Accurate part machining method based on measured data feature guidance

A technology for precise processing and actual measurement of data, applied in digital control, instruments, control/regulation systems, etc., can solve problems such as error accumulation, time-consuming, labor-intensive, and inconvenience, and achieve low efficiency, time-consuming, reasonable process planning, and improved accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

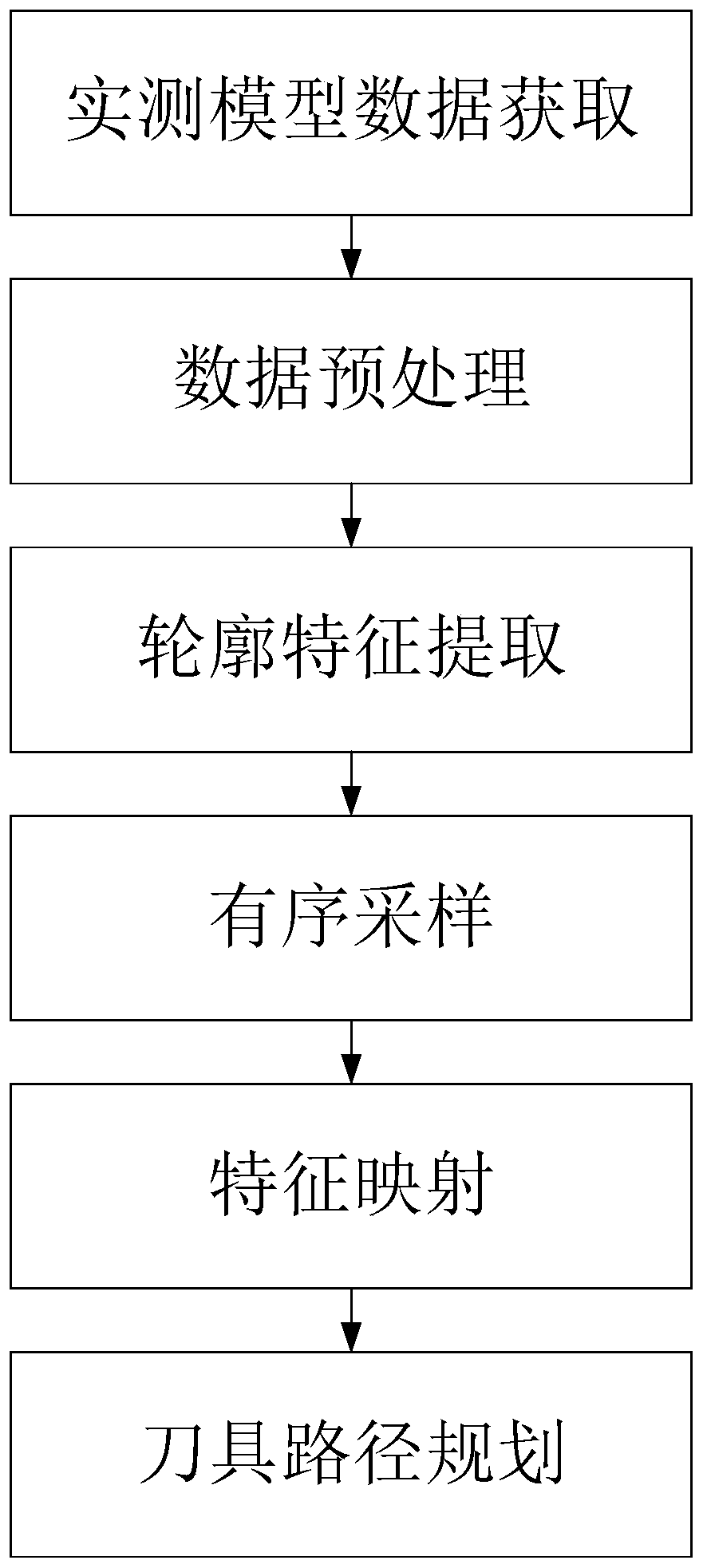

[0043] In order to clarify the technical solution of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

