Vehicle idle-speed stepping motor provided with sealing sleeve

A stepper motor and sealing sleeve technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of shortening the service life of air filter precision components, obstruction of silt in the idle motor, and large gaps in the shaft pin sockets, etc. Achieve significant fuel-saving effect, novel and simple structure, and improve sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

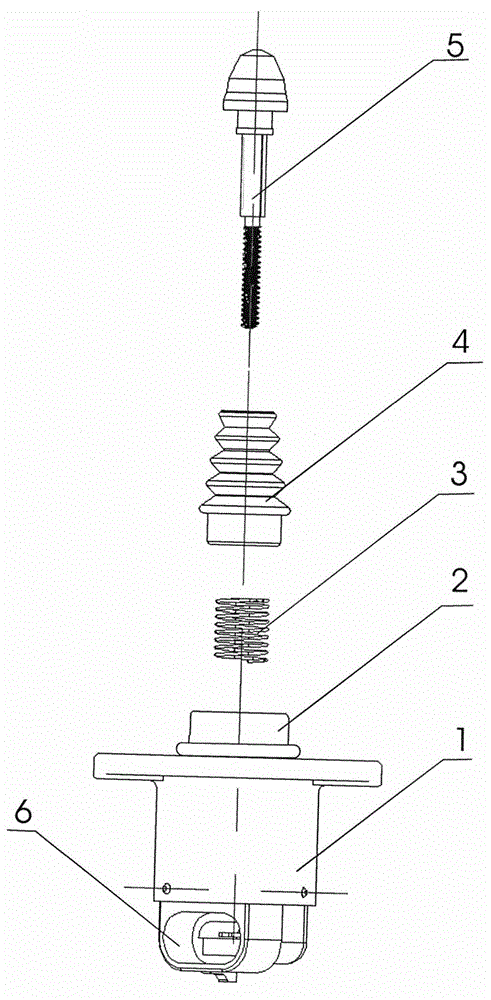

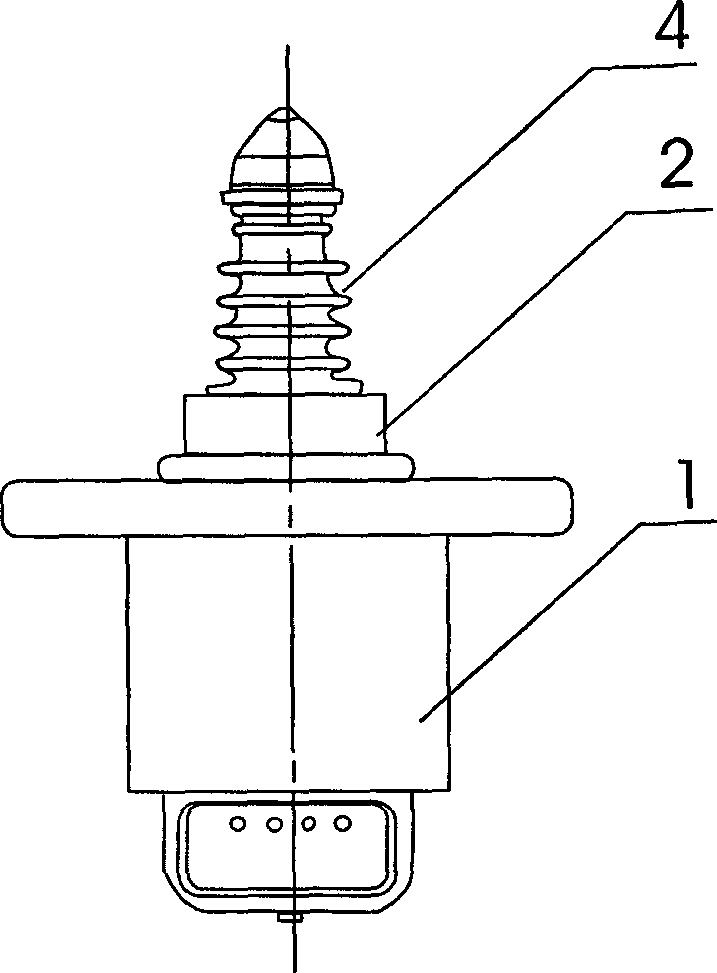

[0010] In an example, the shaft pin socket (2) is located in the middle of the top of the idle motor base (1) of the automobile stepping motor, and the bottom of the plastic sealing sleeve (4) is embedded in the shaft pin socket (2), so The compression spring (3) is sleeved in the inner cavity of the plastic sealing sleeve (4), and the diameters of the two are compatible, and the shaft pin (5) passes through the cavity of the plastic sealing sleeve (4) and the compression spring (3) It is screw-connected with the idle motor base (1) of the automobile stepper motor.

[0011] The above are the best implementation modes of the present invention, and simple modifications and replacements by those skilled in the art are within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com