LED light guide lens

A lens and strip technology, applied in the field of LED lighting, can solve the problems of blood-like clutter, reduce the light mixing efficiency of the light guide lens, etc., and achieve the effect of good light mixing and elimination of blood-like clutter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

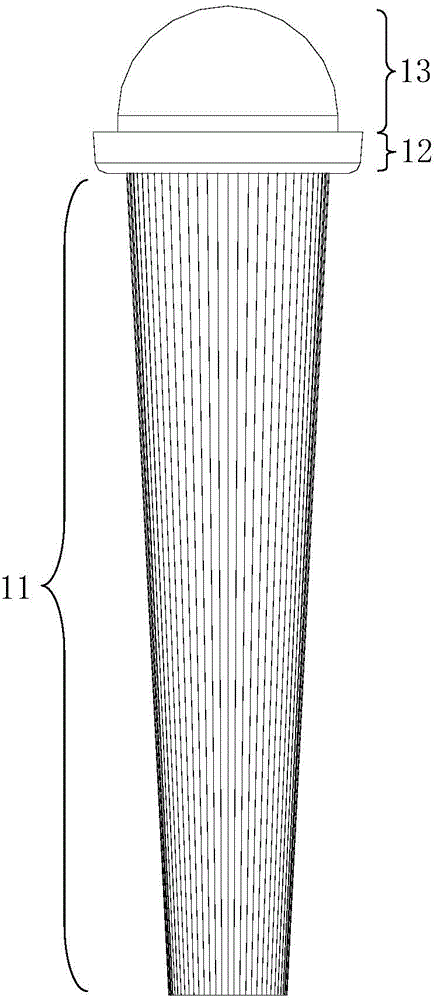

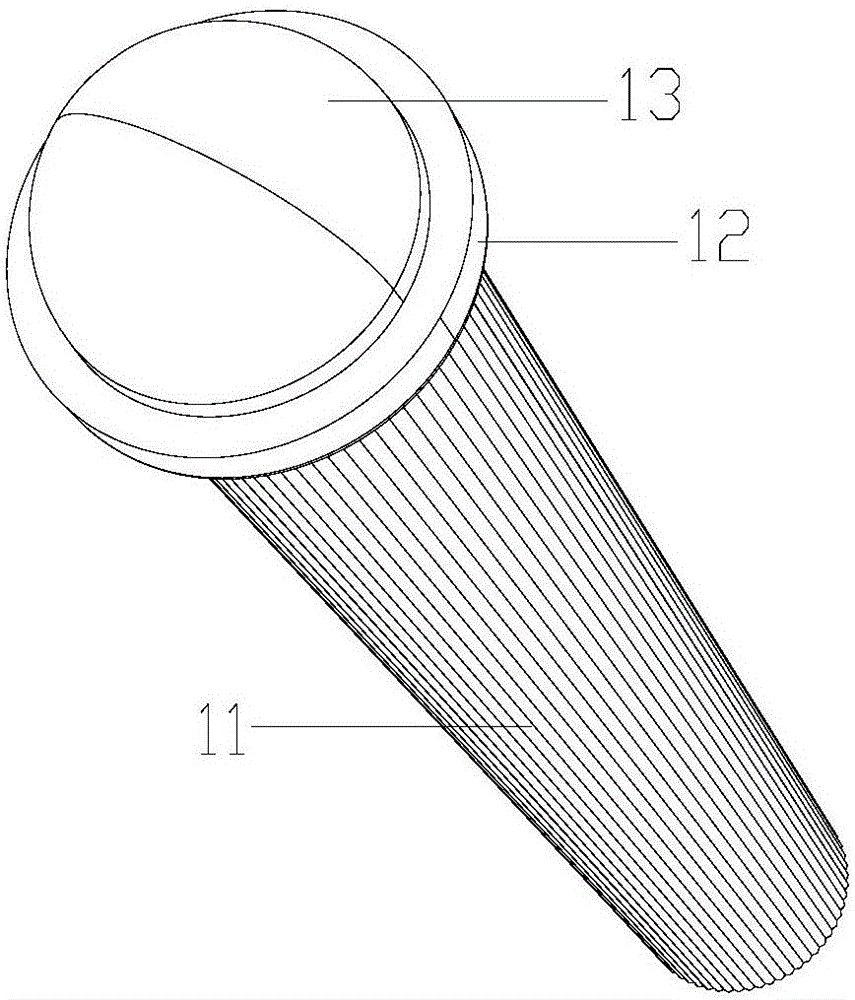

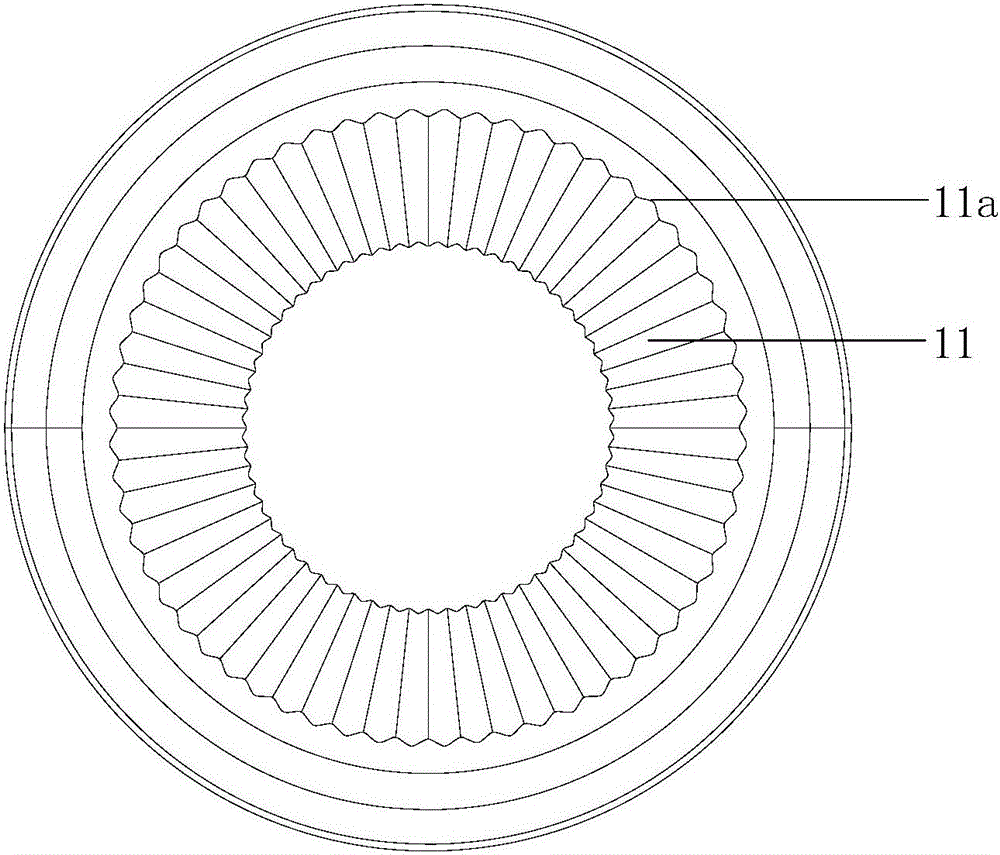

[0034] see figure 1 , figure 2 and image 3 , an LED light guide lens of the present invention, the LED light guide lens is rotationally symmetrical, and includes a long columnar body 11, a flat cylinder 12 and a hemisphere 13 connected in sequence; the long columnar body 11 moves from one end to the other One end gradually becomes larger, and the side of the elongated columnar body 11 is provided with annular wavy fine lines 11a, and the annular wavy fine lines 11a are opposite to the elongated columnar body from the relatively small end of the elongated columnar body The large end extends, and the ring-shaped wavy fine lines 11a are rotationally symmetrical;

[0035] The relatively large end of the elongated columnar body 11 is connected to a flat cylinder 12, and the other end of the flat cylinder 12 is connected to a hemisphere 13. The spherical surface or smooth curved surface of the hemisphere 13 is the light-emitting surface of the LED light guide lens of the present...

Embodiment 2

[0042] see Figure 4 , Figure 5 , Figure 8 and Figure 9 The difference between this embodiment and Embodiment 1 is that the elongated columnar body 11 is polished at the part close to the flat cylinder 12 to have a smooth surface, and the length of the polished portion of the elongated columnar body 11 is elongated 1 / 4 to 1 / 3 of the length of the cylindrical body 11 of shape.

[0043] The elongated columnar body 11 of the LED light guide lens is polished near the flat cylinder 12 because the radial structure will be deformed during processing, and the zoom stroke of the LED light guide lens is limited when the LED light guide lens is used with the zoom lens. The process is equivalent to the zoom lens imaging at different heights of the LED light guide lens, which will image the deformation of the light caused by this processing defect, and the elongated columnar body 11 is polished on the part close to the flat cylinder 12 The method can change the imaging area into a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com