Multi-cavity LED street lamp

A LED street lamp and multi-cavity technology, applied in circuit layout, semiconductor devices of light-emitting elements, lighting and heating equipment, etc., can solve problems such as single light distribution form, low light energy utilization rate, and inability to carry out overall optical design. Achieve the effects of improving light distribution efficiency, high light energy utilization rate, and reducing labor maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

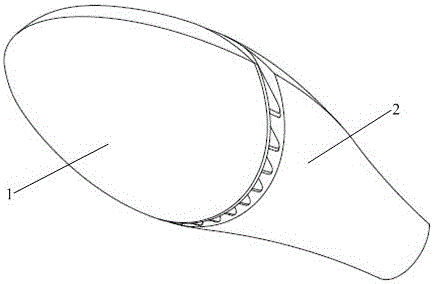

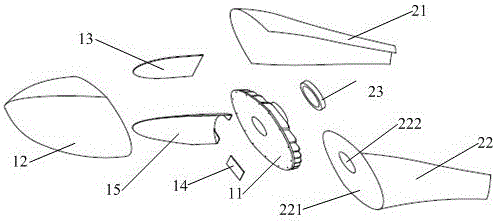

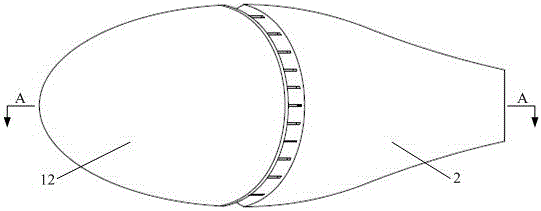

[0036] See attached figure 1 to attach Figure 6 As shown, a multi-cavity LED street lamp includes a front end cover 1 and a rear end cover 2, the front end cover 1 is connected to the rear end cover 2, and the front end cover 1 and the rear end cover 2 each form an independent cavity; The front cover 1 includes a front cover 11 and an LED lens 12, the LED lens 12 is fixed on the front cover 11 to form a closed cavity, and the cavity formed by the LED lens 12 and the front cover 11 is provided with a PCB board 13 and LED light source 14; the front cover 11 is placed obliquely, forming an angle with the horizontal plane, and the rear end cover 2 is fixed on the front cover 11.

[0037] Further, the angle formed by the front cover 11 and the horizontal plane is 0°-40°.

[0038] Further, a reflector 15 is provided in the cavity formed by the LED lens 12 and the front cover 11 , and the reflector 15 is embedded in the LED lens 12 . The LED lens 12 has a large optical cavity, an...

Embodiment 2

[0048] See attached Figure 6 to attach Figure 11 As shown, a multi-cavity LED street lamp includes a front end cover 1 and a rear end cover 2, the front end cover 1 is connected to the rear end cover 2, and the front end cover 1 and the rear end cover 2 each form an independent cavity; The front cover 1 includes a front cover 11 and an LED lens 12, the LED lens 12 is fixed on the front cover 11 to form a closed cavity, and the cavity formed by the LED lens 12 and the front cover 11 is provided with a PCB board 13 and LED light source 14; the front cover 11 is placed obliquely, forming an angle with the horizontal plane, and the rear end cover 2 is fixed on the front cover 11.

[0049] Further, the angle formed by the front cover 11 and the horizontal plane is 0°-40°.

[0050] Further, a reflector 15 is provided in the cavity formed by the LED lens 12 and the front cover 11 , and the reflector 15 is embedded in the LED lens 12 . The LED lens 12 has a large optical cavity, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com