5 to form a seal; the outer edge of the first helical blade 21 is in contact with the cylindrical feed box The inner walls of the material box 5 are attached to each other; the distance from the starting point 211 to the end point 212 of the first helical blade 21 is greater than the axial wid...

no. 3 example

[0068] The difference between this embodiment and the second embodiment is that the back side of the baffle plate 6 and the area formed between the end point 212 and the starting point 211 of the first screw blade 21 are columns 61, which are connected with the box of the cylindrical feed box 5. Internal wall fit, such as Figure 15 shown.

[0069] The baffle plate 6 of the helical shaft section in the cylindrical feed box 5 rotates with the helical shaft 2, and the advancing direction of the material is the front side, and vice versa is the back side. The columnar body 61 on the back of the baffle plate 6 can be a hollow columnar body or a solid columnar body, which can make the material generate continuous positive pressure and prevent the material from stagnating in the area where the columnar body 61 is located.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com