Double-spiral type plastic extrusion device

An extrusion device and screw-type technology, which is applied in the field of double-screw plastic extrusion devices, can solve the problems of material confusion, inconvenient use, and affecting work quality, and achieve the effect of easy adjustment and waste saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

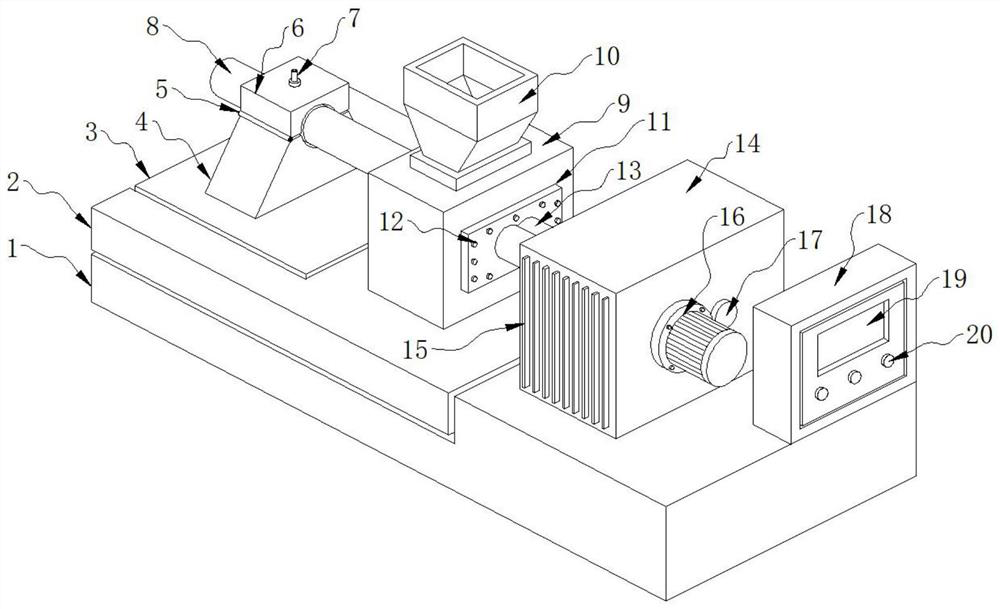

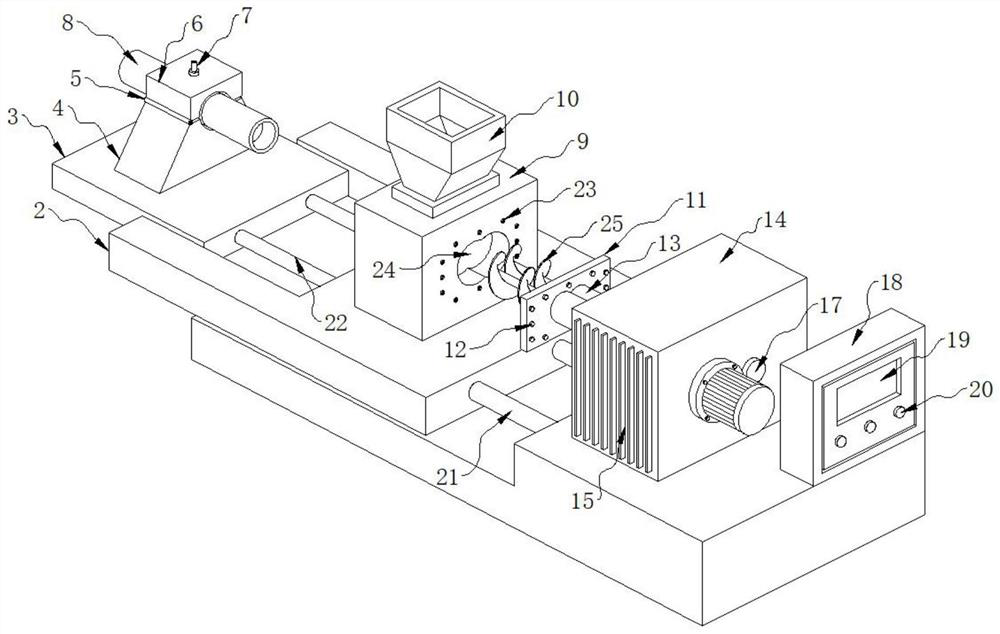

[0029] As a preferred embodiment of the present invention, an electric push rod-21 is installed on the base 1, and one end of the electric push rod-21 is fixed on the fixed seat 2, and an electric push rod is installed inside the fixed seat 2. Rod two 22, one end of said electric push rod two 22 is fixed on the movable seat 3.

[0030] As a preferred embodiment of the present invention, the fixed base 2 is fixed with a fixed box 9, the top of the fixed box 9 is equipped with a feed box 10, and the bottom of the feed box 10 is installed on the On the fixed box 9 , a sealing plate 11 is installed on one side of the fixed box 9 .

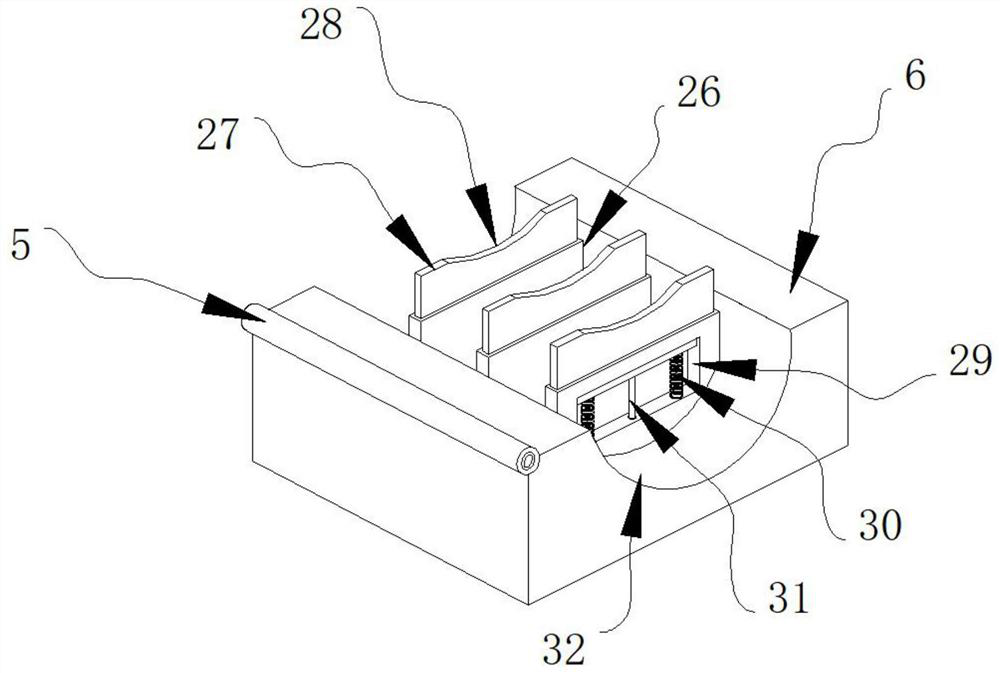

[0031] As a preferred embodiment of the present invention, the sealing plate 11 is equipped with fixing bolts 12, and one side of the fixing box 9 is provided with a cavity 24 and a threaded hole 23, and the sealing plate 11 is connected with the fixing bolt 12. The threaded holes 23 are matched, and a pipe 13 is welded on one side of the sealing plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com