A locking device, its clutch and washing machine

A locking device and a washing machine technology, applied in the field of washing machines, can solve the problems of washing and running, one-way bearing failure, and the impossibility of timely cleaning of friction debris, etc., and achieve the effects of reducing production costs, improving service life, and overcoming the phenomenon of running.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

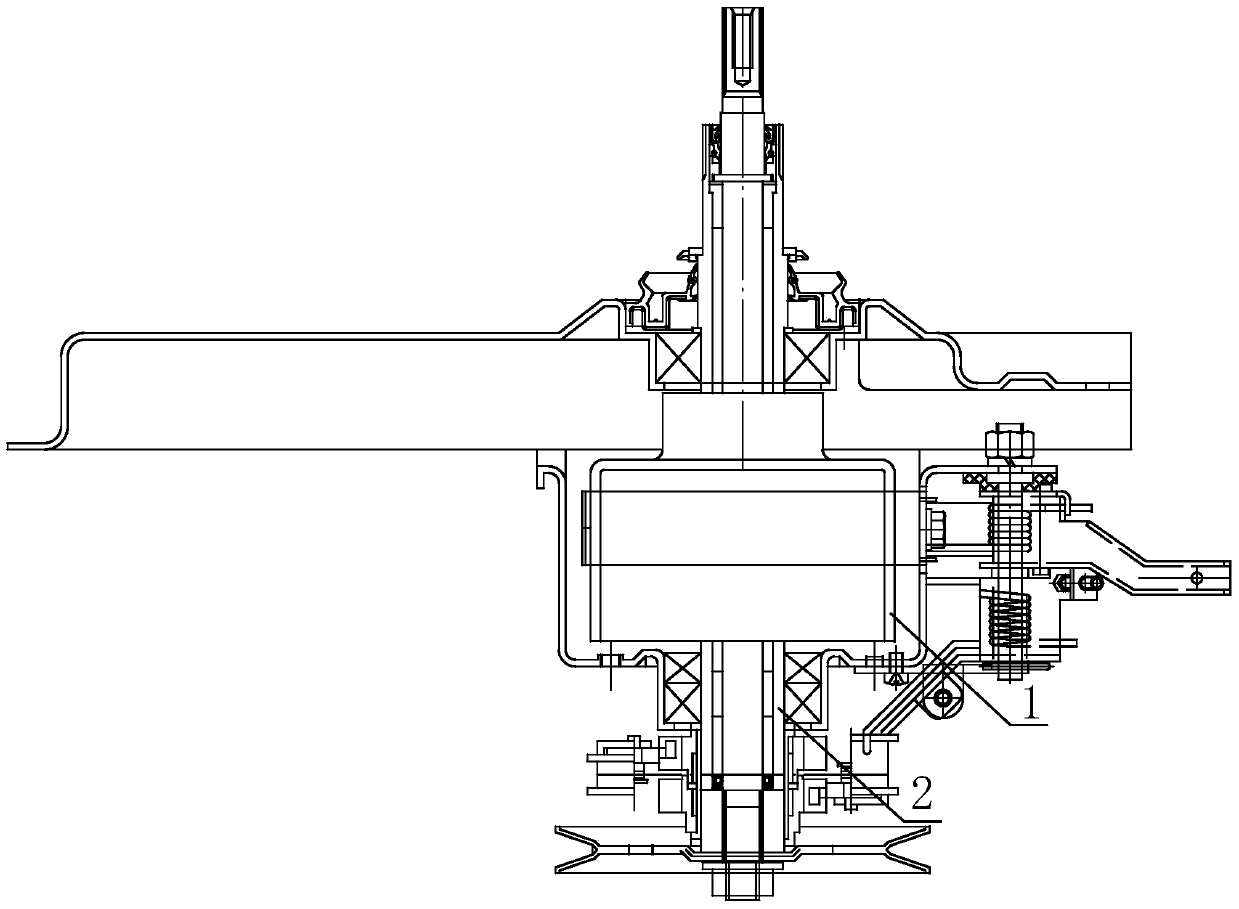

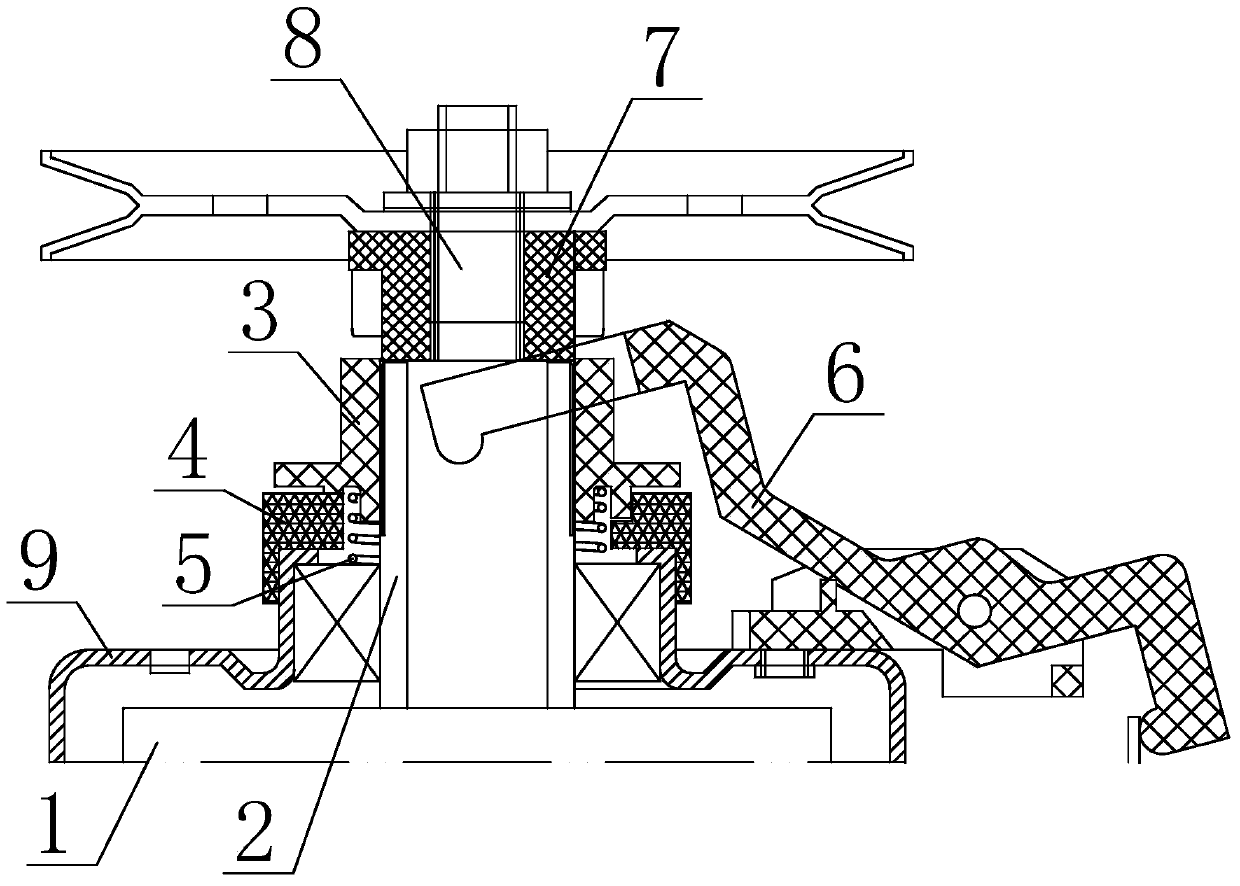

