A lead frame squeegee and its working process

A technology of lead frame and squeegee machine, which is applied in the direction of coating and coating liquid on the surface, etc. It can solve the problems of difficult to guarantee the quality of solder paste, unqualified products, and low work efficiency, so as to improve the quality of coating High efficiency, high pass rate of painting, and high painting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

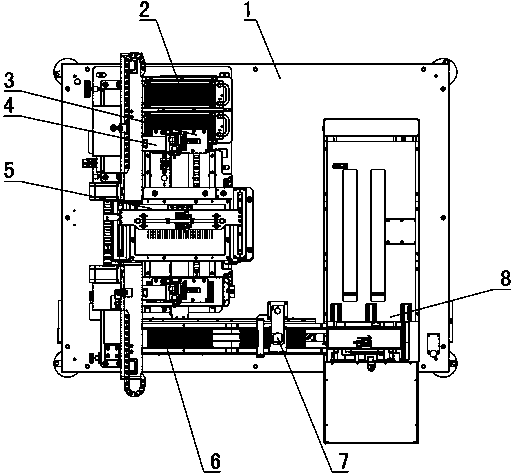

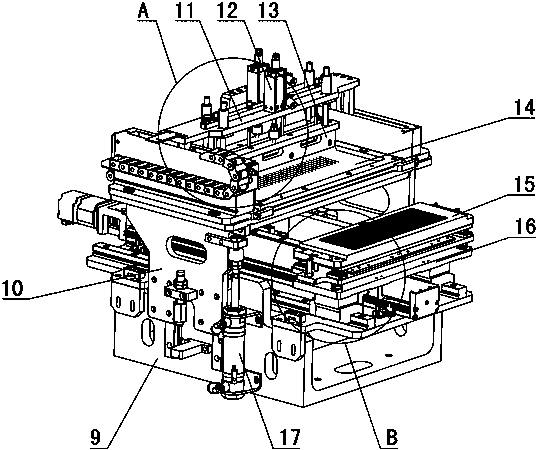

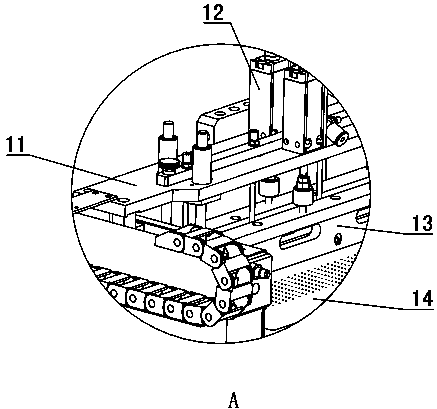

[0039] Figure 1~11 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~11 The present invention will be further described.

[0040] A lead frame scraper machine, comprising a scraper mechanism 5, a stacking mechanism 8 and a control device, the lower side of the scraper mechanism 5 is provided with a lead frame conveying mechanism for conveying the lead frame, and the stacking mechanism 8 is provided with a lead frame conveying mechanism On one side of the lead frame, the lead frame conveying mechanism, the glue scraping mechanism 5 and the stacking mechanism 8 are all connected to the control device, the lead frame conveying mechanism is used to convey the lead frame, and cooperates with the glue scraping mechanism 5 to coat the Apply solder paste, and the stacking mechanism 8 is used to stack the lead frame on the stacking frame 21 . The lead frame conveying mechanism of the lead frame scraping machine cooperates with the scrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com