Vacuum vapor phase cleaning jig and method for thick-film deep-cavity hybrid integrated circuit

A hybrid integrated circuit and cleaning jig technology, which is applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problem of inconvenient access to fixtures, and achieve the effect of easy cleaning operation, convenient fixing, and solving inconvenience in picking and placing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

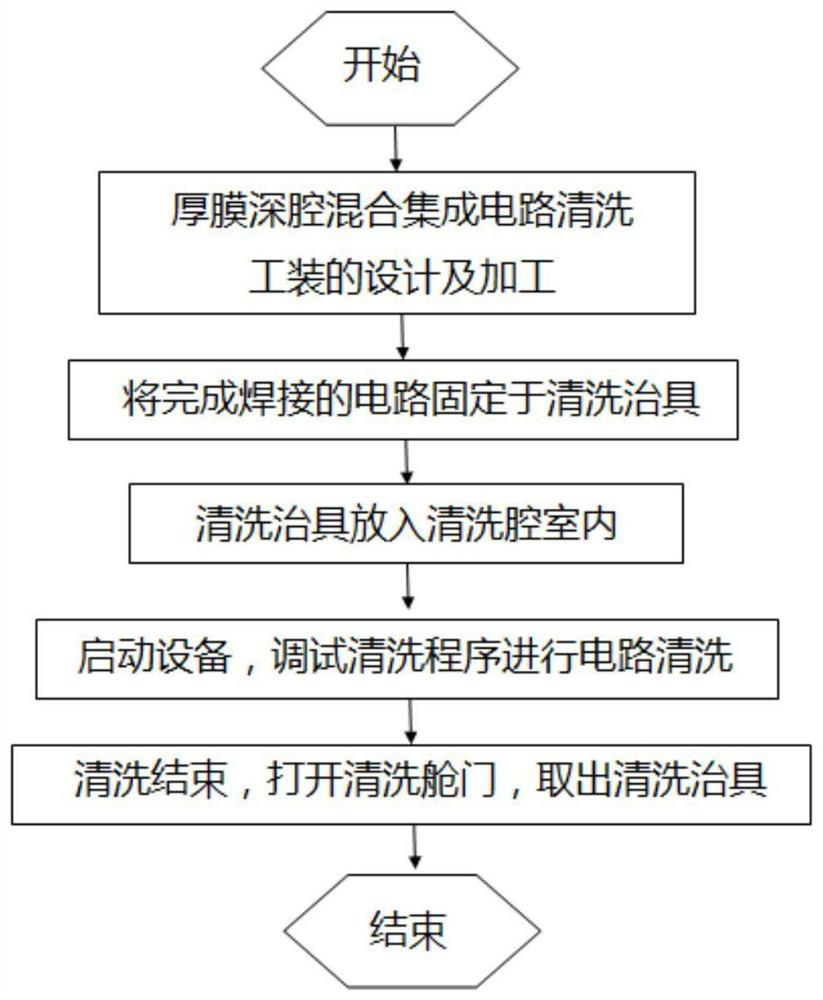

[0051] The invention discloses a vacuum vapor phase cleaning method for a thick-film deep-cavity hybrid integrated circuit, which specifically comprises the following steps:

