Bronzing plate installation method

A bronzing plate and gold-loading plate technology, applied in the field of bronzing plate-loading, can solve the problems of invisibility of the plate-loading process, increase in time spent, hinder production efficiency, etc., achieve intuitive plate-loading operation, reduce the difficulty of plate-loading operation, The effect of improving accuracy and plate-loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to illustrate the technical solution of the present invention more clearly, the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Obviously, the following descriptions are only some embodiments of the present invention. In other words, other embodiments can also be obtained according to these embodiments without paying creative efforts.

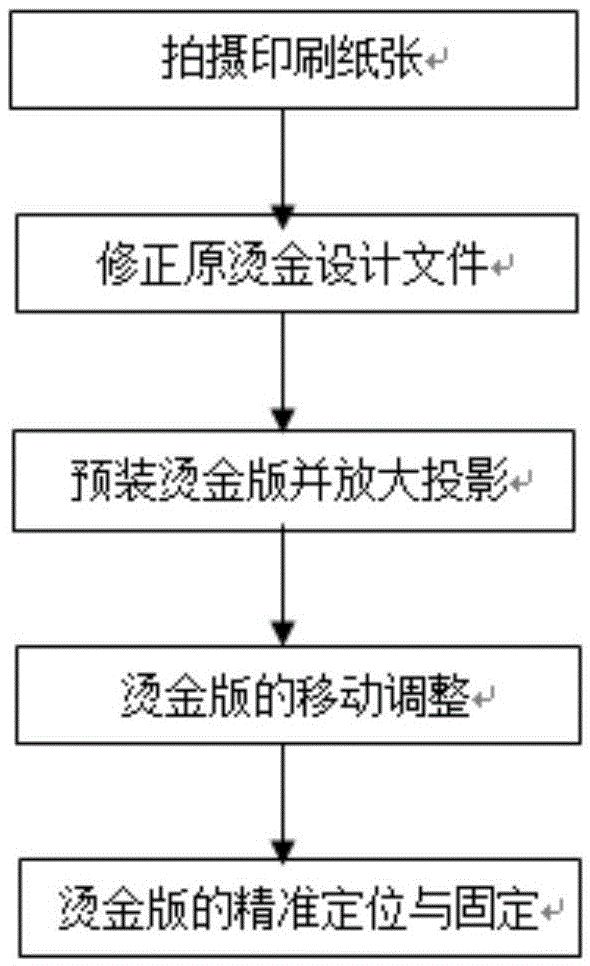

[0018] refer to figure 1 , this embodiment takes the positioning and installation of the quadruple bronzing plate as an example for specific description. A hot stamping plate mounting method, comprising the following steps:

[0019] (1) Push the honeycomb plate that needs to be installed with the hot stamping plate into the plate loading platform, and lock the honeycomb plate on the plate loading platform through the same operation method as locking the honeycomb plate on the hot stamping machine. Place and fix the printing pap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com