On-line measurement method and measurement device for residual stress of conductive thin film material

A residual stress, conductive film technology, used in measuring devices, force/torque/work measuring instruments, and using stable tension/pressure to test the strength of materials, etc., to simplify the measurement process, high measurement efficiency, and ensure real-time effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

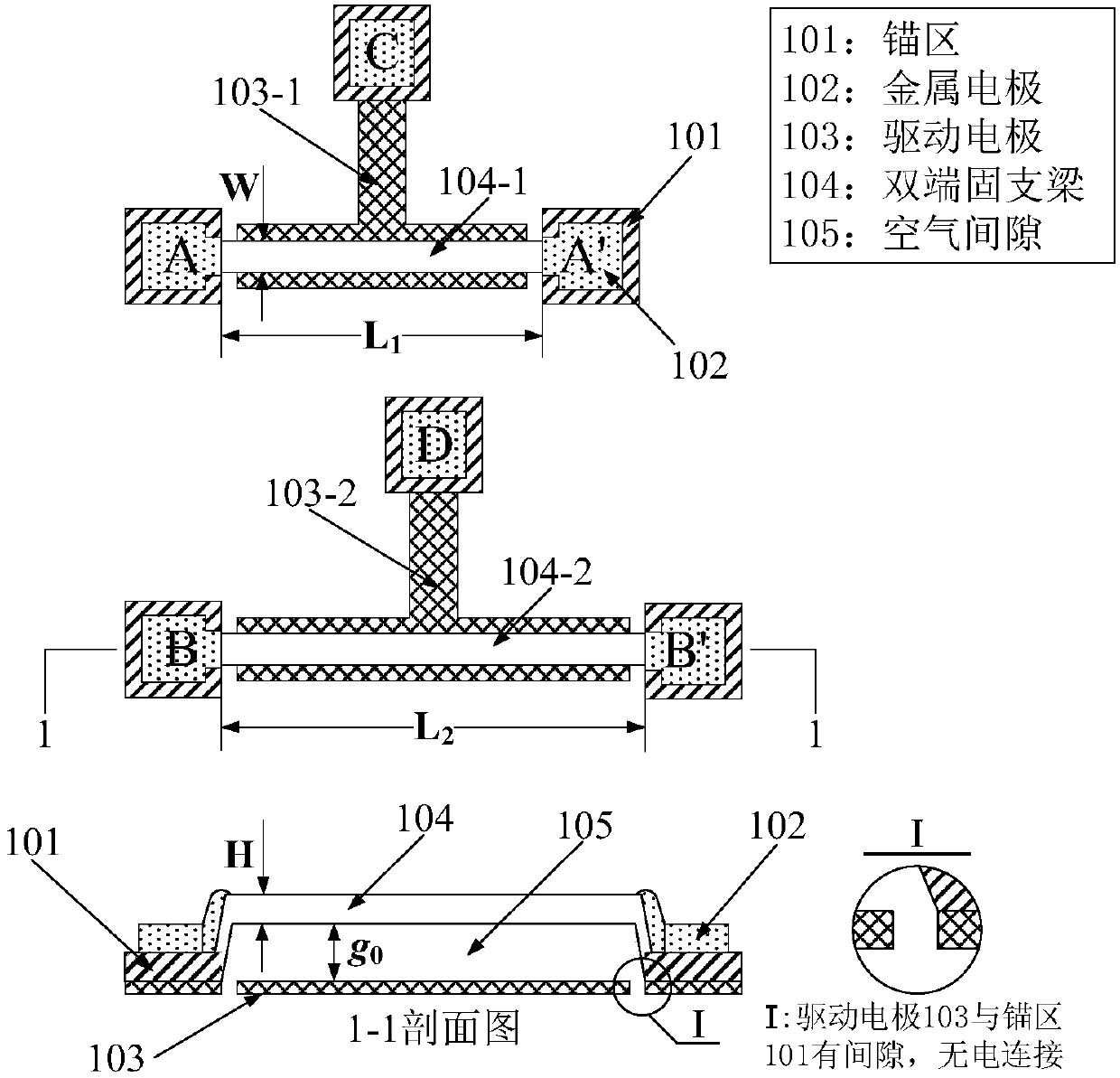

[0040] figure 1 It is a schematic diagram of the structure of the measurement device of the present invention, which is composed of two double-end fixed beam measurement units made of polysilicon material, which are respectively the first measurement unit and the second measurement structure unit; the first measurement unit consists of The first driving electrode 103-1, the first measuring piece 104-1, and three anchor regions are composed of three anchor regions. Metal electrodes are respectively set on the three anchor regions. Here, the three anchor regions are respectively marked as C, A, and A' ; The first drive electrode 103-1 is T-shaped, and the three ancho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com