Linear backflow defoaming filling machine

A filling machine and defoaming technology, used in packaging, bottle filling, liquid bottling, etc., can solve the problems of easy wear, short service life, and inability to effectively ensure normal production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

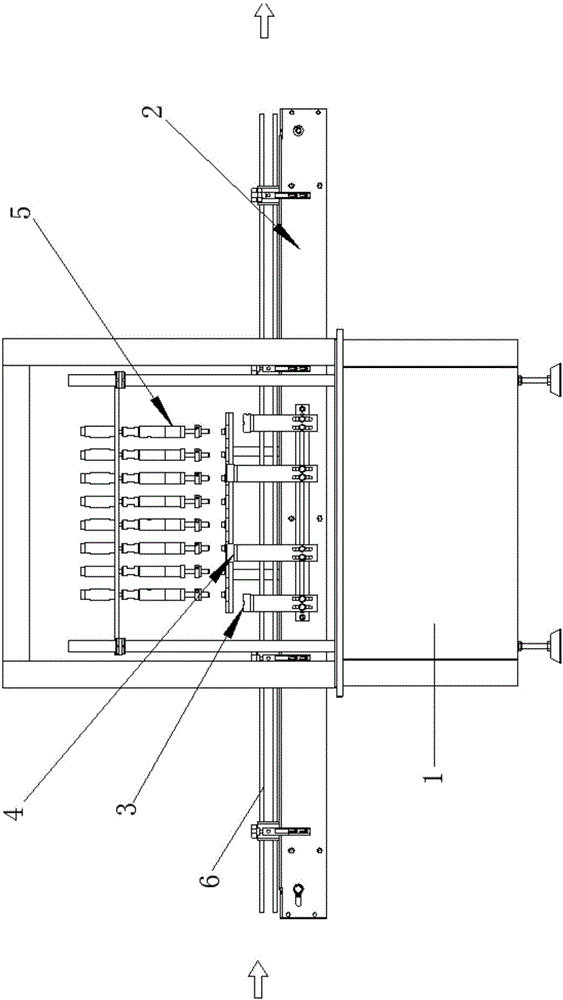

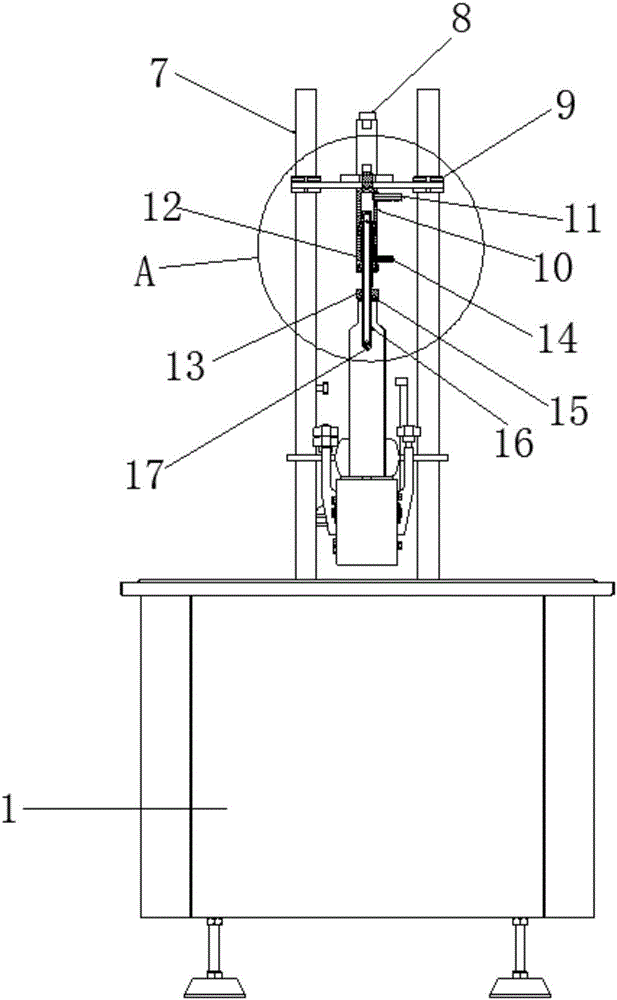

[0017] Such as figure 1 and figure 2 As shown, the linear reflux defoaming filling machine of the present invention includes a frame 1 on which a conveying part 2 is arranged, and the frame 1 is sequentially provided with a cylinder bottle dividing part 3 along the conveying direction of the conveying part 2 1. Positioning part 4 for clamping the mouth of the bottle. A backflow filling head 5 is arranged above the bottle mouth positioning part, and the backflow filling head 5 is fixed on the frame 1 .

[0018] Further, in order to obtain better protection during the conveying process of the filled bottle body, guardrails 6 are arranged on both sides of the conveying part 2 .

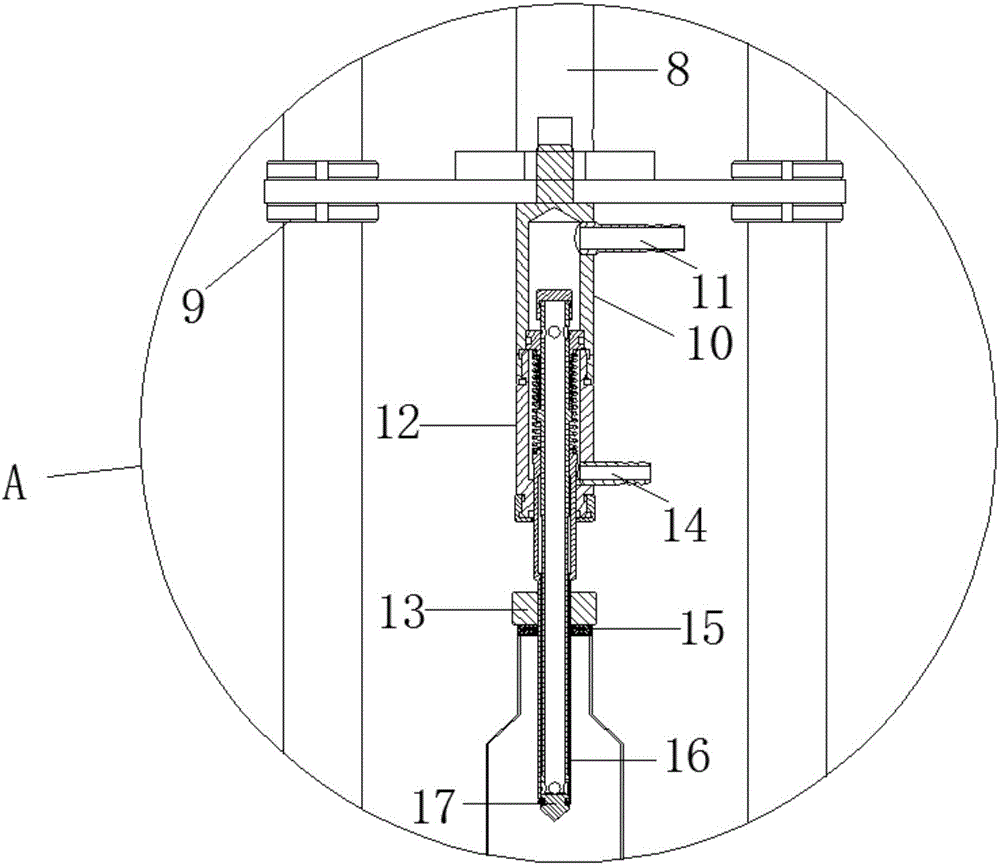

[0019] Further, such as figure 2 and image 3 As shown, the return type filling head 5 includes a filling head driving cylinder 8 arranged on a column 7 . The lower end of the filling head driving cylinder 8 is connected with the valve body 10, and the upper end of the valve body 10 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com