Aluminum foil secondary formation system and method

A chemical formation method and aluminum foil technology, applied in electrolytic capacitors, coatings, plating tanks, etc., can solve the problems of easy damage to the oxide film and system costs, and achieve the effects of reducing frequent contact, reducing costs, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

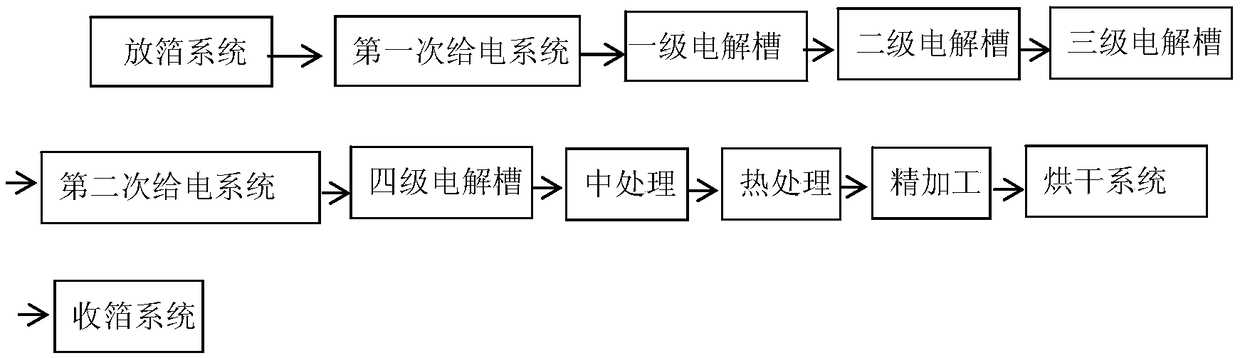

[0028] The present invention aims to provide a secondary formation system and method for aluminum foil, which solves the problems that the oxide film of aluminum foil is easily damaged and the system cost is high during the production process caused by the traditional aluminum foil formation process.

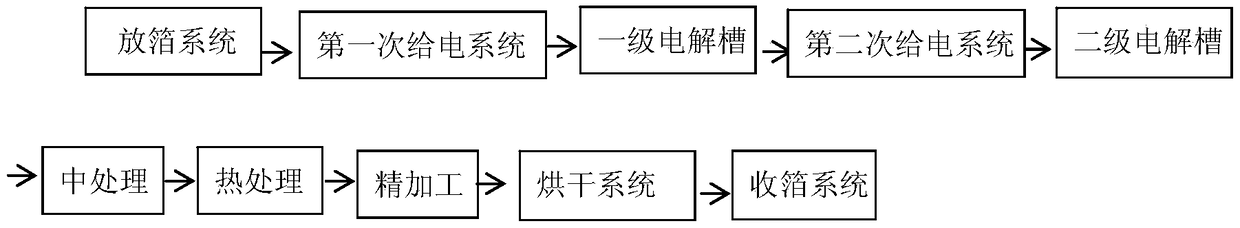

[0029] Such as figure 2 As shown, the secondary formation system of aluminum foil in the present invention is composed of a sequentially connected foil releasing system, the first power supply system, the first-level electrolyzer, the second power supply system, the second-level electrolyzer, the intermediate treatment system, It is composed of heat treatment system, finishing system, drying system and foil receiving system; the actual plane length of the first-level electrolytic cell is 1.5m, and the second-level electrolytic cell includes 4 tank bodies, the actual plane lengths are respectively 0.8m, 1.5m, 1.2m, 0.8m. It can be seen that the actual plane length of the primar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com