Glass material for press molding, method of manufacturing glass material for press molding and method of manufacturing optical element

A technology of press molding and manufacturing method, applied in optical components, glass manufacturing equipment, optics, etc., can solve problems such as poor optical components, and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

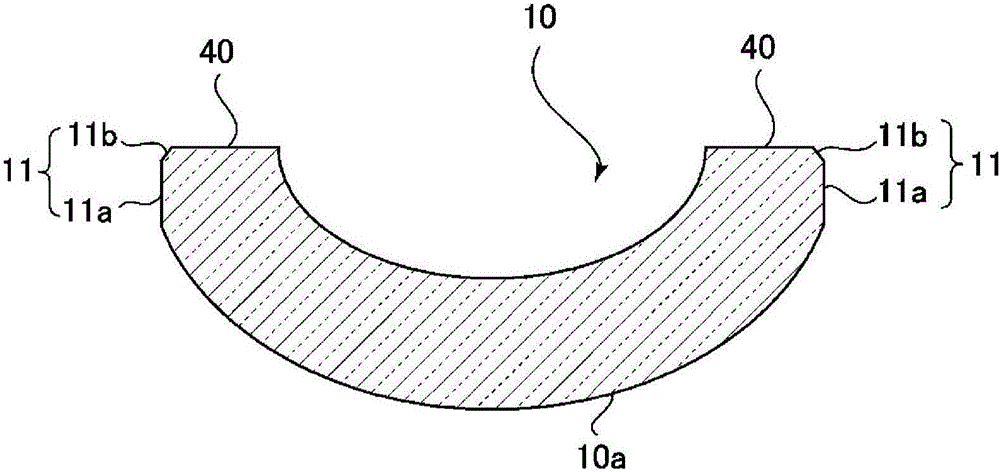

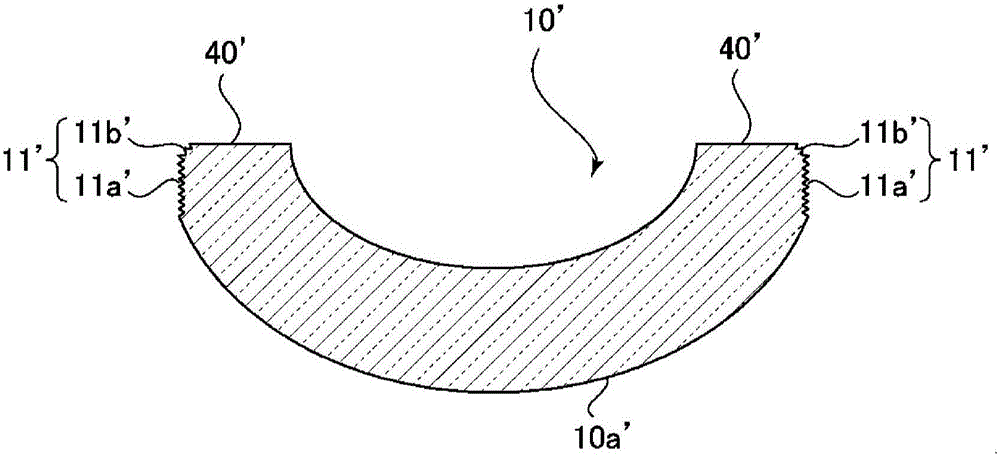

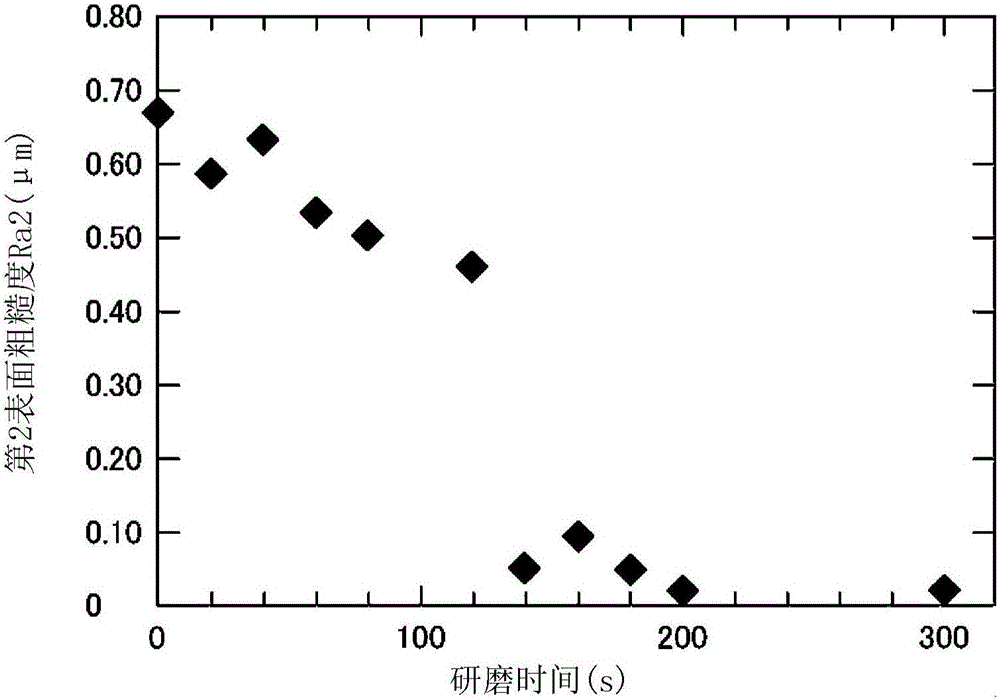

[0030] Below, while referring to the attached Figure 1 One embodiment of the glass blank for press molding, the manufacturing method of the glass blank for press molding, and the manufacturing method of an optical element of this invention is demonstrated in detail.

[0031] In this specification, the "glass blank for press molding" mainly refers to a glass blank used for press molding, and refers to a cold preform. The cold preform refers to a preform formed by cold working such as centering. In addition, the "glass blank material for press molding" refers to a cold preform in the previous stage for forming the "glass blank for press molding" in this specification, and particularly refers to a cold preform that has been centered and has a frosted side end surface. moldings. In addition, the side end surface of the "glass material for press molding" is flatter than the frosted one, but from the viewpoint of ensuring the shape accuracy of the optical element after press mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com