Roll gap downward pressing regulation device for straightening machine

An adjustment device and technology for straightening machine rolls, applied in the field of straightening machine equipment, can solve the problems of increased load on the adjustment device, high energy consumption, and increased shifting error, so as to improve the precision of roll gap reduction, reduce production costs, Overall low power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with accompanying drawing:

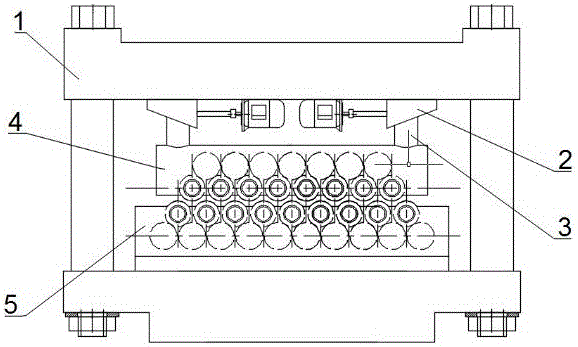

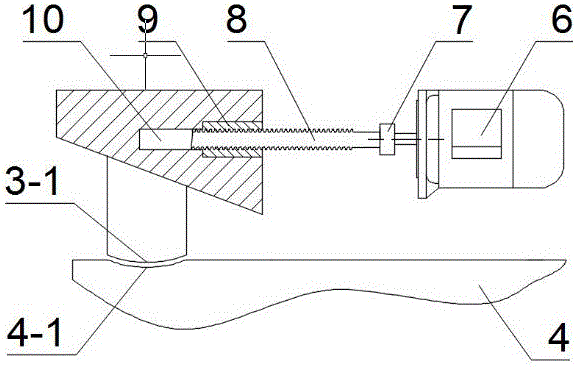

[0015] like figure 1 and figure 2 As shown, the present invention provides a roll gap adjustment device for a straightening machine, which includes two sets of roll gap adjustment devices fixed at the left and right ends of the inlet and outlet of the upper roll system 4 . The roll gap reduction adjustment device includes an upper wedge 2 in contact with the top of the frame 1, the lower wedge 3 and the upper wedge 2 pass through the junction of the slope, and the upper roll system 4 and the lower wedge 3 pass through The joints of the arc surfaces can be rotated at a certain angle. The driving force of the horizontal movement of the upper wedge 2 is driven by the servo motor 6 fixed on the top of the frame 1 to drive the screw 7 for transmission.

[0016] In this embodiment, when the roll gap adjustment device is in use, firstly calculate the required horizontal movement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com