Faeces cleaning device for goose shed

A cleaning device and goose house technology, applied in poultry cages or houses, application, poultry industry, etc., can solve the problems of poor cleaning effect, waste of water resources, difficult cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

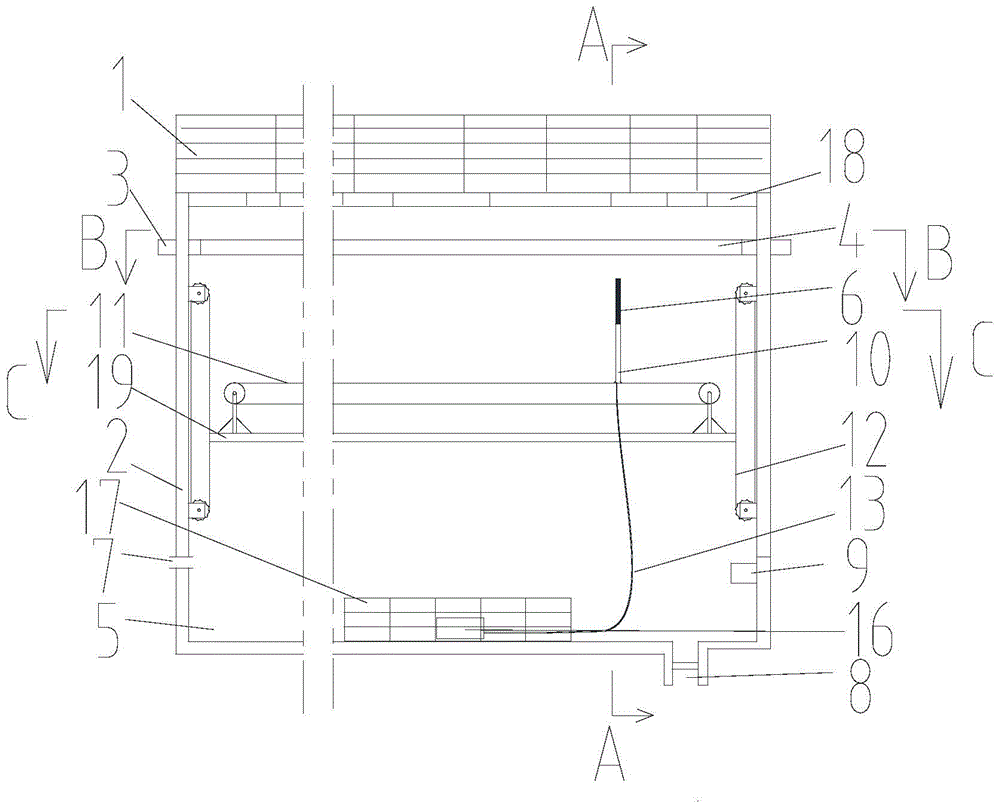

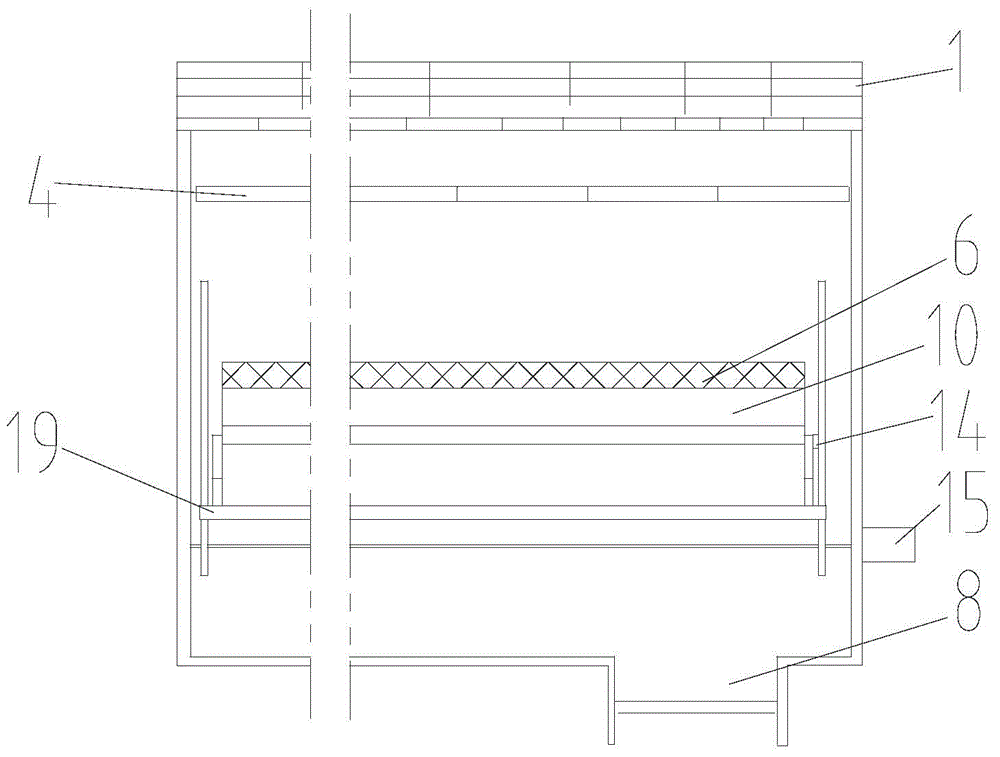

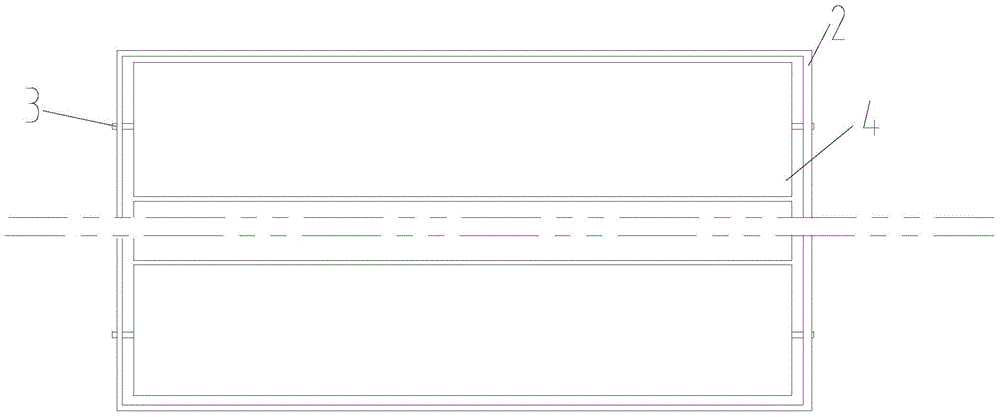

[0012] as attached figure 1 A kind of goose house excrement cleaning device shown in —4, comprises cleaning tank 5, installation frame 2, the goose house 1 that the bottom is rectangular, lifting frame 19, motor, water pump 16, brush holder 10 and brush body 6, cleaning tank 5 One side is provided with a water injection port 7, and the other side is provided with a switchable sewage discharge port 8. Disinfectant water is provided in the cleaning tank 5. The inner wall of the cleaning tank 5 is also provided with a water level sensor 9 for controlling the amount of disinfectant water. The upper ends of both sides are provided with installation frames 2; the bottom of the goose house 1 is a net bed 18, and the two sides of the net bed 18 are fixedly connected to the installation frame 2. The rotating shaft 3 at both ends of the plate 4 is installed on the two mounting frames 2, and the rotating shaft 3 is connected with a motor; a pair of up and down moving chains 12 are respec...

Embodiment 2

[0016] as attached figure 1 A kind of goose house excrement cleaning device shown in —4, comprises cleaning tank 5, installation frame 2, the goose house 1 that the bottom is rectangular, lifting frame 19, motor, water pump 16, brush holder 10 and brush body 6, cleaning tank 5 One side is provided with a water injection port 7, and the other side is provided with a switchable sewage outlet 8. Disinfectant water is provided in the cleaning tank 5, and a water level sensor 9 for controlling the amount of disinfectant water is also provided on the inner wall of the cleaning tank 5; The upper ends of both sides are provided with installation frames 2; the bottom of the goose house 1 is a net bed 18, and the two sides of the net bed 18 are fixedly connected to the installation frame 2. The rotating shaft 3 at both ends of the plate 4 is installed on two installation frames 2, and the rotating shaft 3 is connected with a motor; a pair of up and down moving chains 12 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com