A forming device for ultra-high pressure hydrostatic extrusion of magnesium alloy pipes

A hydrostatic extrusion and molding device technology, applied in the direction of metal extrusion dies, etc., can solve the problems of difficult plastic molding of magnesium alloy materials, short length of magnesium alloy pipes, etc., and achieve good surface quality, low risk factor, and superior mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

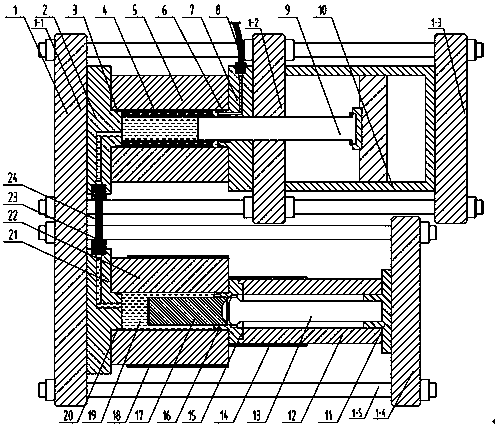

[0035] A forming device for ultrahigh-pressure hydrostatic extrusion of magnesium alloy pipes, which adopts a horizontal structure as a whole, including a frame 1, a pressurizing cylinder 5, an extrusion cylinder 22, a first pressure medium exchange plate 2, and a second pressure medium exchange plate 7. The third pressure medium exchange plate 21 , the extrusion die, the first heating jacket 14 , the second heating jacket 18 and the high-pressure hydraulic pump 10 with the extrusion shaft 9 .

[0036] The frame 1 includes a first fixed beam 1-1, a second fixed beam 1-2, a third fixed beam 1-3, a movable beam 1-4 and a tension column 1-5, and the first fixed beams 1- 1. The second fixed beam 1-2, the third fixed beam 1-3 and the movable beam 1-4. The first fixed beam 1-1 is parallel to the movable beam 1-4, the first pressure medium exchange plate 2 and the third pressure medium exchange plate 21 are respectively fixed on the first fixed beam 1-1, and the second pressure mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com