Biaxial Rotational Deformation Channel Without Sharp Angle Internal Waverider Variable Geometry Inlet

A technology of air inlet and variable geometry, which is applied in the direction of machines/engines, jet propulsion devices, gas turbine devices, etc., can solve problems such as unsatisfactory performance, increase shock wave structure, increase air flow wetting area, etc., and avoid corner flow , high kinetic energy efficiency, and the effect of increasing gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

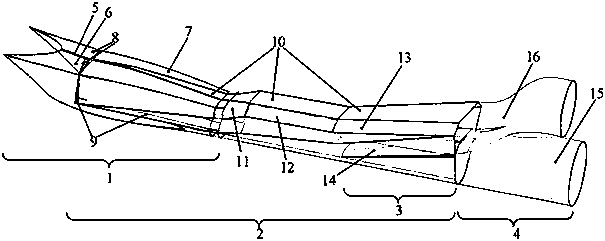

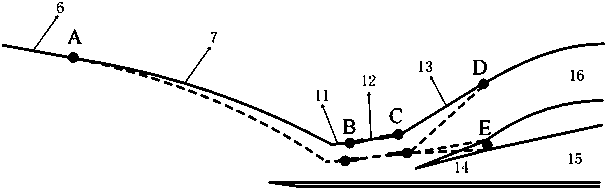

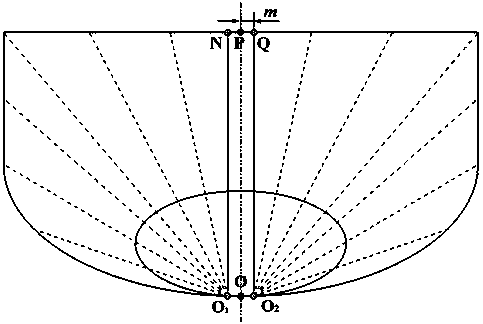

[0035] Aiming at the parallel TBCC intake system whose Mach number ranges from 0-4.0 and the transitional Mach number is 2.5, firstly, according to the double kiss tangent flow theory and the improved arrangement of kiss tangent planes, the waverider inlet with variable cross-section is designed. The design state is that the Mach number of the incoming flow is 4.0, and the Mach number of the throat is about 1.5; the width-to-height ratio of the inlet is 1.8, the arrangement center of the left and right kissing planes deviates from the symmetrical plane by 0.1, the shape of the inlet is circular at the top and bottom, and the cross section of the throat is elliptical . Two symmetrical movable compression surfaces are intercepted on the basic surface of the air inlet in the design state; when the incoming flow velocity decreases, mechanically actuate them by adopting a dual-axis-sealed variable geometry method to enlarge the throat The area and keep the throat Mach number betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com