Capacitive coupling structure for metal cavity filter product

A technology of capacitive coupling and metal cavity, which is applied in the direction of waveguide devices, resonators, electrical components, etc., can solve the problem of suppressing strict product consistency and achieve short debugging time, stable performance and easy production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

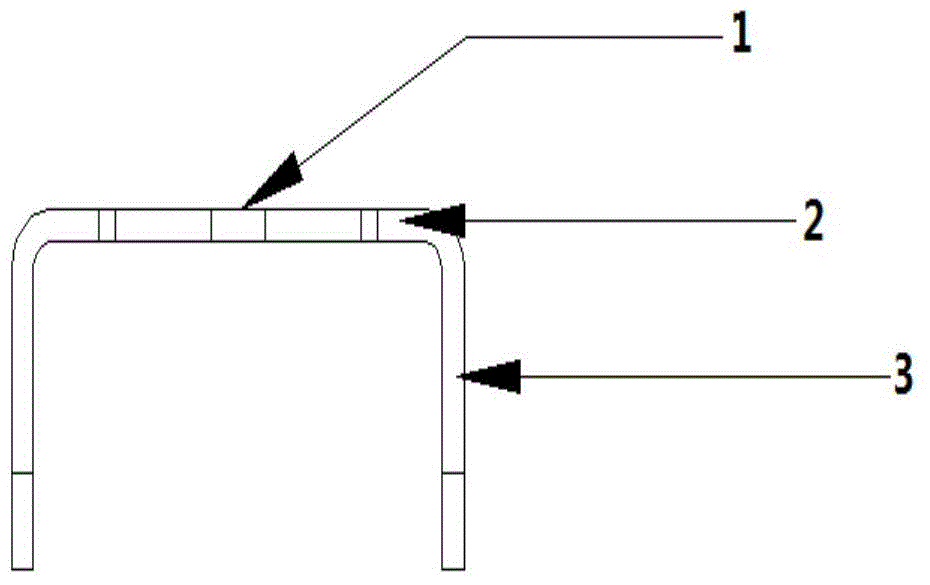

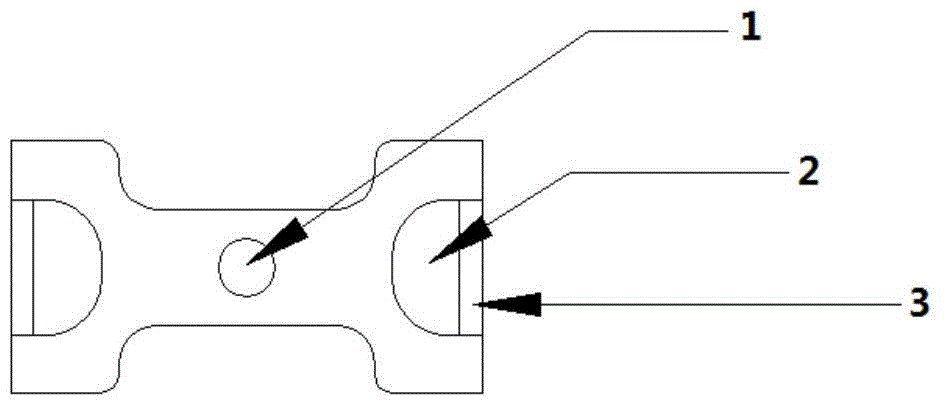

[0025] Such as figure 1 with figure 2 As shown, a capacitive coupling structure for metal cavity filter products, the structure is U-shaped or inverted U-shaped, including a lateral support medium and coupling plates 3 installed at both ends of the transverse support medium, and each coupling plate has a There are U-shaped holes 2 for metal debugging screws to pass through. The metal debugging screws on the cover plate can be adjusted in the U-shaped holes 2 of the coupling sheets on both sides to achieve the purpose of variable coupling capacitance.

[0026] Medium screw holes 1 for medium screws to pass through are provided on the lateral support medium. The medium screw hole 1 is provided with one center position for laterally supporting the medium. The lateral support medium is provided with symmetrically arranged U-shaped grooves.

[0027] The capacitive coupling structure of the metal filter product, the adjustable coupling screw of the U-shaped hole 2 avoids contact...

Embodiment 2

[0029] There are multiple medium screw holes 1 arranged horizontally or vertically. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com