Valve plate manufacturing method

A valve plate and plate body technology, applied in the field of valve plate manufacturing methods, can solve the problems of inability to block fluids, cost money, and cannot be used in high temperature environments, and achieve the effect of simplifying the cutting operation process and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following examples illustrate possible implementations of the present invention, but are not intended to limit the protection scope of the present invention.

[0033] Please refer to Figure 1 to Figure 9 , which shows a preferred embodiment of the present invention, the valve plate manufacturing method of the present invention comprises the following steps:

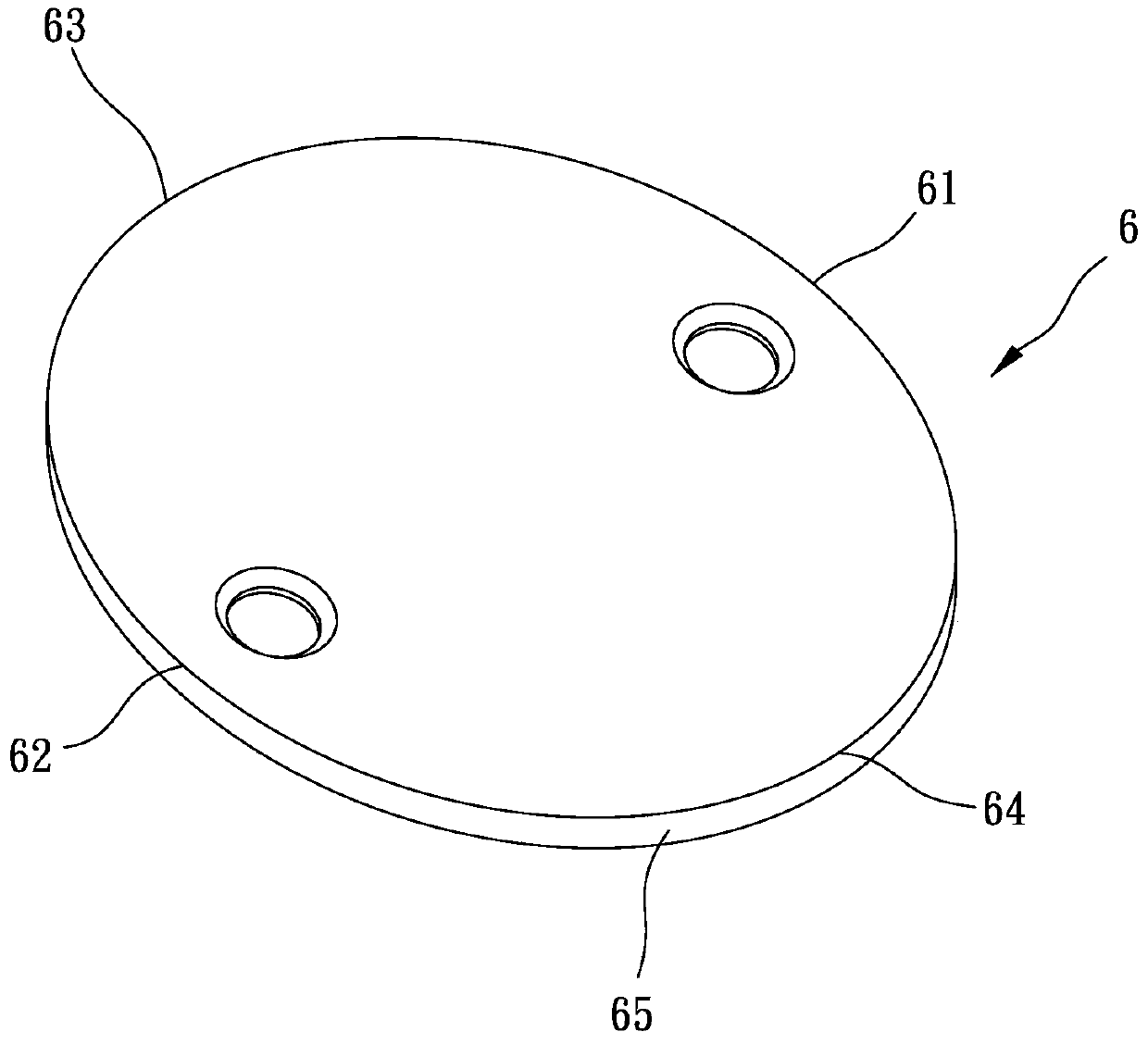

