Pressure sensor

A pressure sensor and carbon nano-layer technology, applied in the field of sensors, can solve the problems of poor tactile sensation, sensitivity, and inability to measure lateral pressure, etc., and achieve good tactile feedback effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

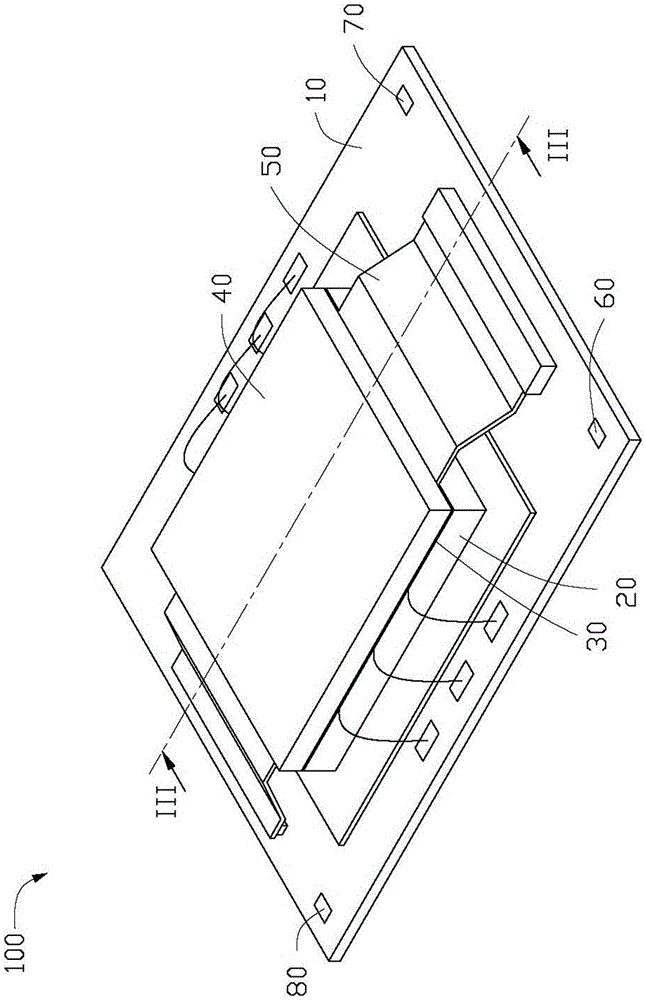

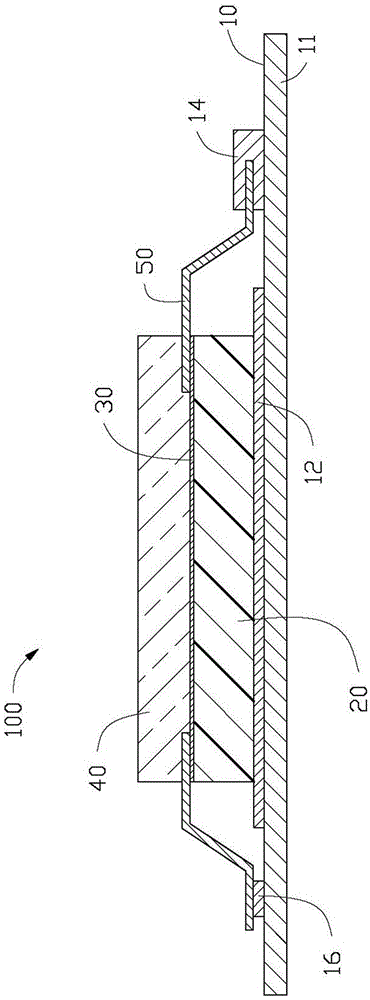

[0015] see figure 1 , the pressure sensor 100 provided by the present invention includes a substrate 10, a deformable substrate 20, a carbon nanolayer 30, a cover plate 40, two flexible circuit boards 50, a resistance measuring device 60, and a capacitance measuring device 70 and a processor 80 . The deformable substrate 20 is disposed on the base 10 . The cover plate 40 covers the deformable base material 20 . The carbon nano layer 30 is located between the deformable substrate 20 and the cover plate 40 . The upper and lower surfaces of the carbon nano layer 30 are respectively in contact with the cover plate 40 and the deformable substrate 20 .

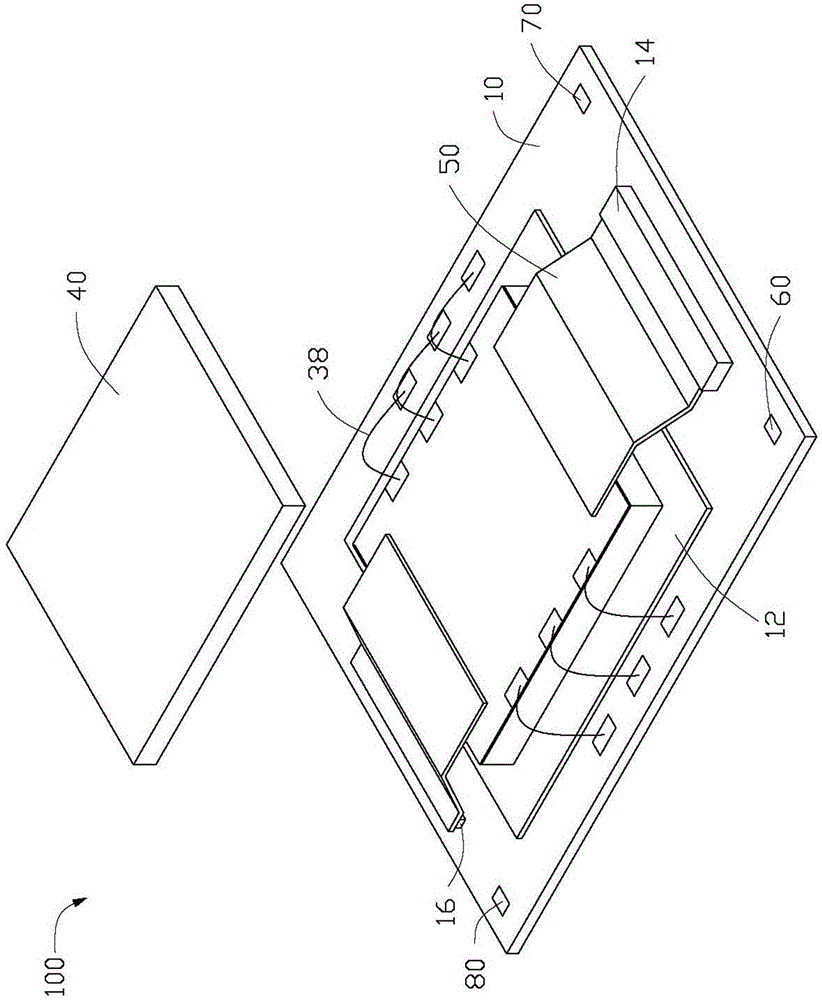

[0016] see figure 2 and image 3 , the base 10 includes a substrate 11 , a solder pad 12 , a connector 14 and a plurality of solder joints 16 . The pads 12 , the connectors 14 and the plurality of solder points 16 are all disposed on the substrate 11 . The substrate 11 is a cuboid structure. The substrate 11 can be a rigid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com