A kiln entry system and process for co-processing rdf in a cement kiln

A collaborative processing and cement kiln technology, applied to furnaces, lighting and heating equipment, furnace components, etc., can solve problems such as low feeding rate, low equipment utilization, RDF accumulation, etc., to improve the level and increase the amount of feed , The effect of stable air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

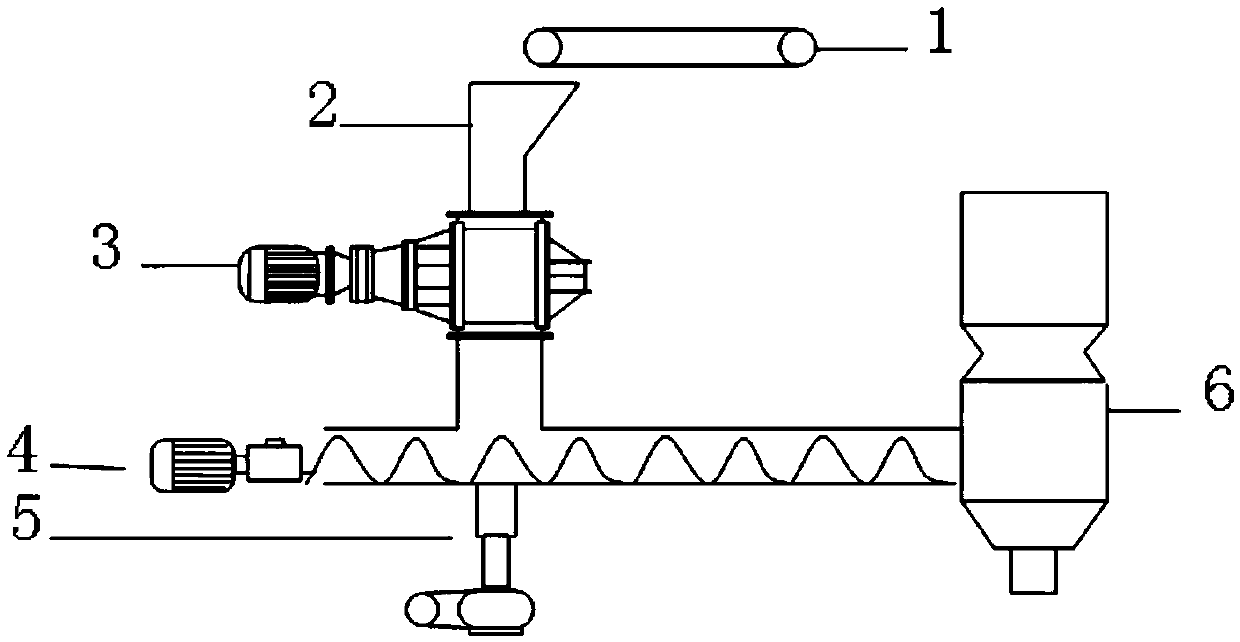

[0013] Such as figure 1 As shown, a cement kiln co-processing RDF entering kiln system and process, refuse-derived fuel (RDF) is transported to the feeding hopper 2 of the RDF entering kiln system by a belt conveyor 1, the feeding hopper is vertically arranged, and the belt conveying device It is installed horizontally above the discharge hopper, the outlet at the bottom of the discharge hopper is connected to the feed port of the rotary discharge valve 3, the RDF enters the rotary discharge valve, and the shaftless reamer conveyor 4 is set on the rotary discharge valve. Below the material valve, the discharge port at the bottom of the rotary discharge valve is connected with the feed port of the shaftless reamer conveyor. The radius of the inlet and outlet of the feeding hopper, the rotary discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com