Manual passing and pushing clamp

A manual, clamp technology, applied in the direction of clamps, manufacturing tools, etc., can solve the problems of inconvenient use, complex structure, not allowed to carry with bare hands, etc., to achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below.

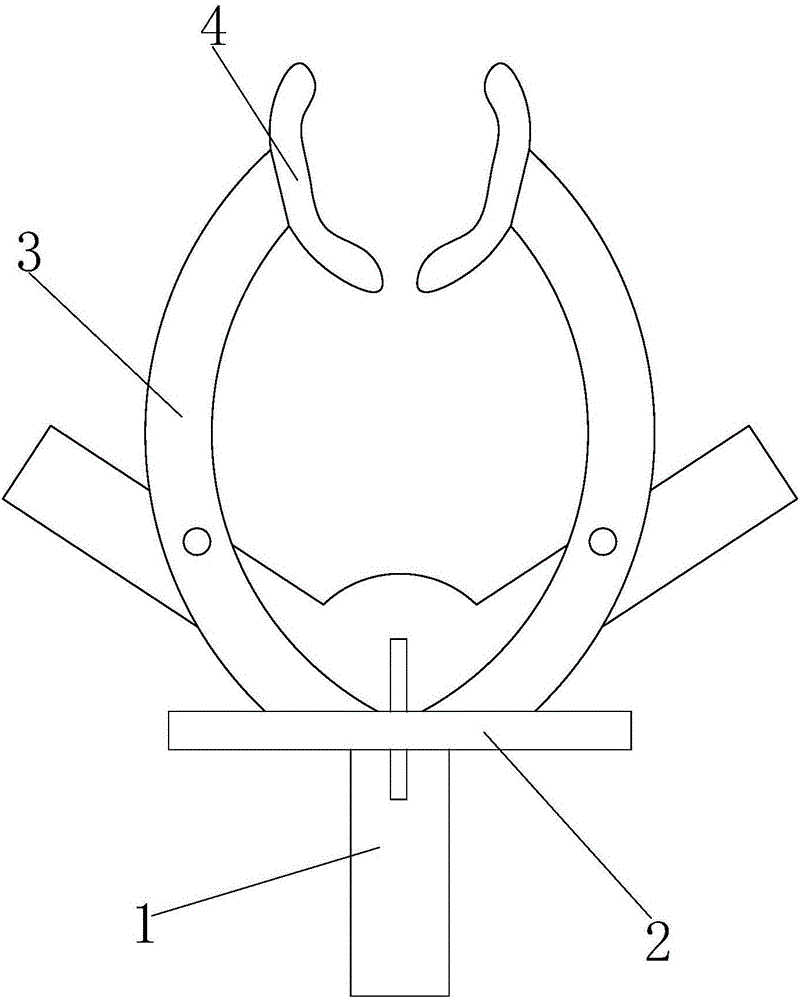

[0012] Such as figure 1 As shown, a manual recursive clamp includes a Y-shaped clamp seat 1. A push frame 2 is slidably mounted on the lower part of the clamp seat 1 in the vertical direction, and the upper end of the push frame 2 is in the horizontal direction. Two arc-shaped clamping rods 3 are slidably installed, the middle position of the clamping rod 3 is hingedly mounted on the clamp seat 1, and the upper end of the clamping rod 3 is provided with a clamping notch 4.

[0013] When in use, it is only necessary to manually pull the pushing frame 2 downwards, so that the two clamping rods 3 rotate around the hinge point between themselves and the clamp base 1, so that the clamping jaws 4 above the two clamping rods 3 Sliding towards each other can grip the object to be extracted.

[0014] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com