Assembly line for automotive incandescent lamp

A technology of incandescent lamps and assembly lines, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc. It can solve complex problems and achieve the effects of reasonable process planning, convenient operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

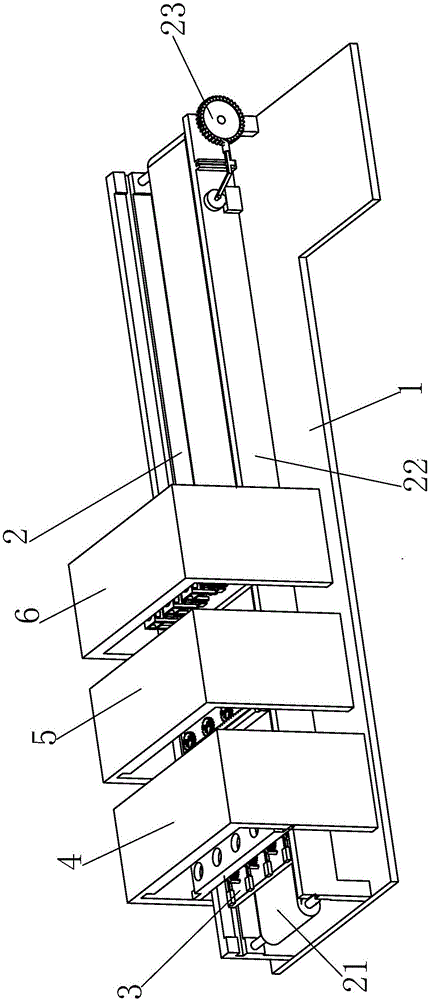

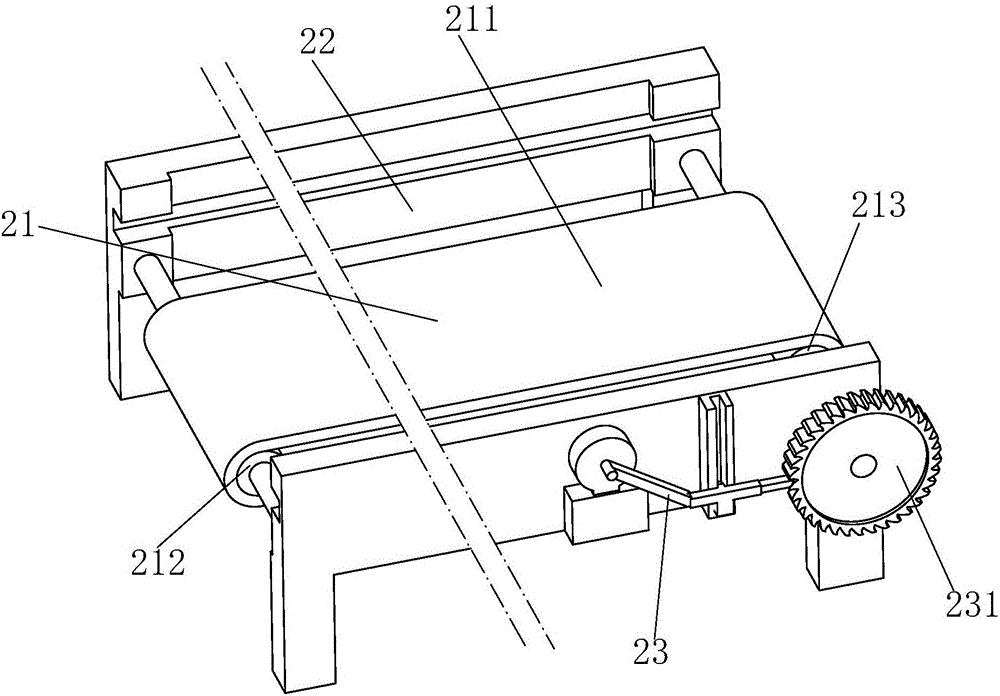

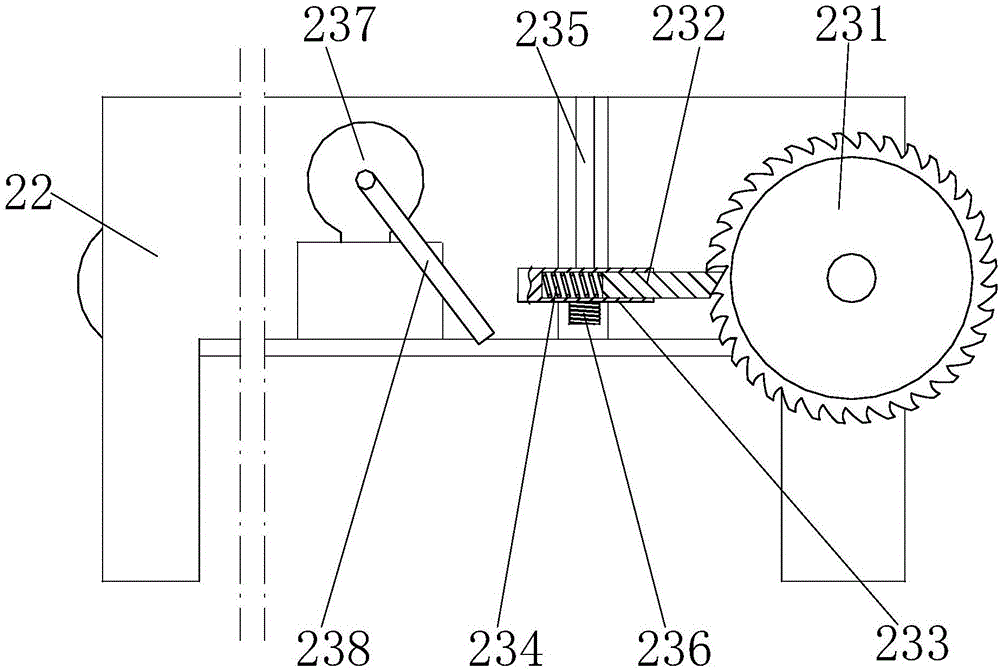

[0055] Such as Figure 1 to Figure 16 As shown, an automobile incandescent lamp assembly line includes a bottom plate 1, on which a horizontal conveying device 2 is arranged, and the horizontal conveying device 2 includes a belt conveying mechanism 21, a horizontal guide rail frame 22 and an intermittent driving mechanism 23, the The intermittent driving mechanism 23 is connected with the belt transmission mechanism 21, and the lamp holder splint 3 mounted on the belt transmission mechanism 21 is slidably installed on the horizontal guide rail frame 22, and the horizontal guide rail frame 22 is arranged in sequence from left to right. There is a wick assembly device 4 , a lampshade assembly device 5 and a screwing reinforcement device 6 .

[0056] The lamp holder splint 3 is the assemb...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap