Two-dimensional motion slamming test device

A test device and two-dimensional motion technology, applied in the direction of fluid dynamics test, measuring device, machine/structural component test, etc., can solve problems that cannot meet the designer's requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

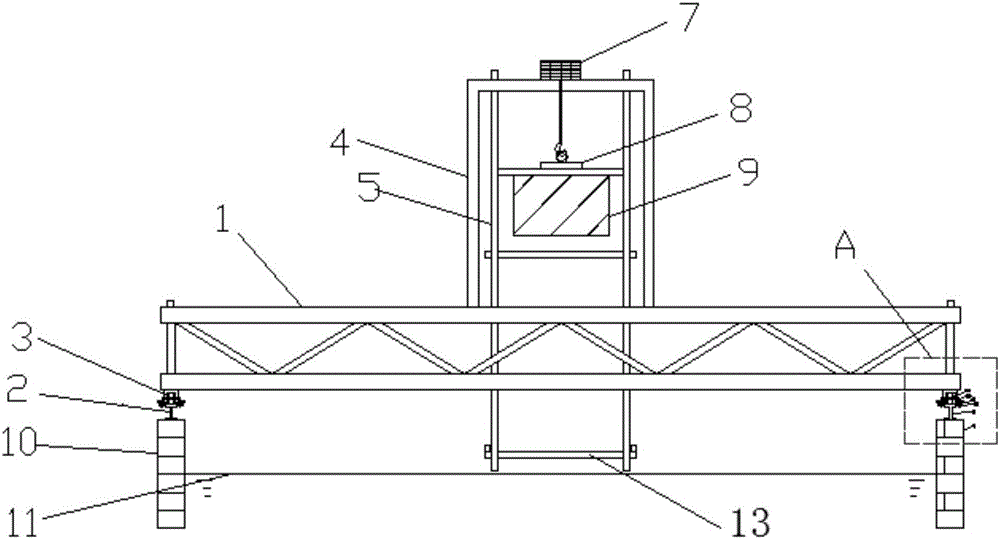

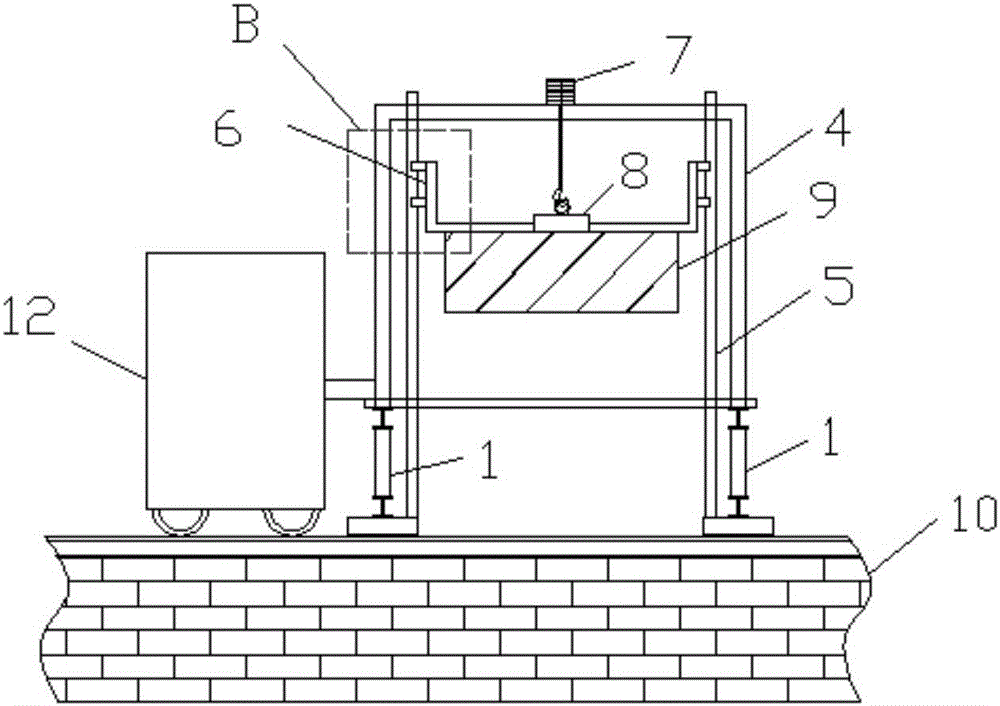

[0022] combine figure 1 and figure 2 , The two-dimensional motion slamming test device of the present invention is mainly composed of three parts: a moving bracket, a sliding module and a lifting module. The mobile bracket is composed of a truss structure 1 across the pool