Spring piece and mesh loading process equipment

A shrapnel and material feeding technology, applied in the direction of coating, etc., can solve the problems of low production stability, difficult disassembly and assembly, easy damage of shrapnel, etc., and achieve the effect of simple tooling structure, high production stability, and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

[0032] The orientations involved in this manual are all based on the orientations of the shrapnel and mesh feeding tooling of the present invention when they are in normal operation, and do not limit their orientations during storage and transportation. They only represent relative positional relationships, not absolute positional relationships.

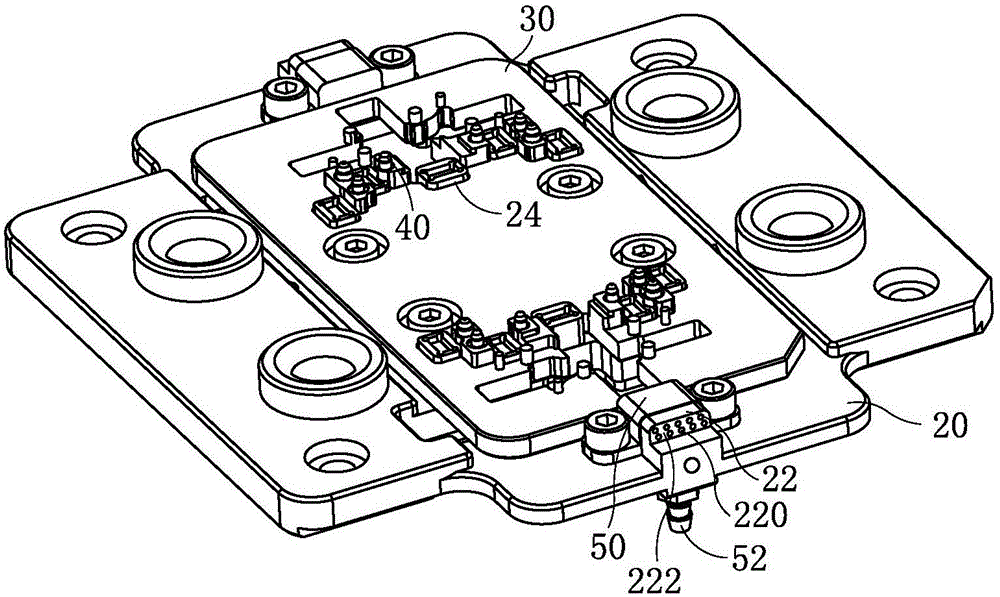

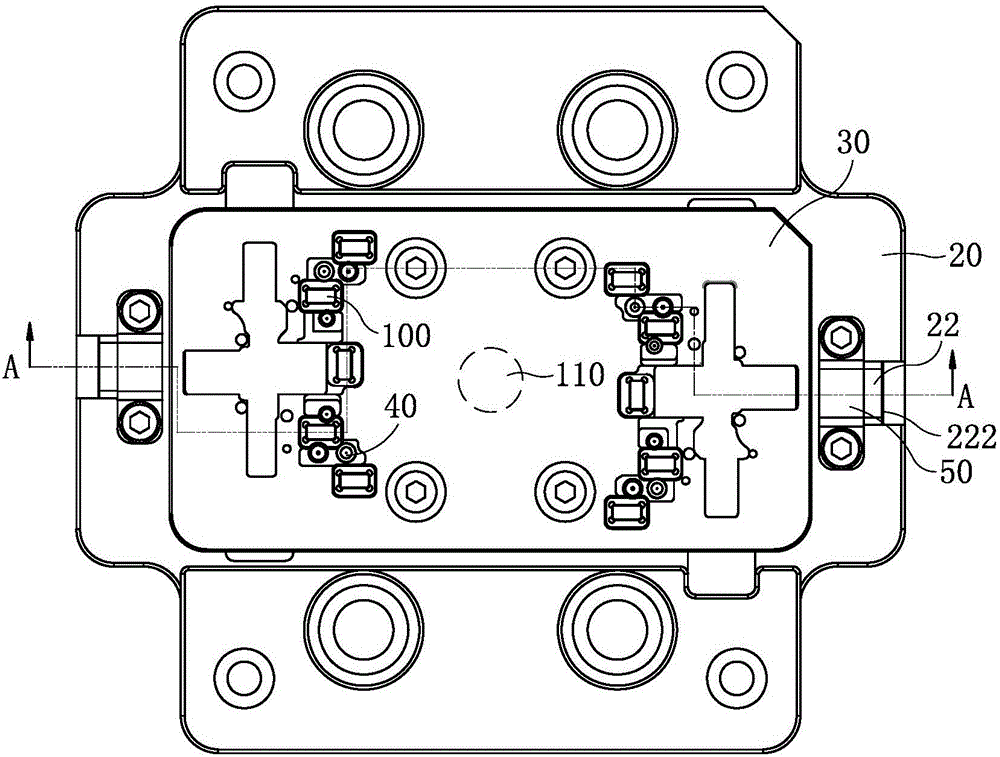

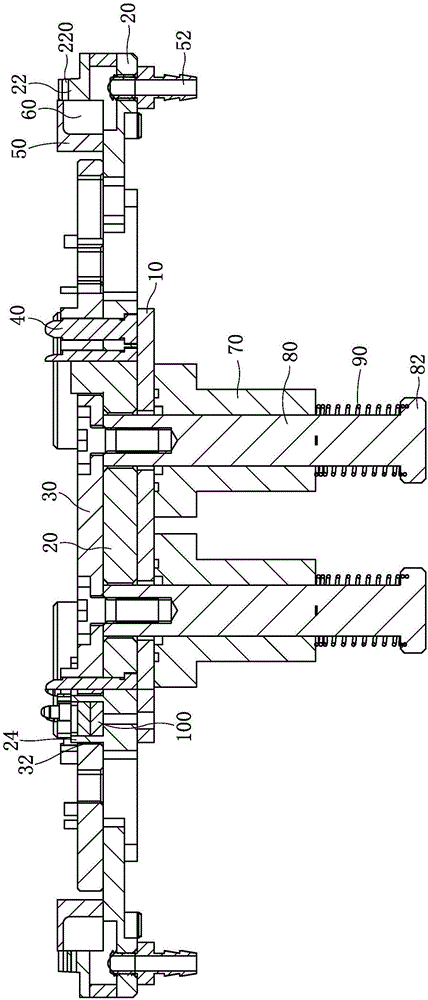

[0033] Such as figure 1 , figure 2 and image 3 As shown together, a spring and mesh feeding tooling includes a base plate 20, a plurality of spring positioning pins 40 are vertically fixed on the base plate 20, and a large hole is provided on the base plate 20 corresponding to each spring positioning pin 40. Countersunk hole, the lower end of the shrapnel positioning pin 40 is provided with a convex cap, the convex cap is located in the large hole of the countersink hole, and the lower end surface of the shrapnel posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com