Easy-dismounting type two-step ejection mechanism

A technology of secondary ejection and easy disassembly and assembly, which is applied in the field of molds, can solve the problems of product breaking and straining, no starting force, and small ejection force, and achieve the effects of short processing and assembly cycle, low manufacturing cost and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

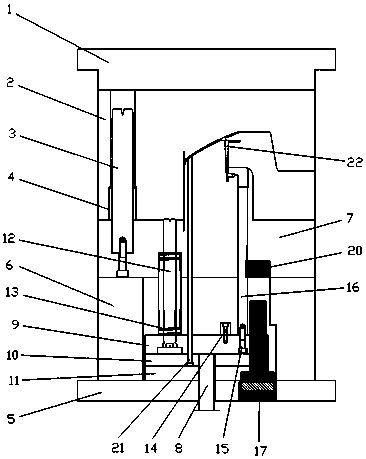

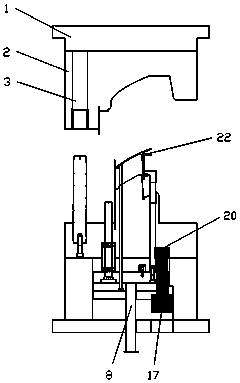

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] The embodiment of the present invention provides an easy-to-disassemble secondary ejection mechanism, which is applied in a mold, and the mold includes an upper cover plate 1, a fixed platen 2 connected to the upper cover plate 1, and a guide post connected to the fixed platen 2 3. The guide sleeve 4 set on the guide post 3, the bottom plate 5 matched with the upper cover plate 1, the mold foot 6 set on the bottom plate 5, the movable template 7 set on the mold foot 6;

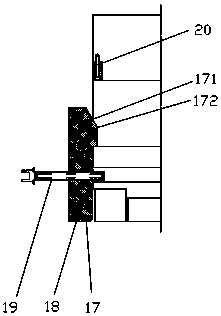

[0017] see Figure 1 to Figure 5 , the easily removable secondary ejection mechanism includes a plastic press rod 8 arranged on the bottom plate 5, an upper top board 9 connected with the plastic press rod 8, a middle top board 10 and a lower top board arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com