Sewing stitch generation method and sewing stitch generation device

A technology of sewing needles and stitches, applied in the field of sewing, can solve the problem of low uniformity of spacing, achieve uniform distribution, improve technology, and meet the effects of industrial needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

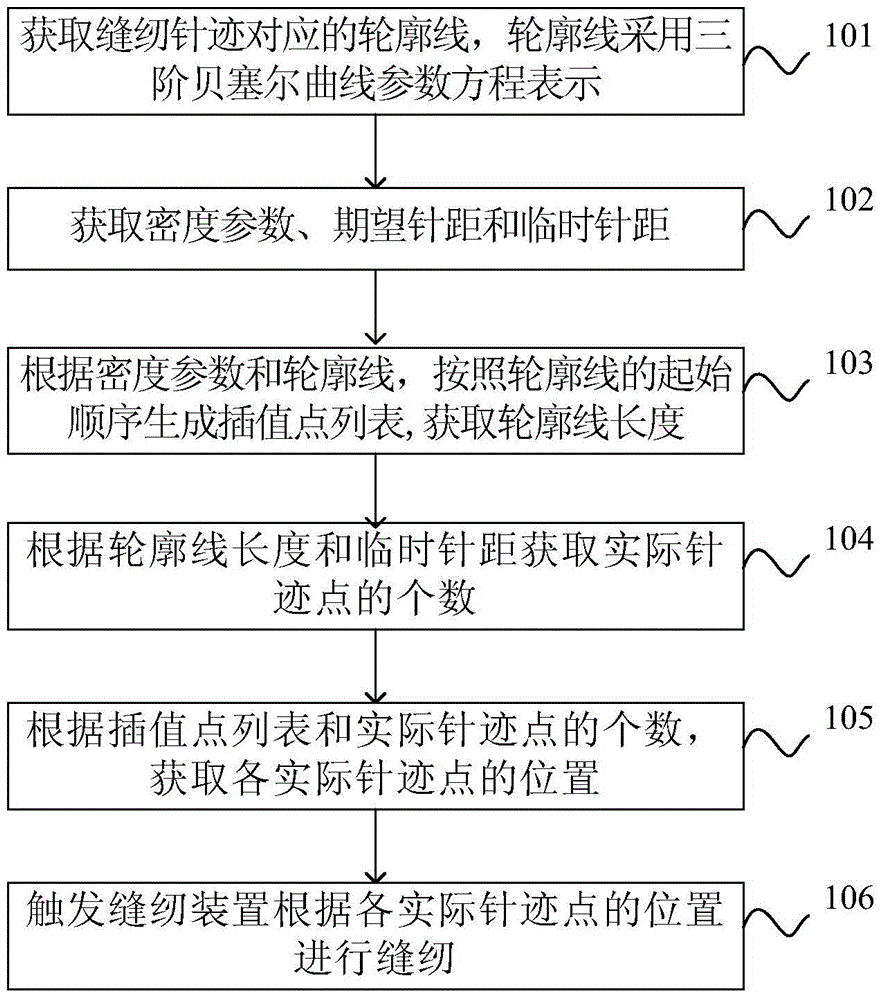

[0025] The execution subject of this embodiment is a sewing stitch generation device. figure 1 It is a schematic flow chart of a sewing stitch generation method according to Embodiment 1 of the present invention, as figure 1 As shown, the sewing stitch generation method of the present embodiment includes:

[0026] Step 101: Obtain the contour line corresponding to the sewing stitch, the contour line is represented by a third-order Bezier curve parameter equation, and go to step 102.

[0027] Specifically, for the contour line to be sewed, it is expressed by a third-order Bezier curve parameter equation, that is, the contour line B(t) using the third-order Bezier curve equation can be expressed as:

[0028] B(t)=P0*(1-t) 3 +3*P1*t*(1-t) 2 +3*P2*t 2 *(1-t)+P3*t 3 ,t∈(0,1]

[0029] Specifically, drawing software can be used to input the data representing the contour line, so as to obtain the values of the parameters P0, P1, P2 and P3 of the third-order Bezier curve equati...

