Automatic color steel plate perforating production line

A color steel plate and production line technology, applied in maintenance and safety accessories, feeding devices, positioning devices, etc., can solve the problems of unguaranteed quality and accuracy, damage, and inability to meet the needs of mass production, and achieve quality and accuracy. Guarantee and reduce the effect of artificial injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

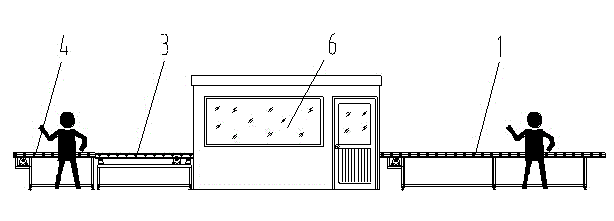

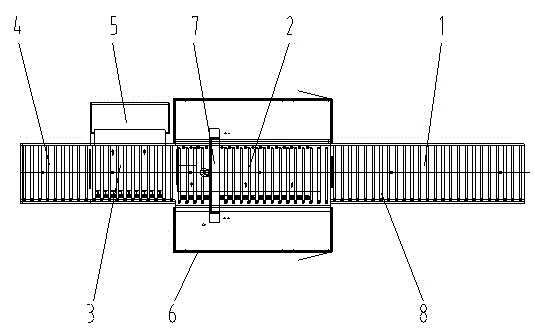

[0012] The present invention will be further described below in conjunction with the accompanying drawings. An automatic drilling production line for color steel plates includes the following equipment: a plate upper line section 1, which is used to horizontally place the color steel plate on the upper line segment of the plate, and prepares for the hole opening of the color steel plate; a plate processing area 2, which is used for processing the surface of the color steel plate Hole and waste sending section 3, send out the waste produced by the color steel plate after hole opening, plate lower line section 4, remove the processed color steel plate to complete the processing operation, waste car 5, used for transportation of waste generated, and protection room 6. To prevent flying debris generated during the processing from hurting people, the upper line section 1 of the plate, the processing area 2 of the plate, the waste delivery section 3, and the lower line section 4 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com