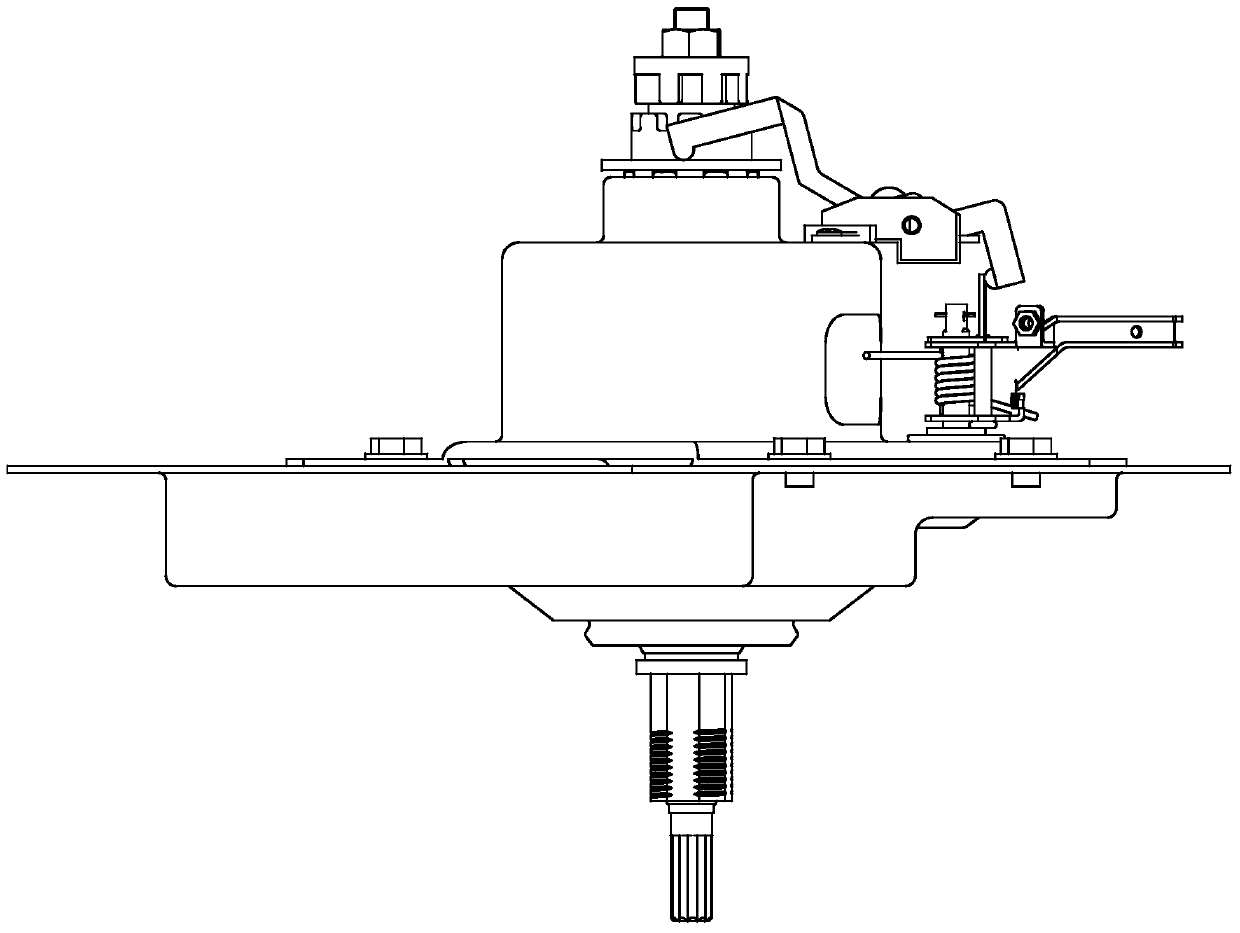

[0032] combine Figure 2-Figure 15 , is a structural schematic diagram of an embodiment of the locking device of the present invention. The locking device includes a brake wheel 1 that is movably installed in the housing 9 in the axial direction. The clutch shaft 2 is fastened to the brake wheel 1 . There is a bearing 11 between them, which is characterized in that: the bearing 11 is a two-way ordinary bearing, the housing 9 is provided with a locking ring 4 connected with it, and the clutch shaft 2 is provided with a The lock sleeve 3 is locked and axially slidably engaged. A movable elastic member 5 is provided on one end surface of the lock sleeve 3 in the axial direction, and a shift fork 6 is movably connected to the other end surface to control its up and down movement.

[0033] More specifically, the clutch shaft 2 and the locking sleeve 3 are connected by splines; the locking ring 4 is arranged inside the housing 9, and the locking ring 4 can also be arranged in the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com