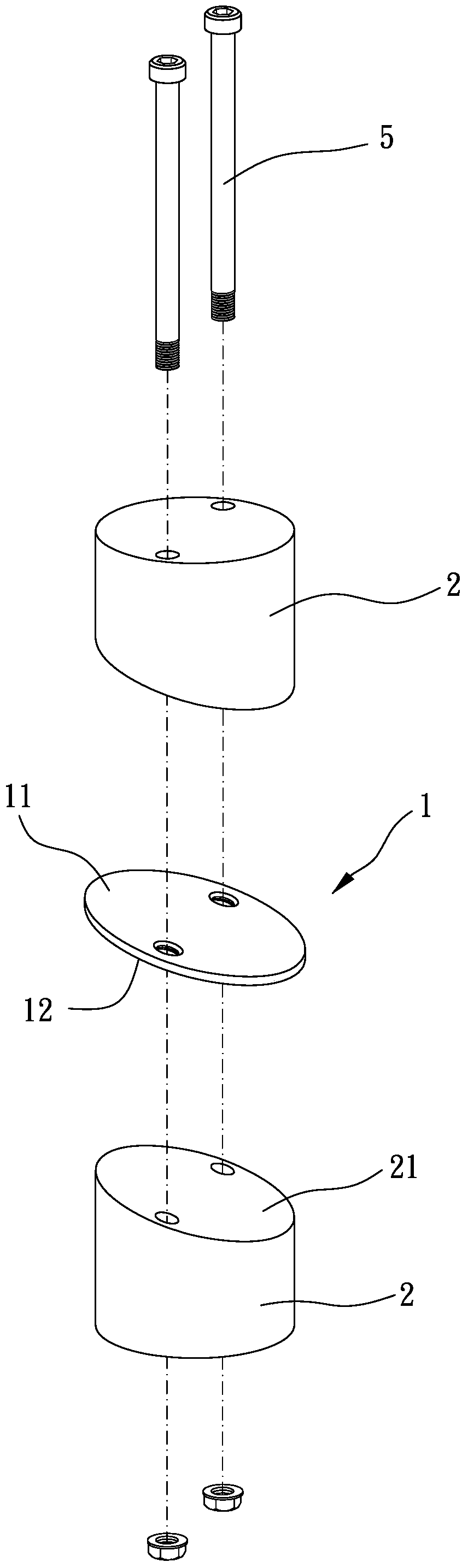

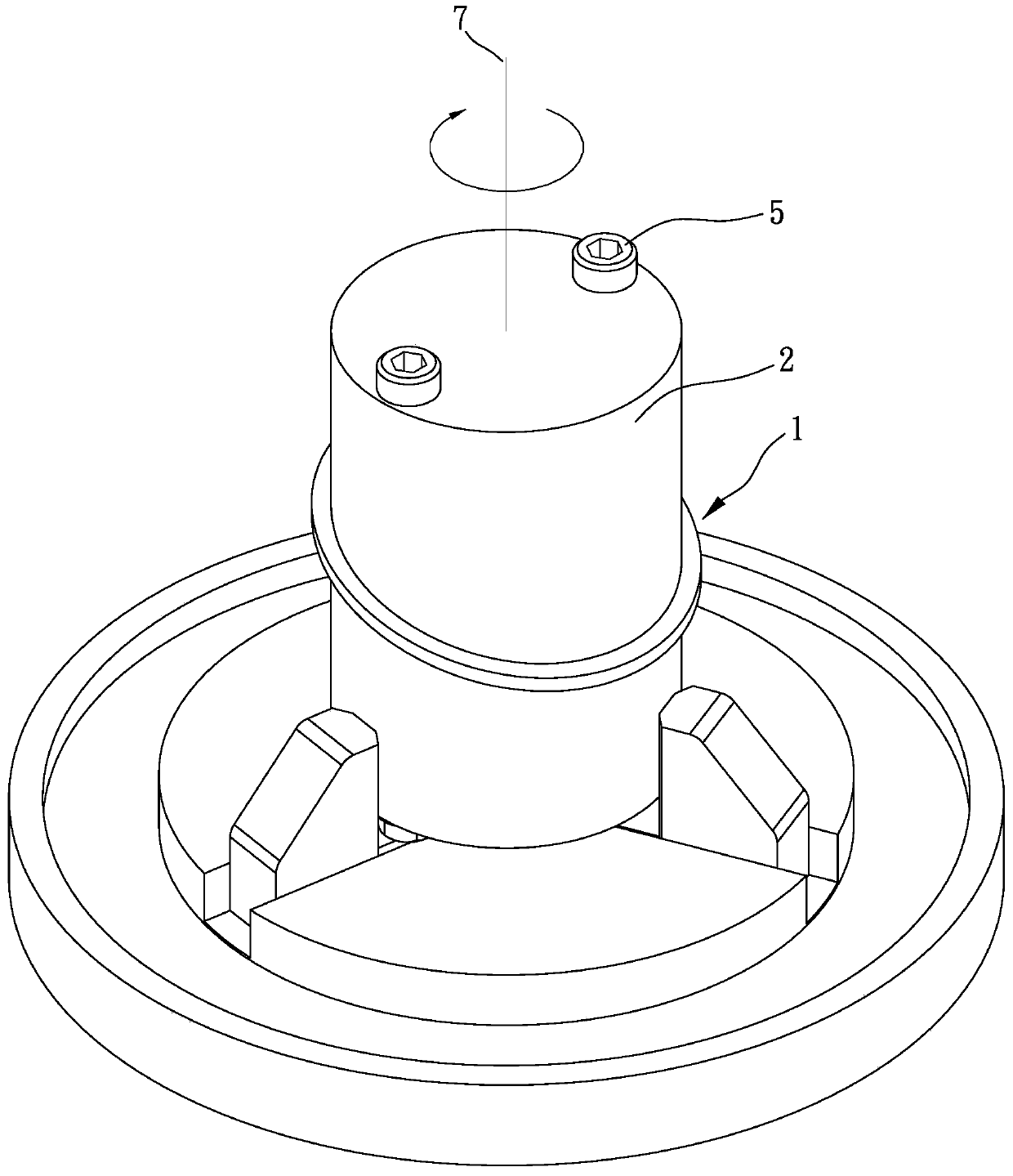

[0034] At least one piece 1 is provided, and each piece 1 has a first side 11 and a second side 12 opposite to each other in the thickness direction. The at least one piece 1 is fixed on a jig 2 . A cutting edge 31 having a transverse direction to the first side 11 of the at least one piece 1 is provided. Make the cutting edge 31 cut the at least one piece of body 1 along a closed cutting path (not shown in the figure) relative to the at least one piece of body 1. An end point 61 and a second end point 62 , and a third end point 63 and a fourth end point 64 opposite to each other. Wherein, the cutting edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com