Polyester gabion box for river channel and bending assembly method

A polyester gabion mesh and polyester gabion technology, which is applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve the problems of non-standard gabion mesh boxes, hidden dangers in safety, etc., and achieve good mechanical performance, The effect of reducing the probability of damage and strong constructability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

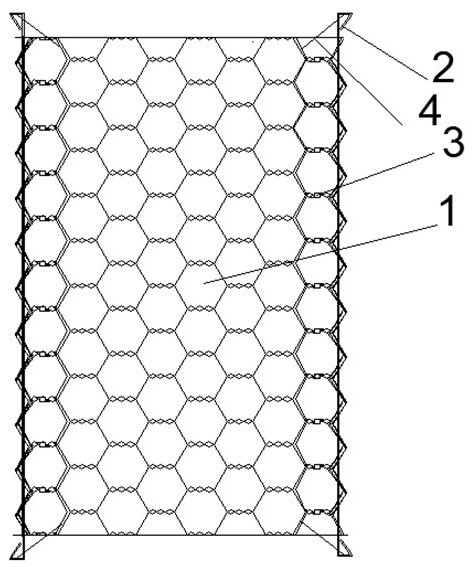

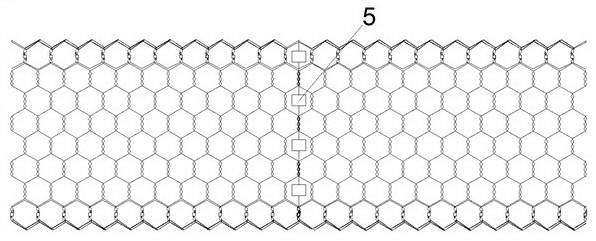

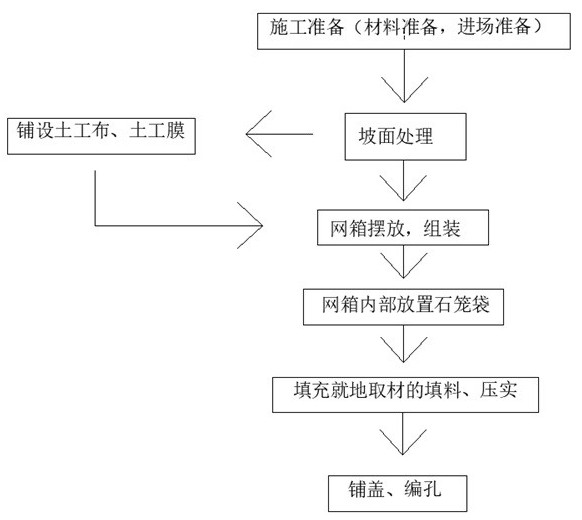

[0035] Such as Figure 1-5 As shown, a bending and assembling method of polyester gabion mesh suitable for river channels is as follows:

[0036] Step 1: The shape is fixed, bend the two side ends of a 2.24-2.3-meter-long polyester gabion net at 12-15 cm, the polyester wire is bent back, and the overlapping lines form a P-shaped structure. Tightly fix the P type, and then erect the other two sides at 50 cm, and the height is 50 cm;

[0037] Step 2: Fold and fix. Use two mesh pieces of the same material with a specification of 1m x 0.75m, fold them into a size of 1m x 0.5m, bend them at 12-15cm from the ends of both sides, and fold again Form the P-shaped structure in step 1, and fix it with buckles;

[0038] Step 3: Combining and fixing, put the two mesh pieces with a specification of 1m×0.5m in step 2 into both sides of the mesh folded in step 1, and insert steel wires into the gaps of the P-shaped structure, and fold back the two ends of the steel wires to fix them. Then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com