Paint mixing performance testing device

A mixing performance and testing device technology, applied in the direction of measuring devices, mixers, mixers with rotating containers, etc., can solve the problems of damage to the physical properties of coatings, high investment costs, high speed, etc., and achieve low cost, low speed, and convenience The effect of physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

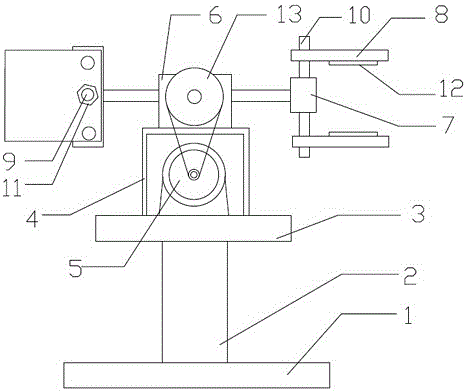

[0016] Embodiment 1: as figure 1 The paint mixing performance test device shown includes a support 1, which is provided with a vertically upward support column 2, and the top of the support column 2 is fixed and screwed to a support platform 3, and the top surface of the support platform 3 is formed with a horizontal The cross-section is an inverted bracket 4, the top surface of the support platform 3 is located in the bracket 4, and the motor 5 with the output shaft horizontally arranged is fixed and screwed. The top of the bracket 4 is also fixed with a gear box 6, and the output shaft of the motor 5 drives the gear. The gear in the case 6 rotates, and the output shaft of the gear case 6 is also fixed with a paint tank holding device.

[0017] Gear box 6 is a T-shaped 90-degree steering gear box.

[0018] The gear box 6 has 1 input shaft and 2 output shafts in total. The output shaft and the input shaft of the gear box 6 are arranged horizontally, and the angle between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com