Inner taper pipe type wind instrument

A technology of wind instruments and cone pipes, which is applied to musical instruments, wind instruments, instruments, etc., can solve the problems of high price, difficulty in learning, and high strength required for performance, and achieve penetrating power, large range, and easy performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

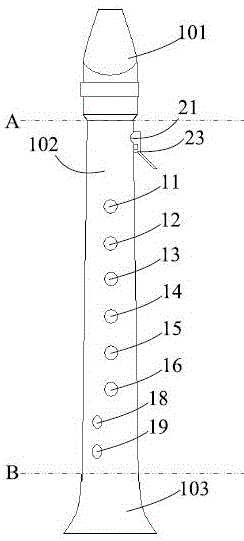

[0025] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0026] figure 1 with 2 It is a schematic front view and a rear view of a pipe body of a vertical wind instrument in the prior art. The wind instrument is typically a traditional Chinese national musical instrument, for example, flute, clarinet, cucurbit silk and the like. In order to avoid obscuring the present invention, some other details of the wind instrument, such as blowholes, etc., are not described, and these details vary from instrument to instrument. For example, different wind instruments may have different shapes or positions of the blowholes. But when figure 1 with 2 The wind instruments shown do not have mouthpieces, reeds and other parts.

[0027] Such as figure 1 As shown, the wind instrument has a pipe body 10, and several sound ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com