Motor stator coil and in-wire embedding slot insulation paper shaping device

A motor stator and shaping device technology, which is applied in electromechanical devices, laying solid insulation, manufacturing motor generators, etc., can solve the problems that the coils outside the hole cannot be fully integrated and cannot be obtained, and achieve a large creepage distance and a large The effect of dilation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

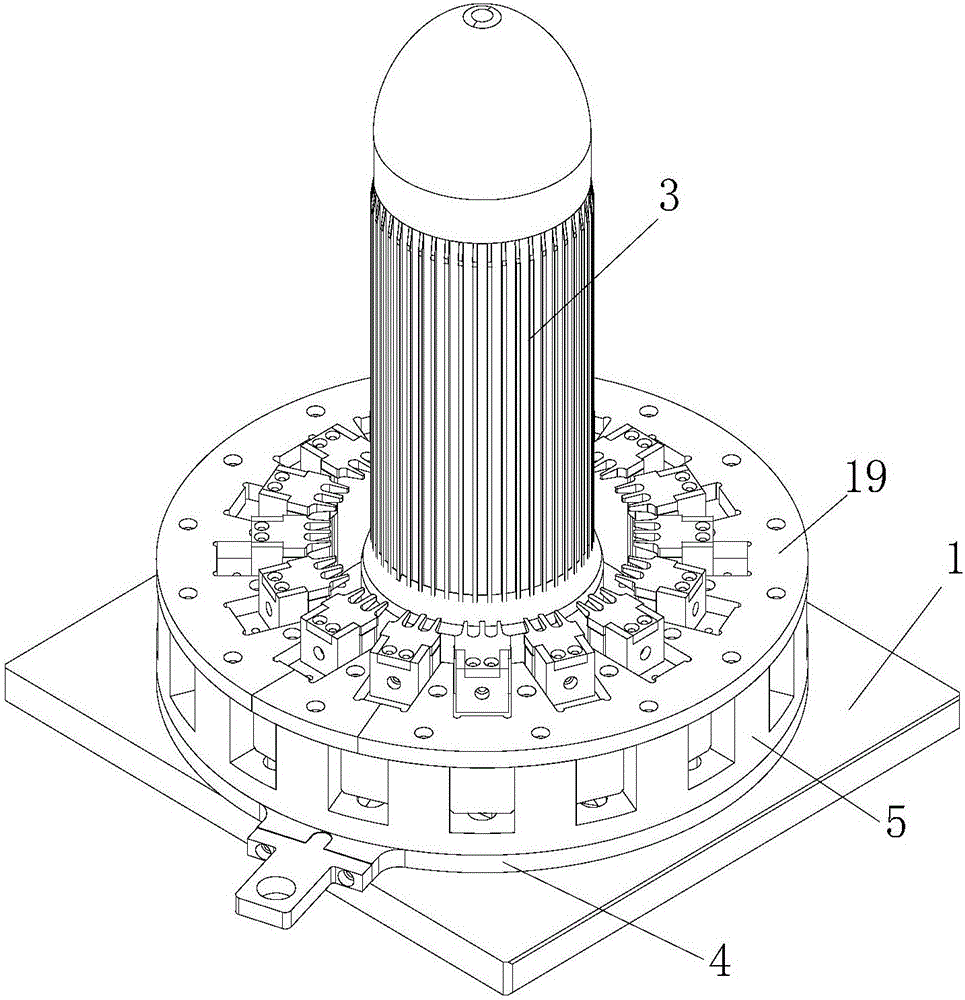

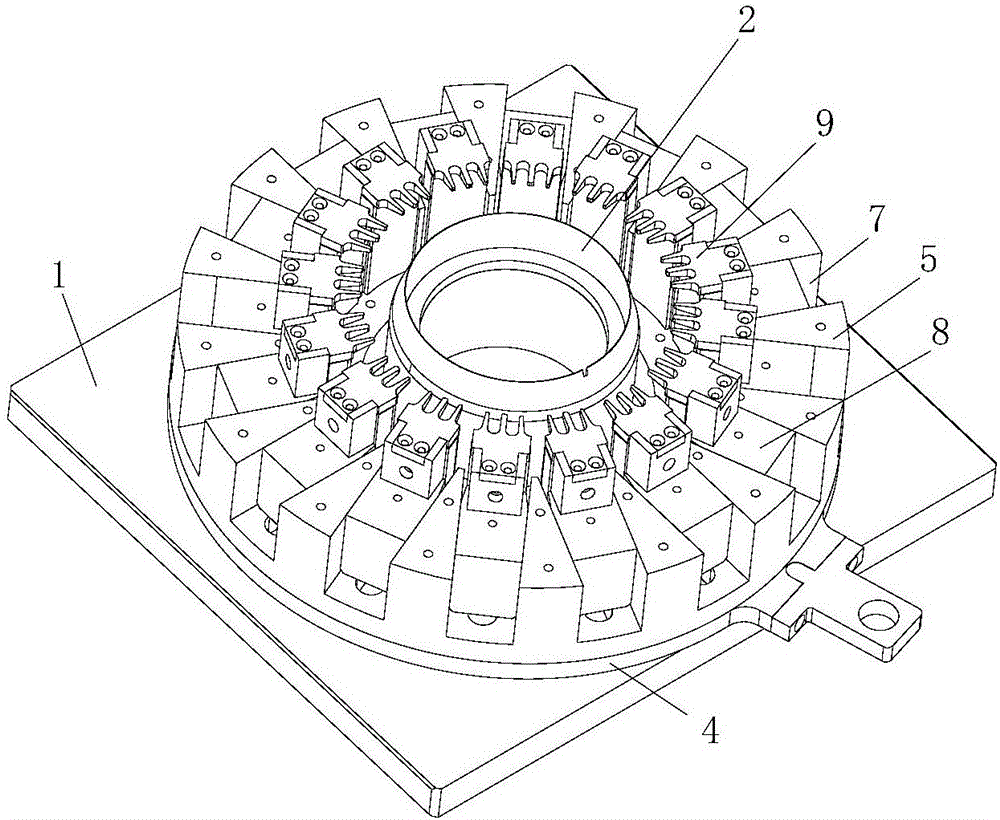

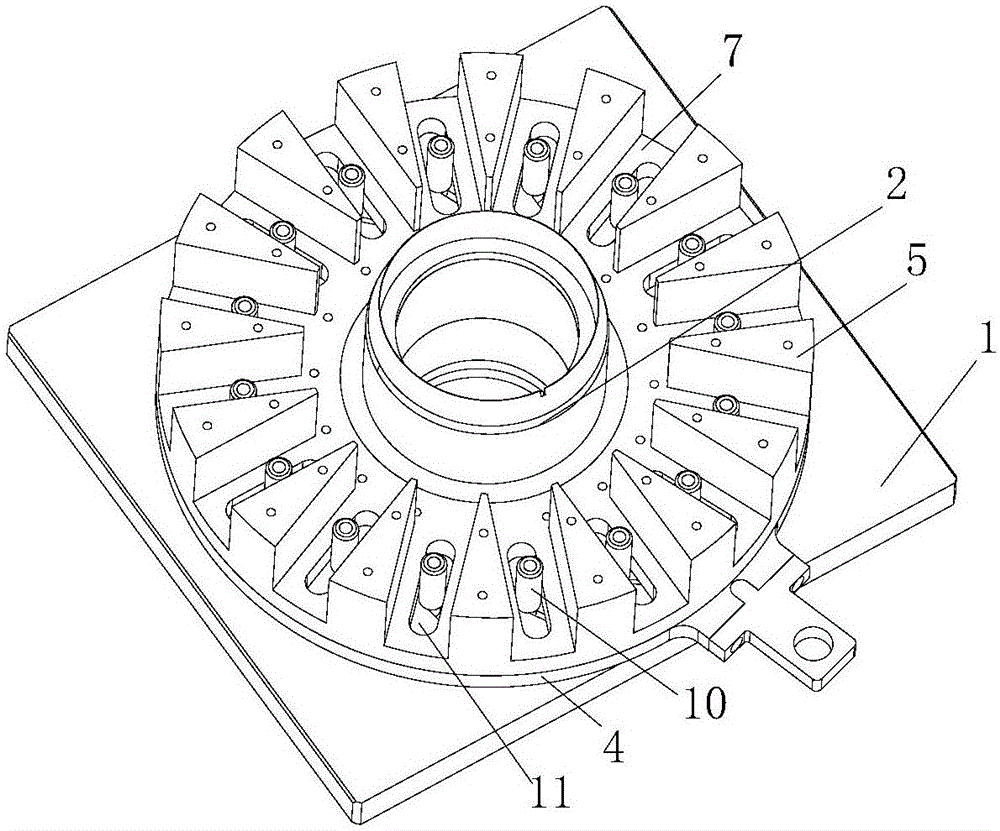

[0047] Such as Figures 8 to 10 as well as Figure 24 As shown, the first out-of-hole coil shaping device 100 in the present invention includes a base 101 and a compression device arranged on the base 100 and compressing radially along the base. Both the base 101 and the compression device are provided with a A hole for the expansion device 200 to pass through. The base 101 is a rectangular parallelepiped plate-shaped part, which mainly supports the compression device. Described compression device comprises the slide block seat 102 that has through hole, slide block 103, briquetting block, slide block driving mechanism, slide block seat 102 is disk shape, and one end of slide block seat 102 is fixedly connected with base, and slide block seat The other end of 102 is provided with a plurality of grooves 102a arranged at intervals along the radial direction of the slider seat. In this embodiment, the number of grooves 102a is 36, and these grooves 102a are evenly distributed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com