Shoe upper and necking shaping method of shoe upper

A shoe upper and necking technology, which is applied to shoe lasts, footwear, applications, etc., can solve the problems of difficult control of tension, high labor intensity, and high technical requirements for workers, and achieve moderate and average tension, convenient operation, and high quality. consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

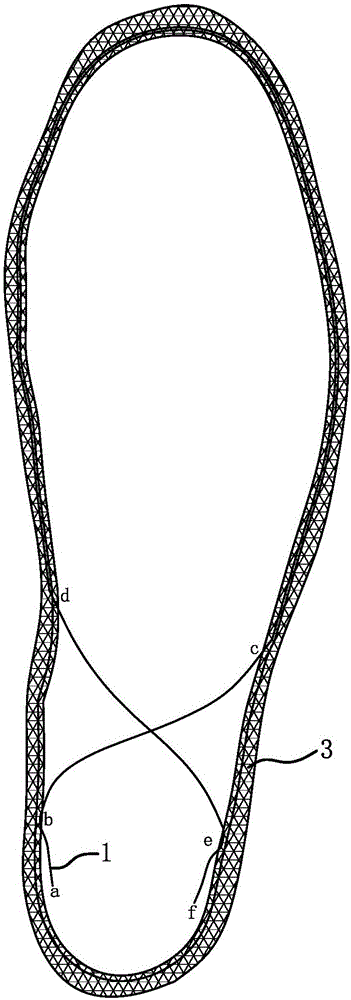

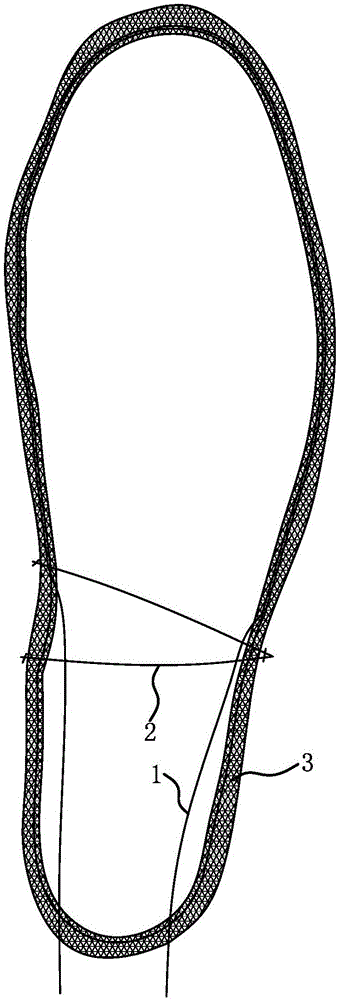

[0016] Such as figure 1 As shown, a shoe upper includes a shoe upper and a last line 1 . The bottom edge of the upper includes the front bottom edge, mid-waist inner bottom edge, mid-waist outer bottom edge and rear bottom edge; the part of the bottom of the upper that needs to be concave inward is called the mid-waist.

[0017] The bottom edge of the vamp is sewn with a plurality of wire loops 3 arranged along the bottom edge line, and the wire loops 3 are indicated by broken lines in the drawings.

[0018] The backing line 1 is arranged along the bottom edge line of the shoe upper and the backing line 1 is located in the backing ring 3. Two sections of the backing line 1 are arranged in the backing ring 3 at the bottom edge of the front part. One end of the backing line 1 is from the front The other end of the side line 1 passes between the bottom edge of the front part and the outer bottom edge of the middle waist. The two ends of the backing line 1 are intersected, and ...

Embodiment 2

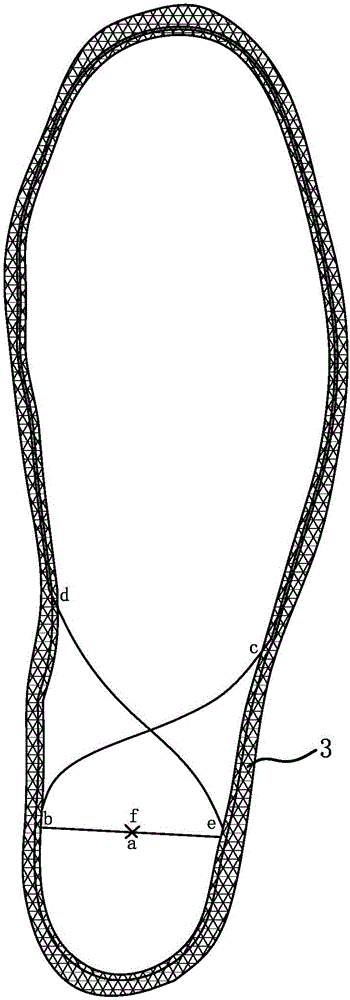

[0021] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be redundantly described, and only the differences will be described, and the differences are as follows: figure 2 As shown, the upper side thread 1 is a nylon thread, pull the upper side line 1 to the design tension value (such as 800N), and then tie the two ends of the upper side line together to avoid rebound and reset, so as to realize that the upper waist of the shoe is really tightened and The tension is moderate and average.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com