Tunnel type dryer based on drying effect

A tunnel dryer and drying technology, which is applied in the direction of dryers, progressive dryers, drying, etc., can solve the problem that the drying effect cannot be balanced with the uniformity of the drying hot air flow, and achieve the purpose of improving the drying and sterilization effect, The effect of improving the utilization rate and improving the import speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

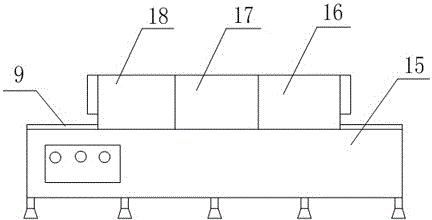

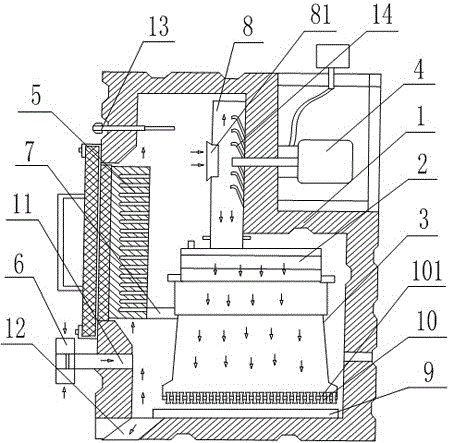

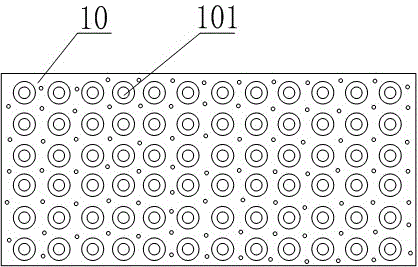

[0041] Such as Figure 1 to Figure 3 As shown, the tunnel dryer based on the drying effect includes a bracket 15, the upper end of the bracket 15 is provided with a conveying mechanism 9, and the bracket 15 is sequentially provided with a preheating device 16, a sterilizing device 17 and Cooling device 18, the sterilizing device 17 includes a housing 1, the housing 1 is provided with an air inlet 11, an air outlet 12, a conveying mechanism 9 is arranged below the inside of the housing 1, and the inside of the housing 1 is arranged above the air inlet 11 There is a heating device 5, and the inside of the housing 1 is provided with an air collecting tube 8, the side wall of the air collecting tube 8 is provided with an air inlet 81 that cooperates with the heating device 5, and the housing 1 is provided with a heating layer that cooperates with the air collecting tube 8 Air flow fan 4, the lower end of described air gathering cylinder 8 is provided with second filter 2, and the ...

Embodiment 2

[0043] Such as Figure 1 to Figure 3As shown, this embodiment is based on Embodiment 1, the air inlet 11 is provided with a first filter 6; the housing 1 is provided with a temperature sensing device 13 at the air outlet of the heating device 5, and the temperature sensing Device 13 is a temperature sensor, and can also be a thermocouple; a baffle plate 7 is arranged between the heating device 5 and the wind gathering hood 3; the inner diameter of the wind gathering tube 8 is less than the inner diameter of the wind gathering hood 3; The inner diameter of 101 gradually increases from the middle to both ends; the inner diameter of the port of the ventilation pipe 101 is 4mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com