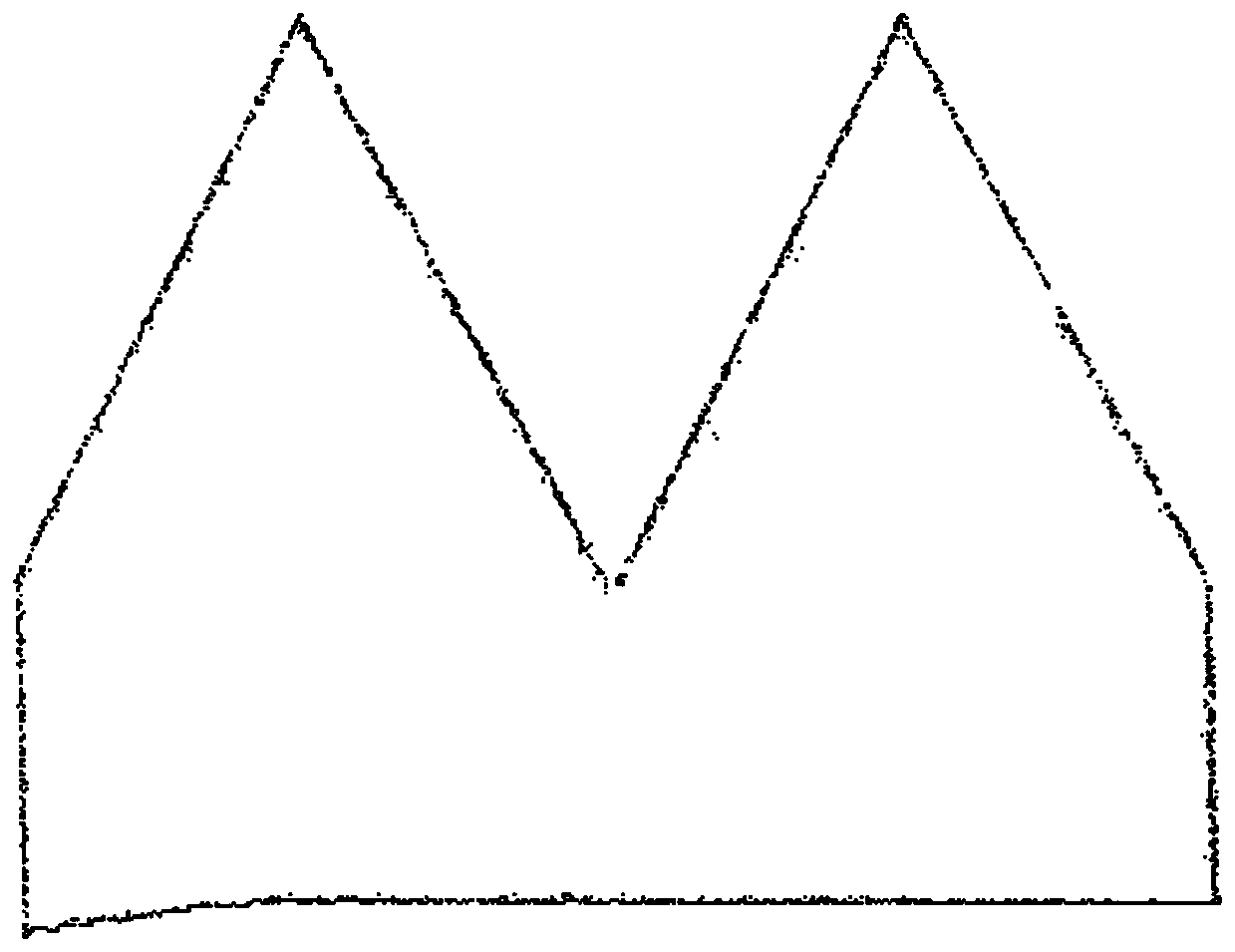

[0044] The present invention is based on the measured data feature-guided parts precision processing method, through the steps of obtaining the measured model point cloud data, data preprocessing, contour feature extraction boundary, ordered sampling and other steps, the ordered sampling results are mapped to the data model as a guide for numerical control The trajectory of machining to improve the accuracy of remachining parts with allowance.

[0045] In this embodiment, a part with a thin-walled structure is taken as an example, and the specific process of the processing method is as follows:

[0046] 1) Scan the reprocessed standard parts with a 3D laser scanner, establish a measured model, and obtain the 3D point cloud data of the measured model, which is recorded as the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap