Diaphragm type pressure relief valve

A pressure reducing valve and diaphragm type technology, applied in the field of pressure reducing valves, can solve problems such as threats to the personal safety of staff, failure of instruments and equipment to work properly, discontinuous gas supply, etc., to reduce potential safety hazards, simple structure and tightness Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

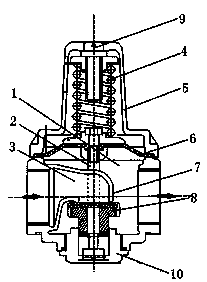

[0009] A diaphragm pressure reducing valve, the valve includes a valve body 1, a connecting rod 2, an inner cavity 3, a spring 4, a valve cover 5, a diaphragm 6, a valve seat 7, a valve core 8, an adjusting nut 9 and a base 10. The air inlet and air outlet are arranged on both sides of the valve body 1, the valve body 1 is in the shape of a round bottle, and the valve core 8 is arranged between the air inlet and the air outlet in the valve body 1 , the base 10 is set on the bottom of the valve body 1, the valve core 8 can move up and down in the base 10, the valve cover 5 is set on the upper part of the valve body 1, and the adjusting nut 9 is set on the valve body 1 top, the lower part of the adjustment nut 9 is connected to the connecting rod 2, the spring 4 is arranged on the connecting rod 2 in the valve cover 5, and the top end of the lower part of the connecting rod 2 is provided with a diaphragm 6. The diaphragm 6 moves up and down in the valve body 1 following the spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com