and rolling wheels 3 running along the track 2 of the drag pool. The sliding module consists of a steel outer frame 4, stainless steel rails 5 and connecting members 6 that can slide on the rails. Lifting module is made up of electric hoist 7 and electromagnet 8. There is an adjustment gap between the outer frame and the steel rail.

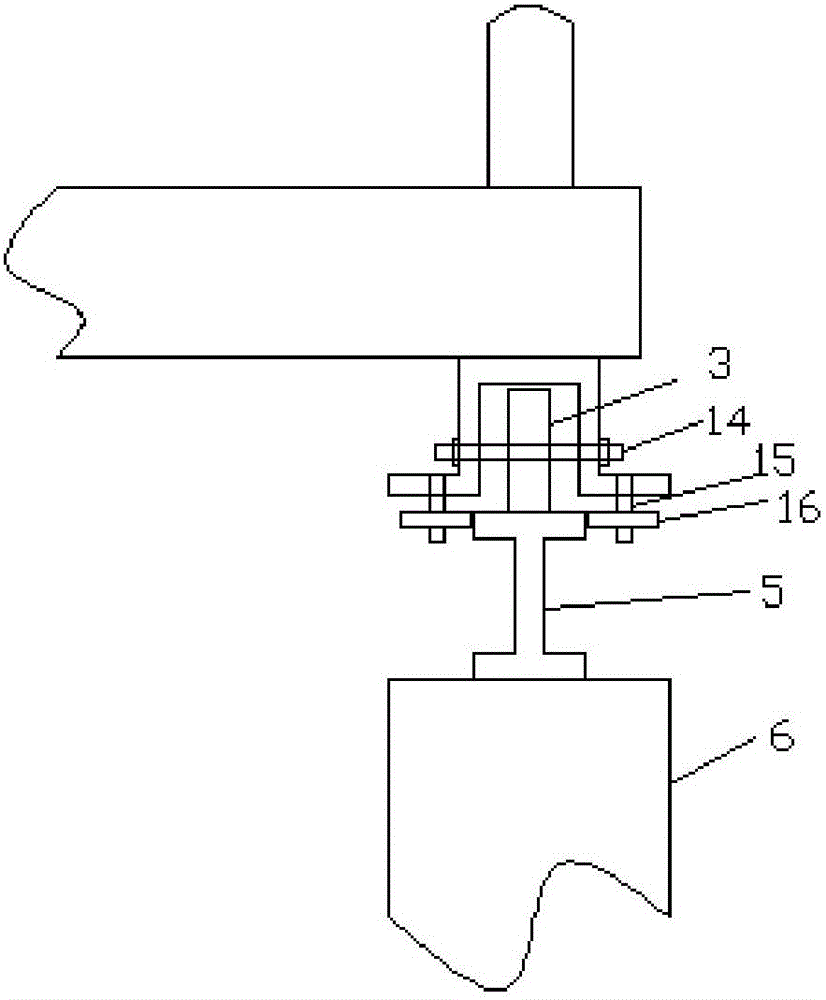

[0023] Simultaneously combine image 3 and Figure 4 , the scroll wheel is installed on the lower end of the mobile bracket by the shaft and the bearing 14, and the first guide wheel 16 is set by the guide wheel shaft and the bearing 15 on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com