Method for making pole piece and battery cell, and battery core and pole piece for wound battery

A winding type pole piece technology, which is applied in the production of pole pieces and batteries, and in the field of winding battery batteries and pole pieces, can solve the problems of inconvenient outlet of the pole ears, and achieve the convenience of wire outlet and arrangement, and solve the problem of pole pieces. The effect of inconvenient ear access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1 of the production method of the pole piece in the present invention: the production method of the pole piece in this embodiment is the same as the production method of the positive electrode piece in the foregoing embodiment, so it will not be repeated.

Embodiment 2

[0053] Embodiment 2 of the manufacturing method of the pole piece in the present invention: the manufacturing method of the pole piece in this embodiment is the same as the manufacturing method of the negative electrode piece in the above-mentioned embodiment, so it will not be repeated.

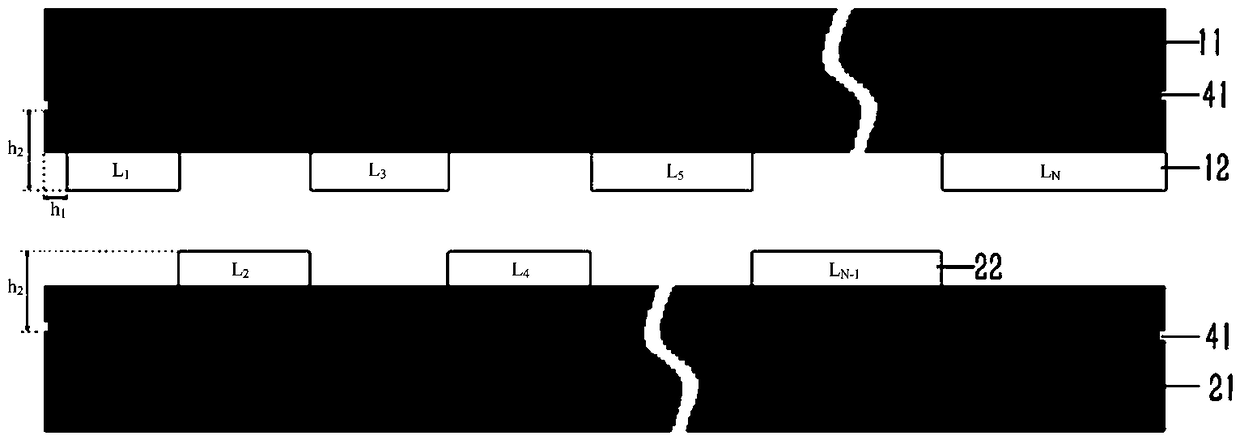

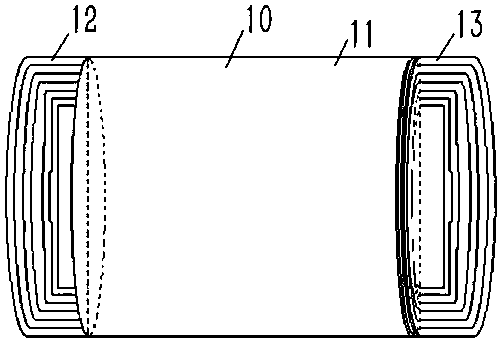

[0054] Embodiment 1 of the pole piece in the present invention: the pole piece in this embodiment is the intermediate product of the above-mentioned manufacturing method of the battery-A positive electrode piece, such as figure 2 As shown, the pole piece includes a band-shaped A-coated area 11. Mark holes 41 are respectively provided at both ends of the A coating area 11, and the Mark holes 41 are used as the start and end points of the pole piece. The coating area is divided into a number of segments from the start point to the end point in sequence, and the length of each segment satisfies the formula: L N =L 0 +N*π*(d 1 +d 2 +2*d 3 )*(1+K), where N: the serial number counted from the beginni...

Embodiment 3

[0060] The third embodiment of the pole piece in the present invention: the difference between this embodiment and the pole piece embodiment 1 is that the pole piece is an A negative electrode piece that is adapted to the A positive electrode piece to be wound into the same cell. Each segment of the coating area of the film satisfies the formula: L N =L 0 +(N-1)*π*(d 1 +d 2 +2*d 3 )*(1+K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com