Stress safety inspection scheme for center diaphragm structure of shallow-buried ultra-large-span tunnel

A technology of safety and structural internal force, which is applied in the field of force safety inspection scheme of partition wall structure in shallow-buried super-long-span tunnels, and can solve the problem of simplified, rough, unconsidered deformation coordination of steel frame of side wall and middle partition at the arch foot of steel frame Displacement and other problems, to achieve the effect of reducing project cost, ensuring safety and stability, and ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] In order to make the objects and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and engineering examples. It should be understood that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

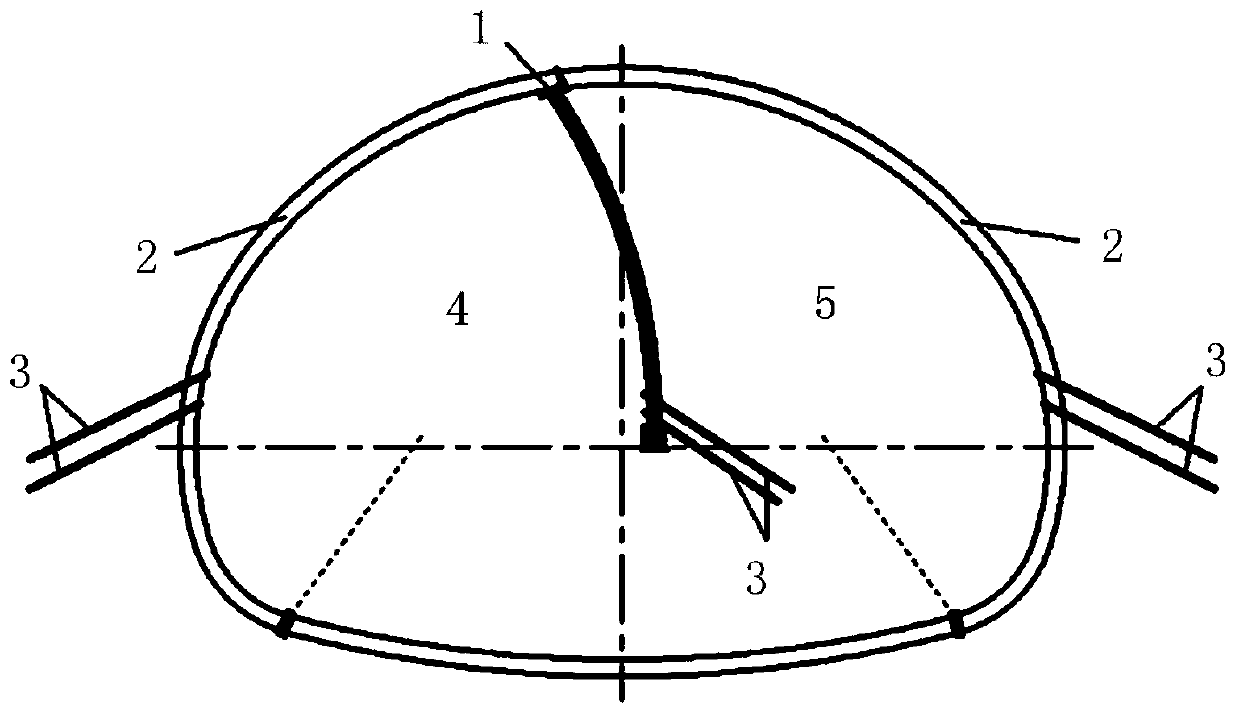

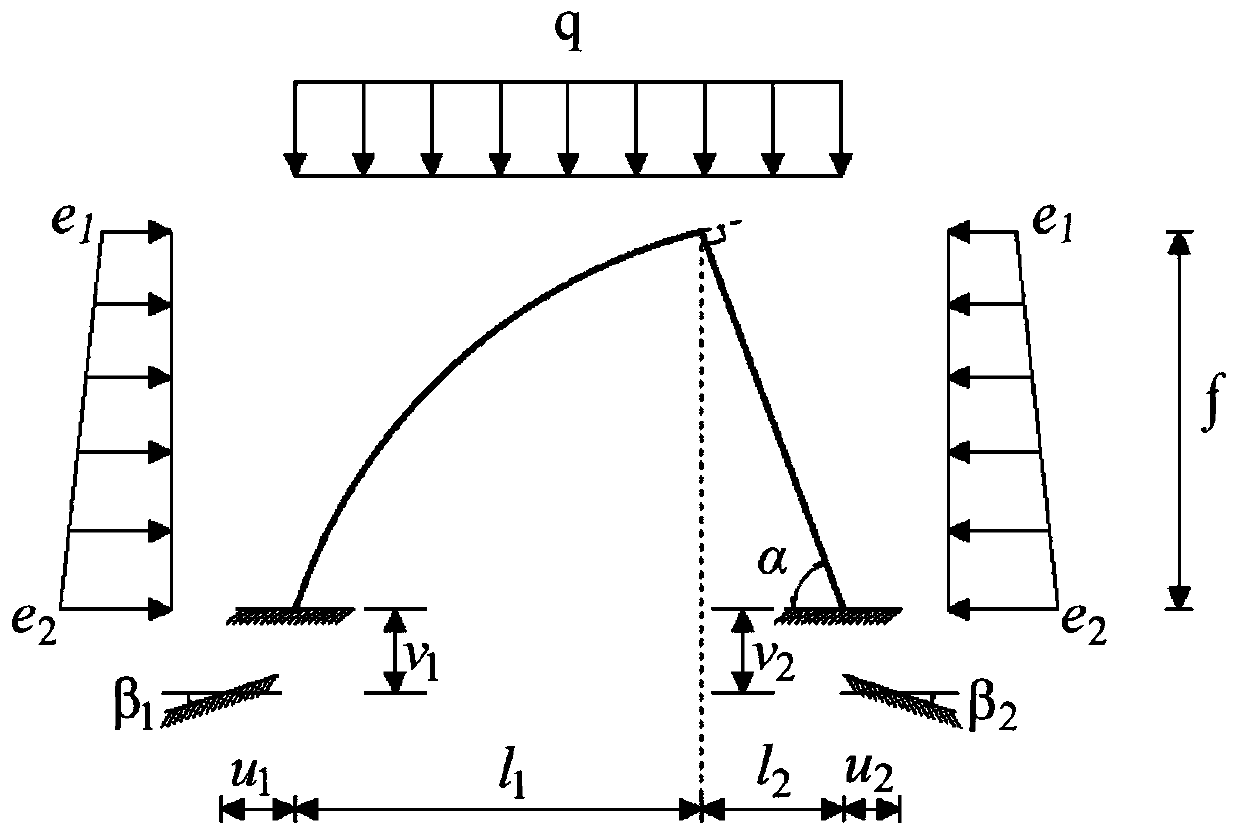

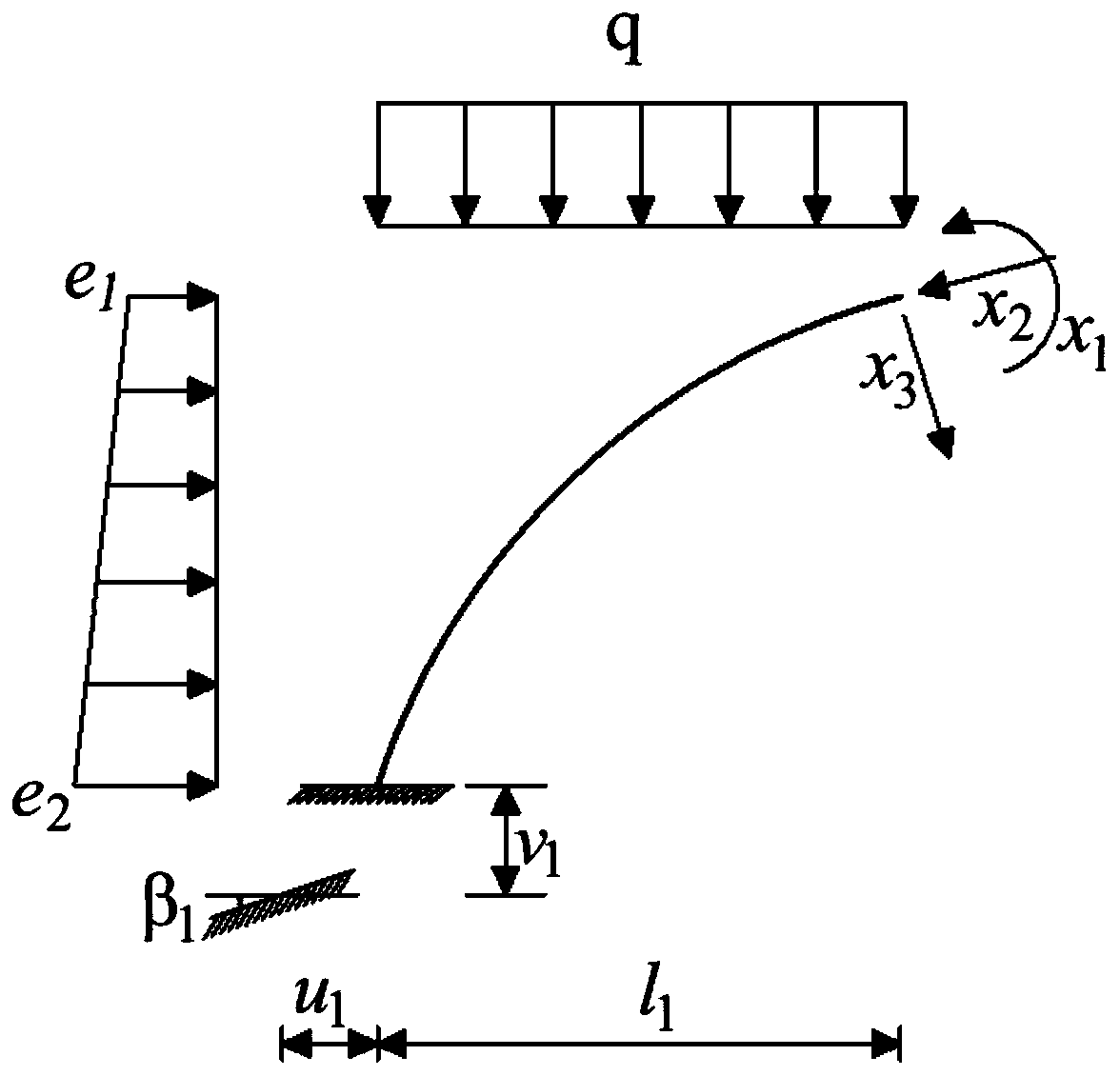

[0077] figure 1 The construction plane structure of the ultra-long-span tunnel is given, and the left and right sides of the middle partition 1 are the leading upper step 4 and the rear leading upper step 5 respectively; figure 2 The overall model diagram of the support structure of the leading upper step is given. After the excavation of the leading step of the tunnel, the initial support is applied and the steel frame of the middle partition is erected. The steel frame 2 of the side wall is rigidly connected with the middle partition 1 at the vault, and at the same time, the bottom of the steel frame is firm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com