Chip power supply circuit, chip, ink cartridge

A technology for power supply circuits and chips, applied in battery circuit devices, circuit devices, current collectors, etc., can solve the problems of wasting power, long capacitor charging time, and troublesome battery replacement and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

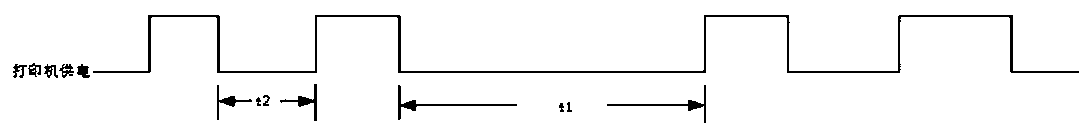

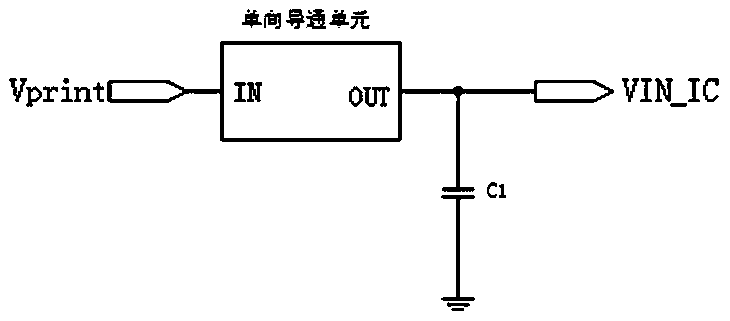

[0029] An ink box, the ink box chip includes a chip circuit and a chip power supply circuit. The main input terminal Vprint of the chip power supply circuit is used to electrically connect with the power output terminal of the printer, and the main output terminal VIN_IC of the chip power supply circuit is connected to the power input terminal of the chip circuit.

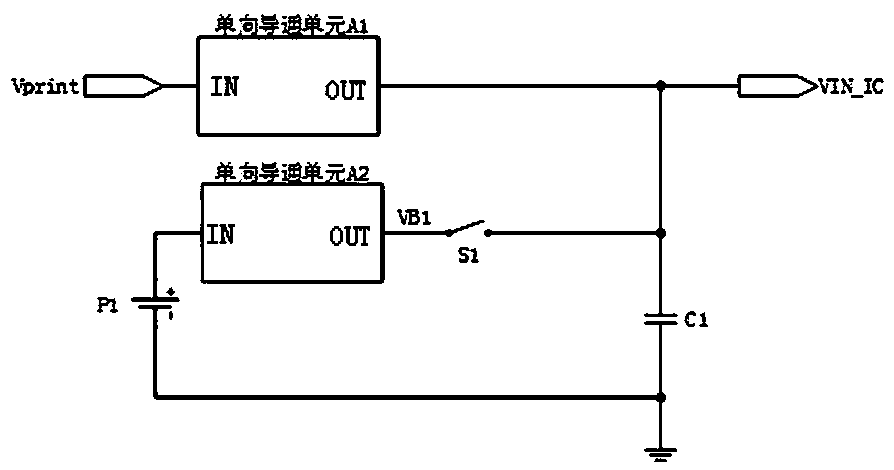

[0030] Such as image 3 , the total input terminal Vprint of the chip power supply circuit is connected to the total output terminal VIN_IC through the unidirectional conduction unit A1, the input terminal of the unidirectional conduction unit A1 is connected to the total input terminal Vprint, and the output terminal of the unidirectional conduction unit A1 is connected to the total output terminal VIN_IC. The negative pole of the battery P1 is grounded, and a one-way conduction unit A2 and a controlled switch S1 are provided between the positive pole of the battery P1 and the total output terminal VIN_IC. The in...

Embodiment 2

[0038] The chip circuit pulls Battery_EN high at the beginning of each command (not just the characteristic command) of the printer, and the path from the battery to the power input terminal of the chip circuit is turned on, and keeps Battery_EN high for t3 time (greater than 100ms). After t3, battery_EN is pulled low, and the path from the battery to the power input terminal of the chip circuit is disconnected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com