Hand press type liquid working medium filling pot

A working medium and hand-pressed technology, which is applied to liquid distribution, transportation or transfer devices, packaging, distribution devices, etc., can solve problems such as troublesome filling methods, affecting heat conduction efficiency, wasting media, etc., and achieves simple design principles and low cost. Inexpensive, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

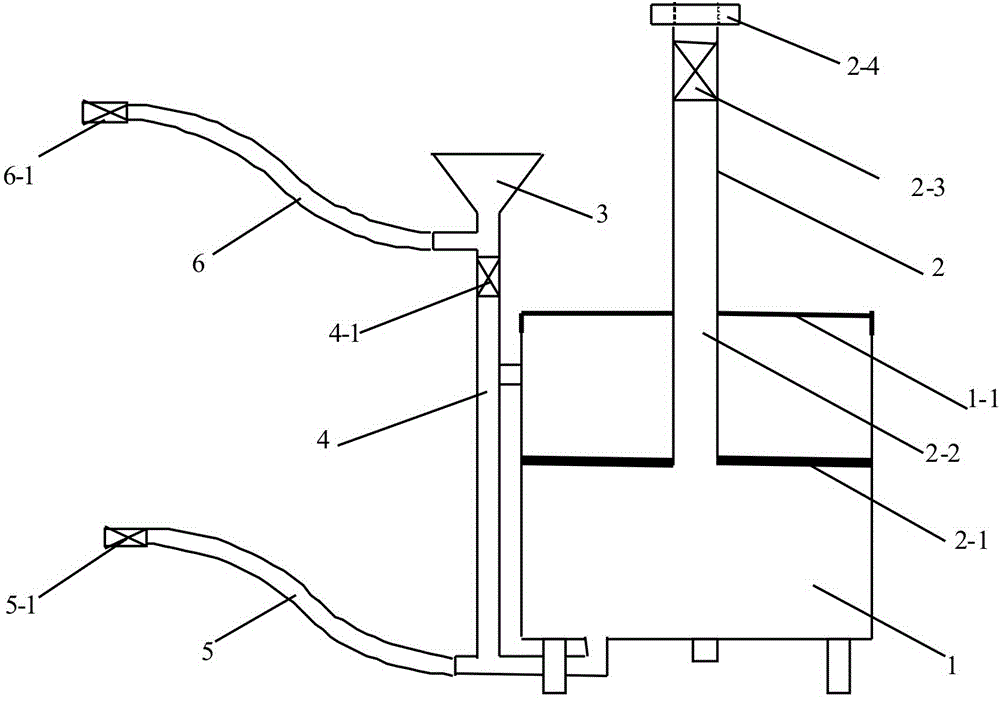

[0020] Such as figure 1 As shown, a hand-pressed liquid working medium filling pot includes six parts including a pot body 1, a hand-pressed piston 2, a funnel 3, a connecting pipe 4, a first hose 5, and a second hose 6.

[0021] The kettle body 1 is a cylinder-shaped container, the top of the kettle body 1 is equipped with a kettle cover 1-1, and the kettle cover 1-1 and the kettle body 1 are butted through a screw thread mouth. Hand-pressed piston 2 is housed in the pot body 1, and hand-pressed piston 2 is divided into: piston head 2-1, piston rod 2-2, exhaust valve 2-3, piston handle 2-4 four parts. Piston head 2-1 is cylinder hollow tubular, and rubber sealing gasket is equipped with on the outer edge, and the inner wall seal of jug body 1 coincides. The hollow tubular part of the piston head 2-1 is connected with the lower end of the piston rod 2-2. The inside of the piston rod 2-2 is hollow tubular, and its outer surface is provided with scale lines showing the inner v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com