Rear flat fork

A rear flat fork and head technology, applied in motorcycles, motor vehicles, bicycles, etc., can solve the problems of narrow connection position, limited distance, and increase in the number of mold openings, and achieve the effect of avoiding collision and improving the level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

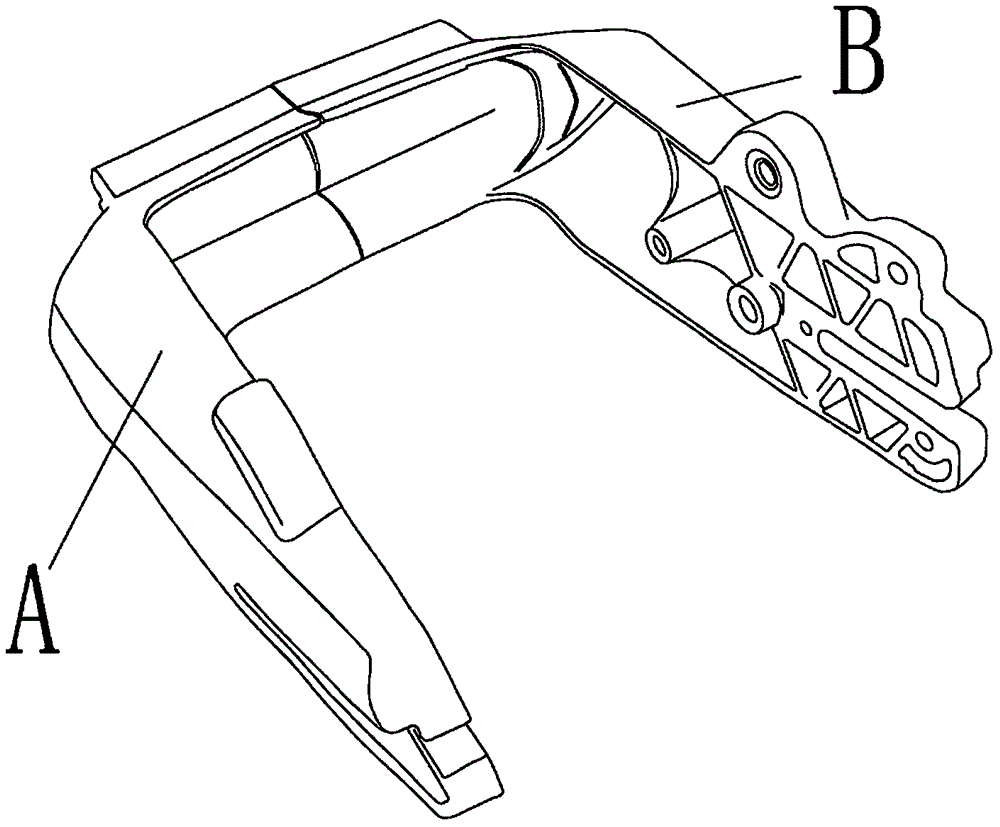

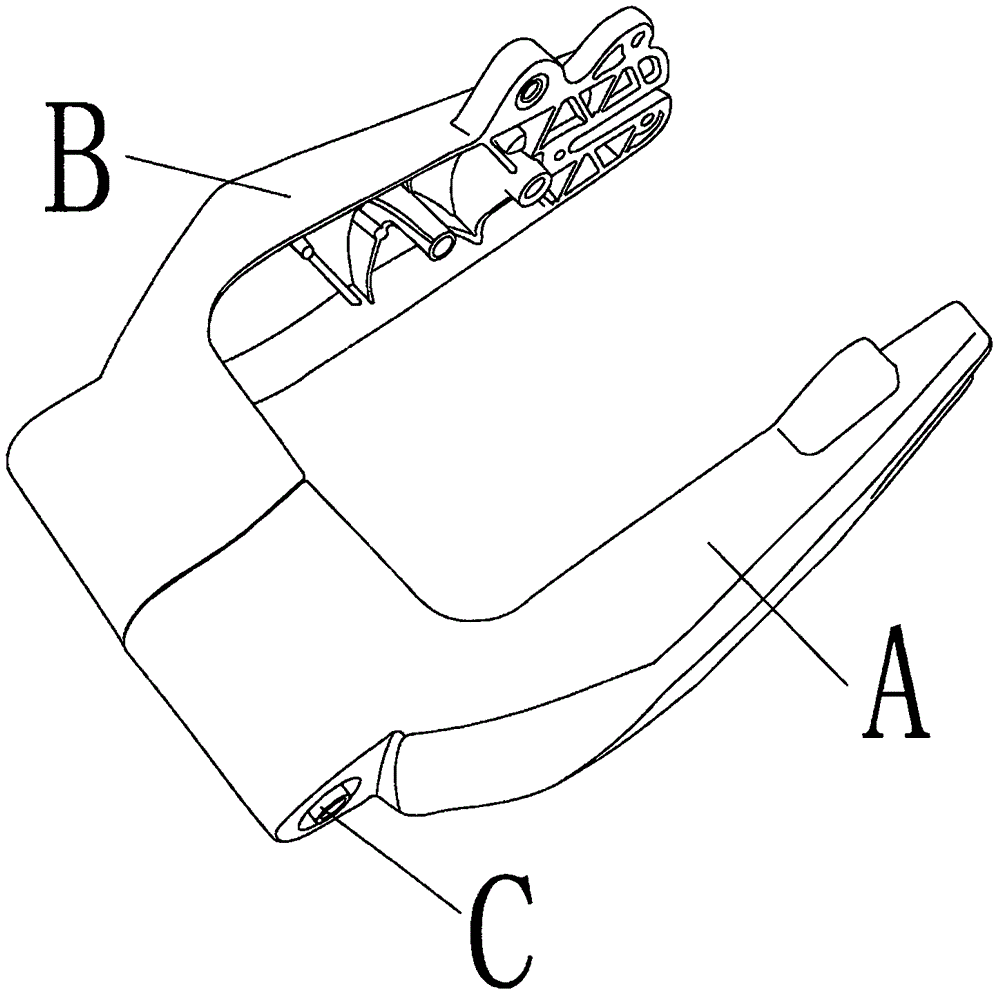

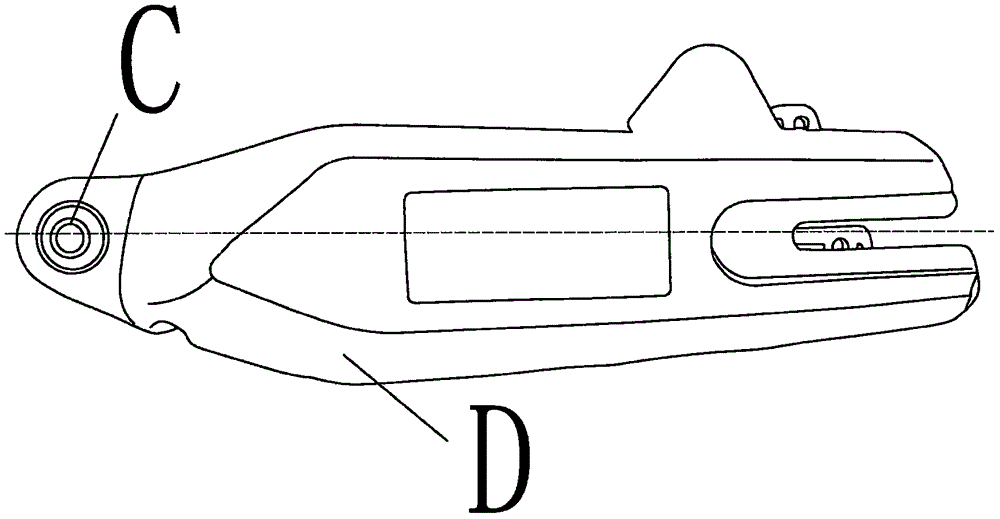

[0028] refer to Figure 4 to Figure 8 , the rear flat fork is made up of the ends of the left and right arms, and the ends of the left and right arms (1, 2) are composed of a head (3) and a shoulder (5), the head The head (3) is hammerhead-shaped, one end is slightly smaller than the other, and the larger end is where the two heads (3) touch each other; there is a neck (4) between the head (3) and the shoulder (5). ), the side (31) of the head (3) can expose the side (41) of the neck (4); through the neck (4), the edge of the shoulder (5) is curved and protrudes upwards (51) It extends obliquely downward toward the end of the side arm, and the head (3) is on the same level as the end of the side arm; on the inner side (52) of the protrusion (51) of the shoulder (5), part of the shoulder body is sunken downward and forms a The slope (54) extending obliquely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com