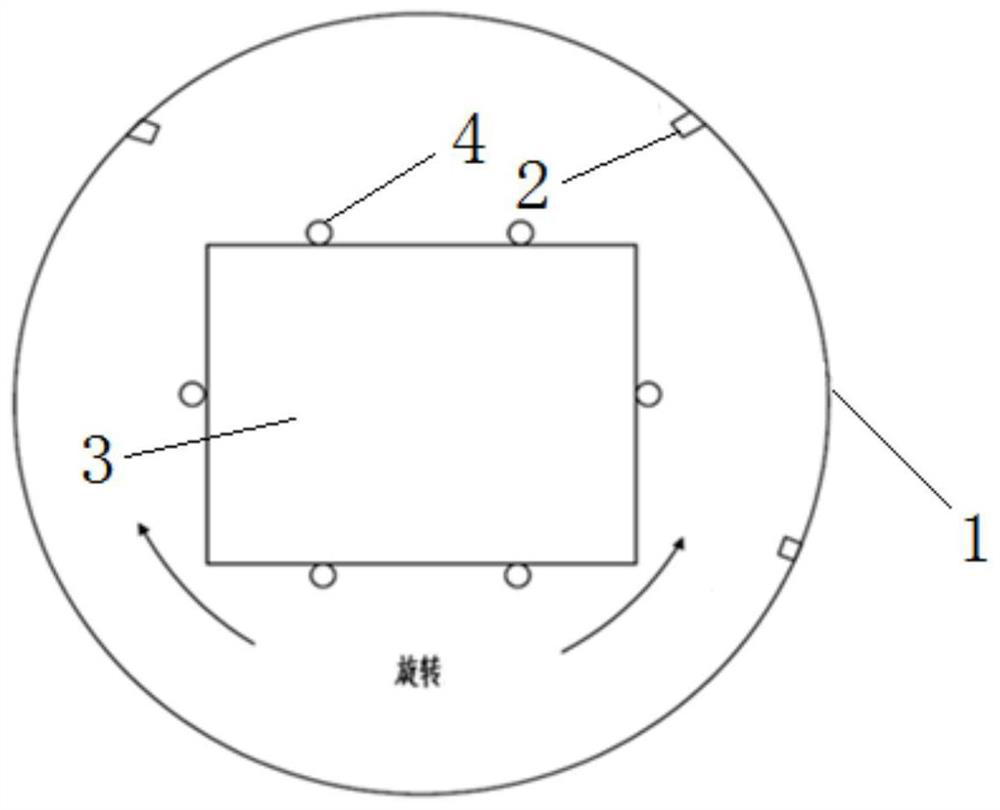

[0052] Step 1. According to the above description of the cleaning jig, make and install the cleaning jig, and install the support bar 9 with the same structure and position as the upper end at the front, rear, and lower ends of the cleaning jig;

[0053] The welded thick-film deep-cavity hybrid integrated circuit is sequentially clamped on the four rectangular surfaces of the upper, lower, front and rear of the cleaning fixture by using the fastening block 8;

[0054] Step 2. Place the cleaning jig that has clamped the thick-film deep-cavity hybrid integrated circuit in the cleaning chamber of the vacuum vapor phase cleaner to ensure that the cleaning jig is completely fixed so that the thick-film deep-cavity hybrid integrated circuit is The cleaning chamber rotates;

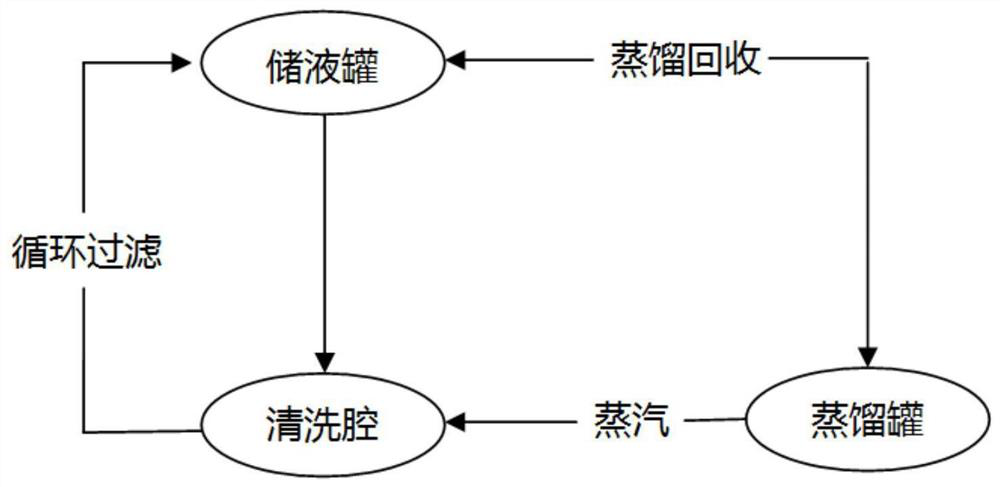

[0055] Step 3. Start the cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com