Lifting storage platform

A platform and storage technology, used in tool storage devices, pollution prevention methods, chemical instruments and methods, etc., can solve problems such as hitting the staff, affecting the quality of the board, and existing safety hazards, so as to protect the body and increase the safety. The effect of plate storage space and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

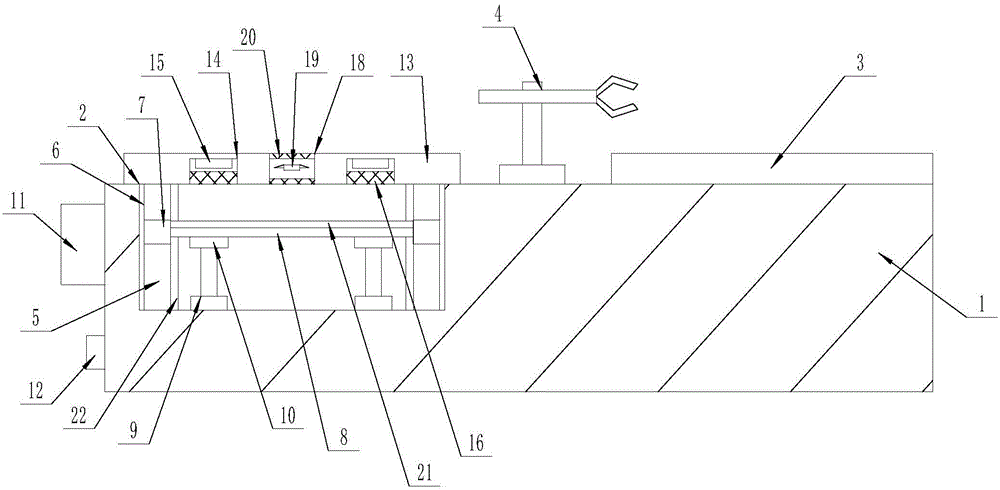

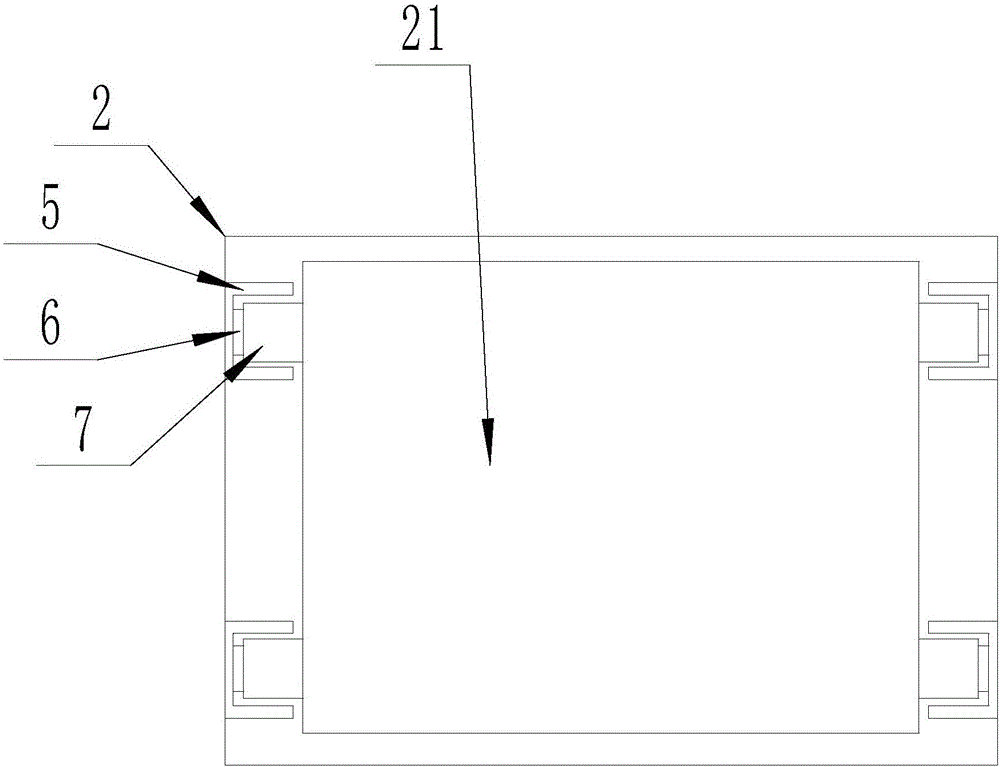

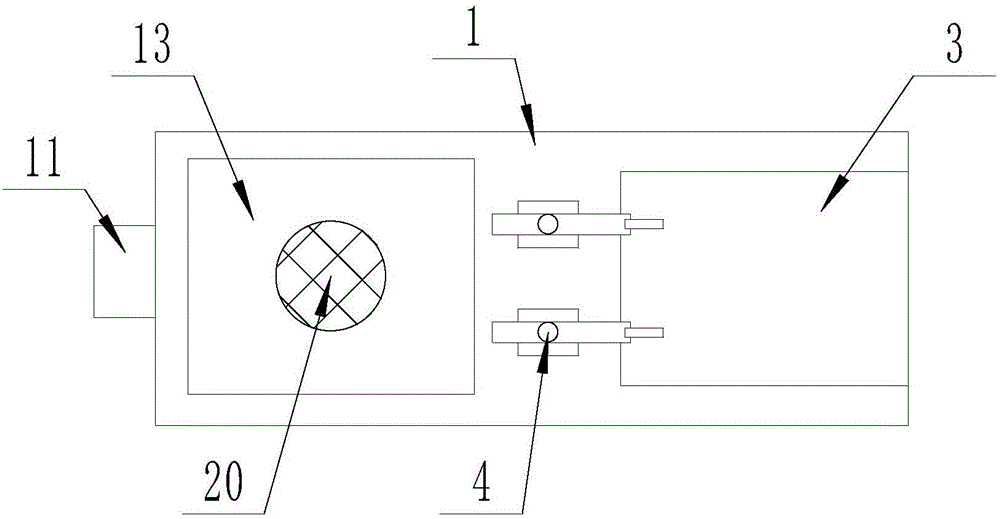

[0017] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, a lifting storage platform includes a workbench (1), one side of the upper surface of the workbench (1) is processed with a rectangular groove (2), and the other side of the upper surface of the workbench (1) is A conveyor belt (3) is provided, and a group of mechanical grippers (4) are arranged between the No. 1 rectangular groove (2) and the conveyor belt (3). On the opposite side surface of the No. 1 rectangular groove (2), A group of vertical slides (5) are all processed, and a vertical slide rail (6) is arranged in each of the vertical slides (5), and each of the vertical slides (6) is provided with slider (7), the upper surface of each slider (7) is jointly connected with a bearing plate (8), and the inner and lower surface of the No. 1 rectangular groove (2) is provided with a group of linear motors ( 9), each of the telescopic ends of the lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com