Early drainage method of mine chamber with heavy water

A technology for mines and mines, which is applied in the field of advanced water discharge in Dashui mines, can solve the problems of occupying working faces for a long time, unable to effectively reduce the amount of water inflow in the mines, and not effectively reducing them, so as to reduce the water pressure in the mines and reduce the Probability of water damage and effect of reducing groundwater pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

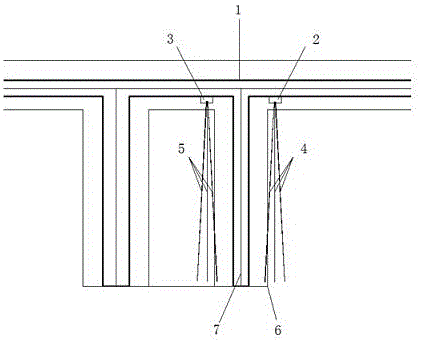

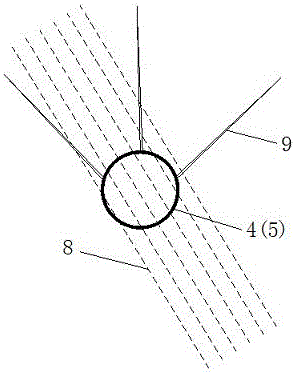

Image

Examples

Embodiment

[0017] Embodiment: Taking a certain Dashui mine in Hebei Province as an example, the specific process of the method for releasing water in advance from the mine house of the Dashui mine is as follows.

[0018] The Dashui Mine adopts the mining method of stage emptying and then filling, in which medium and deep holes are drilled downwards in the rock-drilling roadway, and the ore is collapsed sideways, and the scraper excavates the ore in the mining roadway at the bottom of the mine. The panels are arranged along the strike of the ore body, with a length of 120m, a width equal to the horizontal thickness of the ore body, a height of 50m (stage height), and a width of 15m between the columns. Within the scope of the panel, the mining block is divided along the ore body trend and vertical direction, and the length direction of the ore block is consistent with the ore body trend. The one-step mining block adopts cemented filling, and the second-step mining block mainly uses tailin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com