An improved ceramic rod for the lower wheel of the yarn storage wheel, the lower wheel of the yarn storage wheel and the yarn storage wheel

A technology of ceramic rod and yarn storage wheel, applied in textile and papermaking, knitting, weft knitting and other directions, can solve the problems of fluff, easy aggregation of yarn or fluff, yarn breakage, etc., to reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

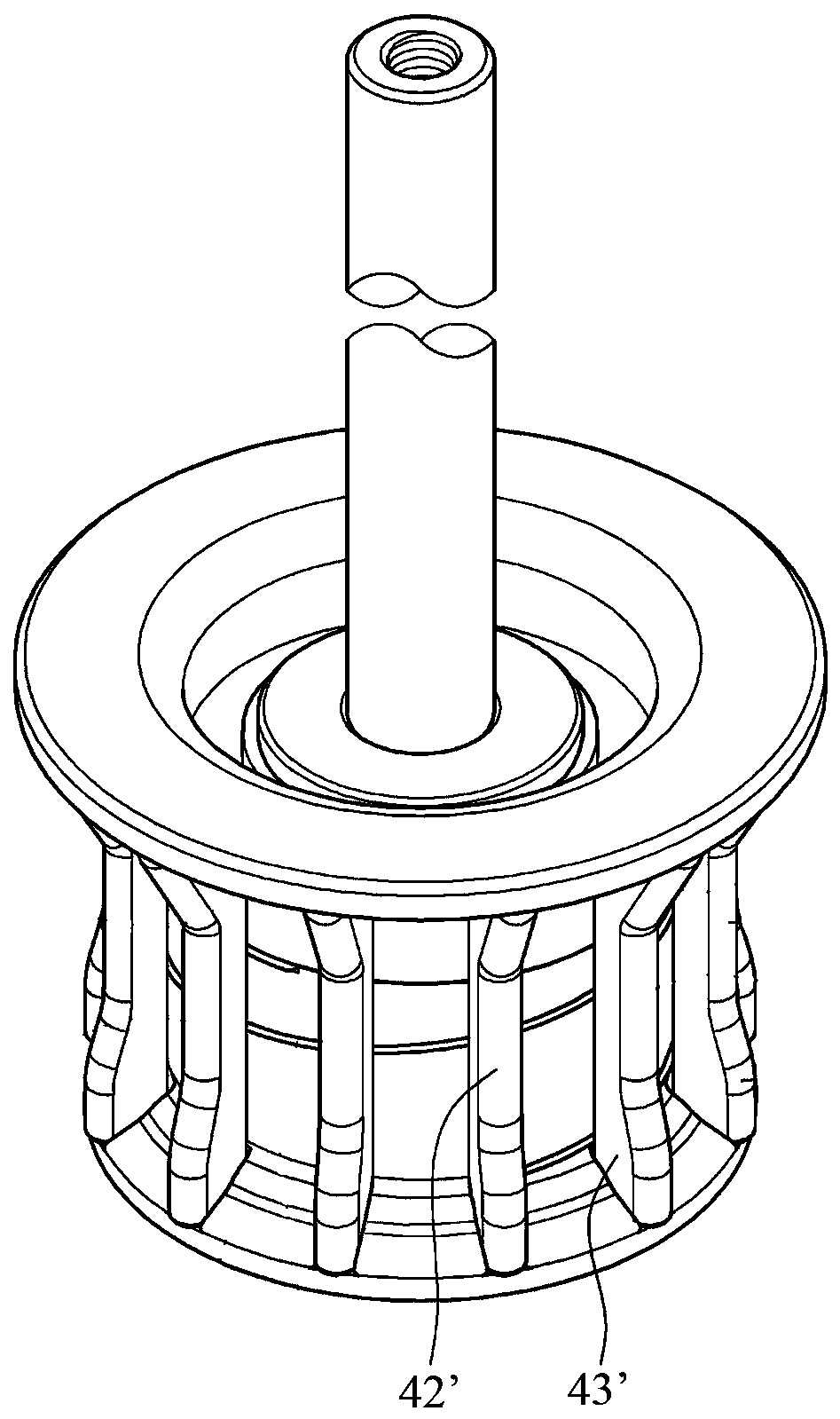

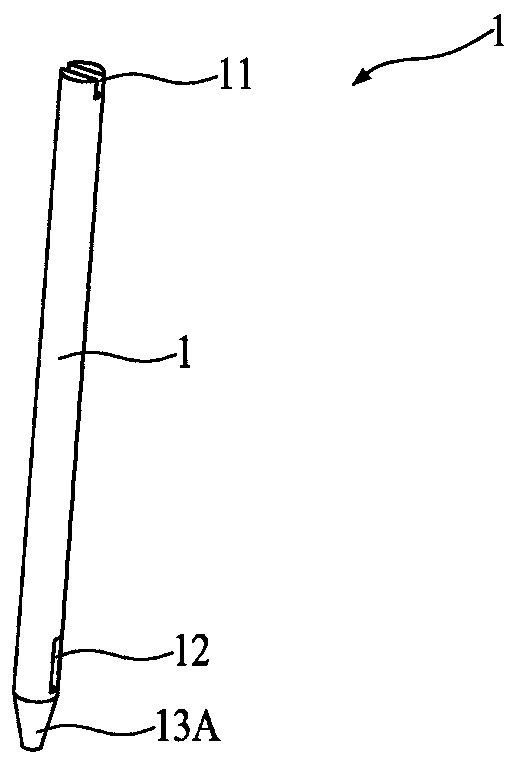

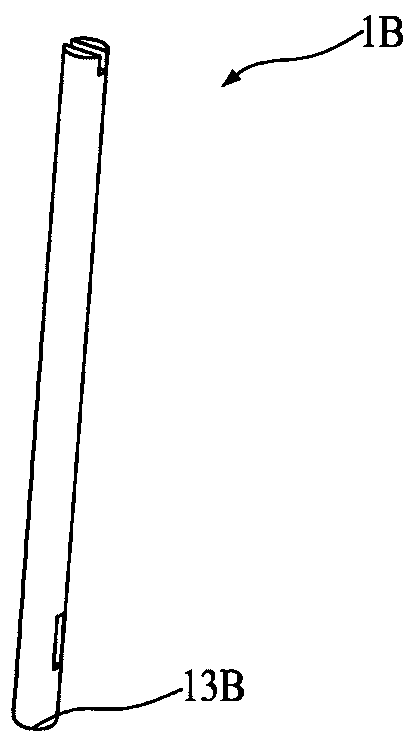

[0028] Such as figure 2 As shown, the ceramic rod of the first yarn storage wheel lower wheel of the present invention, the ceramic rod 1 is a round rod, and its top is provided with a positioning groove 11, the positioning groove is in-line or cross-shaped, and the inner part of the ceramic rod 1 At least one covering groove 12 is provided. By setting the positioning groove 11, when the ceramic rod 1 is assembled with the lower wheel of the yarn storage wheel, the covering groove is located in the arc surface of the inner groove of the lower wheel of the yarn storage wheel, so that The outer arc surface of the ceramic rod 1 can be in contact with the yarn; regarding the setting of the number of coating grooves, the present embodiment preferably has two coating grooves 12, and the two coating grooves 12 are symmetrical along the ceramic rod 1 left and right, up and down. Arranged in a staggered manner, the depth of the coating groove 12 ≤ the radius of the ceramic rod 1, sinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com