Rail wheel locking clamp

A track lock and locking lever technology, which is applied in the field of rail transit, can solve problems such as short service life, inconvenient operation, and easy loss of the track, and achieve the effects of long service life, elimination of potential safety hazards, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

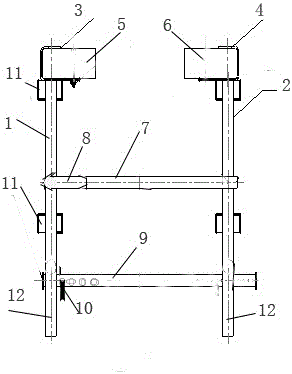

[0019] Such as figure 1 As shown, the present invention includes a first operating rod 1, a second operating rod 2, a first stop block 3, a second stop block 4, a first skid 5, a second skid 6, a connecting rod 7, and a lock 10. .

[0020] The first skid 5 and the second skid 6 are respectively embedded in the first stop block 3 and the second stop block 4 and fastened by bolts. In order to match the shape of the wheels for better locking, the opposite surfaces of the two skids are inclined surfaces, which are inclined from the outside to the inside of the track lock wheel clamp (it should be understood that the outside here refers to the first Operation lever 1, the outside of the side where the second operation lever 2 is located). In the locked state, the wheel is stuck between the two inclined surfaces and cannot move.

[0021] Preferably, the first skid 5 and the second skid 6 are in the shape of a right-angled triangle and are embedded in the corresponding stop blocks. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com