Embodiment 2

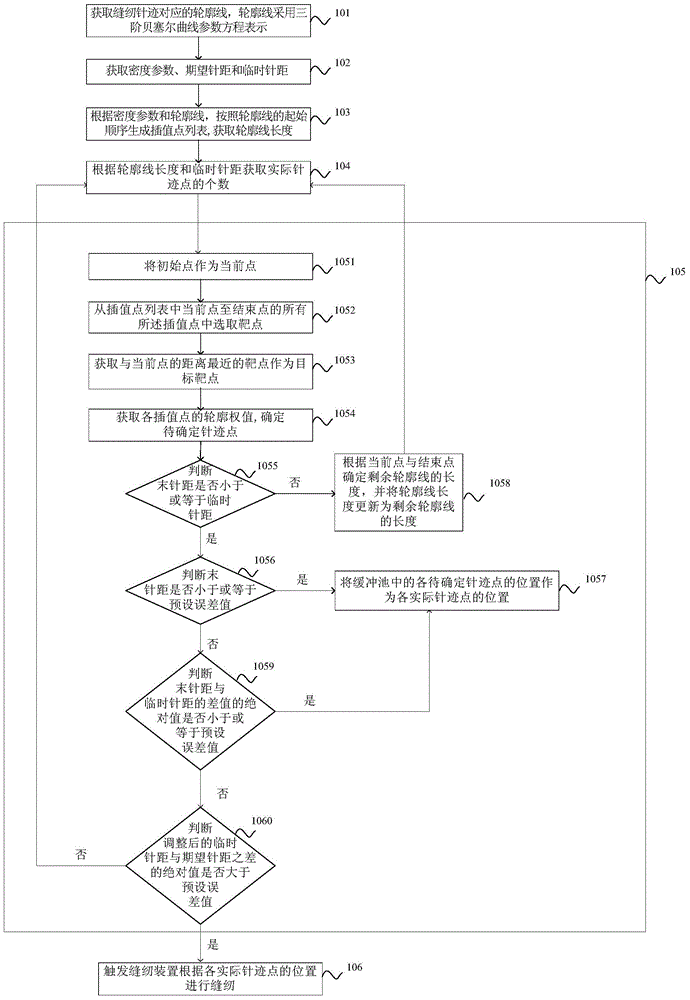

[0047] This embodiment provides a sewing stitch generation method based on the first embodiment. figure 2 It is a schematic flow chart of a sewing stitch generation method according to Embodiment 2 of the present invention, as figure 2 As shown, the sewing stitch generation method of the present embodiment includes:

[0048] Step 101: Obtain the contour line corresponding to the sewing stitch, the contour line is represented by a third-order Bezier curve parameter equation, and go to step 102.

[0049] Step 102: Obtain the density parameter, expected stitch length and temporary stitch length, and go to step 103.

[0050] Step 103: According to the density parameter and the contour line, generate an interpolation point list according to the starting order of the contour line, the interpolation point list includes the positions of each interpolation point on the contour line, the first point in the interpolation point list is the initial point, The last point in the interpol...

Embodiment 3

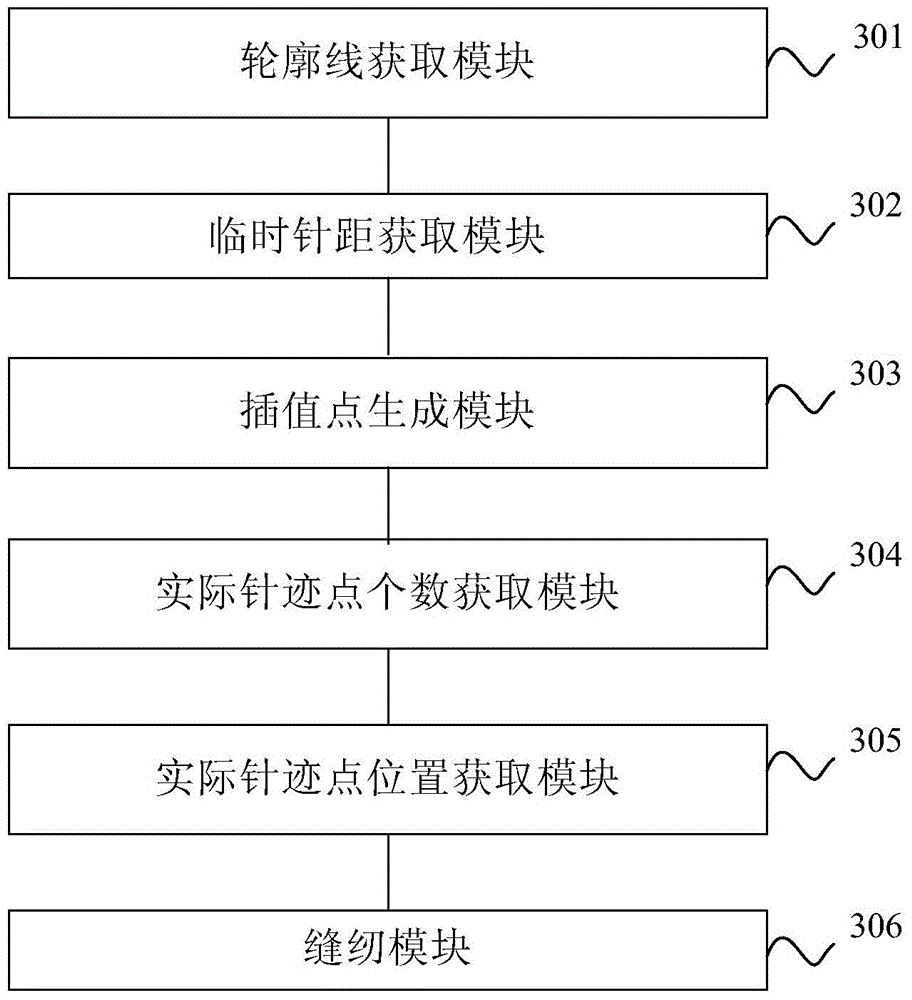

[0081] The present invention also provides a device for generating sewing stitches, which is used to implement the method for generating sewing stitches in Embodiment 1. image 3 It is a structural schematic diagram of a sewing stitch generating device according to Embodiment 3 of the present invention. Such as image 3 As shown, the sewing stitch generation device includes: a contour line acquisition module 301, a temporary stitch distance acquisition module 302, an interpolation point generation module 303, an actual stitch point number acquisition module 304, an actual stitch point position acquisition module 305 and a sewing module 306.

[0082] The contour acquisition module 301 is used to obtain the contour corresponding to the sewing stitch, and the contour is represented by a third-order Bezier curve parameter equation;

[0083] The temporary stitch distance acquisition module 302 is used to obtain density parameters, expected stitch lengths and temporary stitch leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com